Track Pad 1000 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Despription of Track Pad 1000 Series

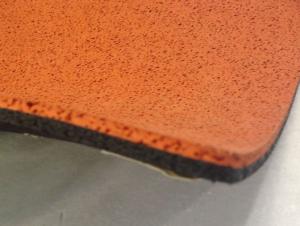

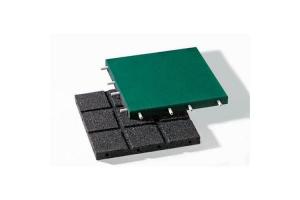

Track Pad 1000 Series are made of 100% recycled rubber granules.

Track Pad 1000 Series are manufactured by factory with the precasting process and 100% recycled rubber roll. The prefabricate rubber roll are equal thickness, balanced elasticity and smooth surface. Besides, it's convenient for transport and carry. It needs a few of labours and easy tools in the process of installation .There in no need of extra large pave equipments. It also reduce the effects of machinery inconvenience and meet the needs of all kinds of tracks' installation.

Features of Track Pad 1000 Series

Equal thickness, balanced resilience

Smooth surface

Excellent ventilate and water seepage abilities

Fine rating of temperature , cold-resistant and weather resistance

Environmental friendly, non-toxic

Recycled and pollution-free

Application of Track Pad 1000 Series

Underlayer of all kinds of athletic tracks.

Parameters of Track Pad 1000 Series

Density (kg/m3):850 900

Hardness (Shore A ): 58 63

Length (m): 10/15/20m ±5cm

Width (m):1m/1.25m ±5mm

Thickness (mm):7-12mm ±0.3mm (adviced thickness )

- Q: Gym rubber floor, rubber floors and plastic floor

- Without scratches on the dance floor is divided into two types: children dance and dance is a special dance adult dance dedicated, in color and thickness is limited (children dance special color dark gray, dark green, light gray, green gray, blue towel) (adult dance special color dark gray, blue. Gray, oak, maple, grey, black, dark green)

- Q: How about rubber flooring Rubber floor

- (4) textile shop (wool carpet, chemical fiber carpet, etc.); (5) wooden floor (log floor, composite wood floor); (6) synthetic material floor tiles (stone plastic floor, rubber flooring, floor leather, etc.)

- Q: The difference between rubber floor and rubber floor Rubber floor pressure

- There are special parameters for standard test residual dent90kg 250 minutes pressure in the area of 1 square centimeters

- Q: Are there any specific standards for the safety of rubber floor

- With anti slip, fitness, beauty and protection. Standard Specification for non skid rubber pads

- Q: What is the price per square metre of rubber floor, rubber flooring toxic

- Different uses! Different life! Different quality! Different price!

- Q: The homogeneous plastic floor and what advantages and disadvantages?

- The main raw material used in plastic floor is PVC material and calcium carbonate, PVC material and calcium carbonate are environmentally friendly non-toxic renewable resources, non-toxic, no radiation. It has long been a large number of people in the daily life, such as water pipes, tableware, medical infusion bags, etc., is a national advocate of green products.

- Q: The floor material used in the store is a rubber floor or a plastic sheet

- Buy plastic floor is a choice of material, how to install the plastic floor, plastic floor price, how much money Shanghai plastic flooring, plastic flooring, plastic flooring manufacturers, professional plastic floor, Fuzhou plastic floor, plastic floor thickness, plastic floor of environmental protection, Hangzhou plastic floor, plastic floor size, plastic floor specifications, plastic floor how much money Nanjing Hefei Yiping, plastic floor, plastic floor

- Q: Production of rubber flooring harmful to the human body?

- Hello This is certainly harmful, because in the rubber production process such as benzene, xylene, hydrogen sulfide, the dust on the human body harm, dust inhalation may lead to formation of industrial pneumoconiosis, benzene can cause cancer, the smell of rubber will cause indoor air formaldehyde exceed the standard!

- Q: What's the difference between a wood floor and a rubber floor?

- And there's no wood. Rubber flooring is not the same as the rubber is absolutely not comfortable.

- Q: PVC floor and rubber floor in the end which is good

- Construction (general) 10 per square meter, packaging materials of $40 per square meter, (Professional) construction of 13 yuan per square meter,

1. Manufacturer Overview

| Location | Dongguan, China |

| Year Established | 2010 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | Western Europe; North America; Oceania; Eastern Asia |

| Company Certifications | ISO 9001:2000;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen, Guangzhou, Hongkong |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese; Korean |

| b) Factory Information | |

| Factory Size: | 5,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered; Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Track Pad 1000 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords