Commercial Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

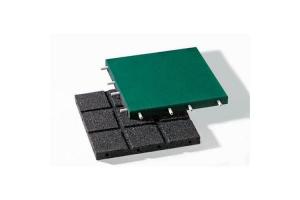

Applications of Rubber Flooring Commercial Series

Office, conference hall, exhibition hall, training center, shopping mall, exclusive agency, colleges, kindergarten, martial arts room, entertainment places, arena, fitness center, gymnasium, Judo and wrestling room, hotel corridor, amusement park, elderly activity center, swimming pool, staircase, stadium stand, locker room, wharf, scaffold footpath…

Properties of Rubber Flooring Commercial Series

· Rich colors, optional shape

· Acoustic & excellent anti-vibration

· Clean and easy maintenance

· Easy installment and eco-friendly

· Anti-bacterium, animalcule

Product Dimensions of Rubber Flooring Commercial Series

Type | Thickness | Width | Length |

Roll, base mat

and material for commercial use | 2mm | 1.22-1.5m | ≤20m |

3mm | 1.22-1.5m | ≤20m | |

4mm | 1.22-1.5m | ≤20m | |

5mm | 1.22-1.5m | ≤20m | |

6mm-20mm | 1.22-1.5m | ≤20m |

Parameters of Rubber Flooring Commercial Series

Specifiaction | Test Method | Test Result |

Overall thickness | 10mm | |

Standard Deformation +40C | DIN 18035/6 | 0.30mm |

Force Reduction +40C | DIN 18035/6 | 13% |

Friction | DIN 18035/6 Dry | 0.84 |

Wet | 0.62 | |

Ball Rebound | DIN 18035/6 | 99% |

Indentation Behavior | DIN 18035/6 | |

Max when loaded | 1.1mm | |

Remainning | 0.11mm | |

Flammability | DIN 51960 | Class 1 |

Tensile Strength | DIN 18035/6 | 1.22N/mm2 |

Elongation at Break | DIN 18035/6 | 46% |

Deformation Modulus | DIN 18035/6 | 4.6N/mm2 |

Shape of Rubber Flooring Commercial Series

shape | standard | thickness | ||

Interlocking | 12″x 12″ | 24″x 24″ | 48″x 48″ | 5-20mm |

Square | 12″x 12″ | 24″x 24″ | 48″x 48″ | 5-20mm |

Hexagon | 12″x 12″ | 24″x 24″ | 5-20mm | |

Dumb Bell | 12″x 12″ | 24″x 24″ | 5-20mm | |

Wind Wheel | 12″x 12″ | 24″x 24″ | 5-20mm | |

- Q: Rubber flooring can be used for home decoration

- However, this is a more practical choice for you, I suggest you choose before the rubber floor, do more contrast to find their own kind of rubber floor bar

- Q: It can be said that a little more specific, the main advantage

- Elastic rubber floor is a green environmental protection floor, no pollution to the environment, no halogen, burning non-toxic fog, is a green environmental protection products. It has a strong antibacterial effect, super wear-resistant, can withstand the test of time, and can guarantee a long time durable, color stability

- Q: What is the meaning of self leveling rubber floor

- Self leveling is to solve the problem of horizon, paving the floor of the need for rubber flooring, if there is a small grain of sand on the ground did not clean up, it will make the laying of the floor uneven. In this case, often make the floor is not wear-resistant, uneven aesthetic enough, look ugly.

- Q: Are there any specific standards for the safety of rubber floor

- With anti slip, fitness, beauty and protection. Standard Specification for non skid rubber pads

- Q: I play badminton on the rubber floor, in order to skid on the shoes coated with rosin, but then the rubber floor on the broken, for cleaning methods! Thank you master

- Do not use rubber floor, and now it is plastic floor with plastic floor, on its own non slip, wear-resistant, as well as flexibility

- Q: The difference between rubber floor and PVC floor

- Other answerRubber floor, as the name implies, which contains plastic and rubber, the floor first appeared in Europe, such as Gerflor's bright excellent series of rubber ground material, this material is mainly comprehensive advantages of plastic flooring and rubber flooring. In China, this kind of material is the main ingredient of waste rubber or plastic, with some in the majority is to act as a rubber flooring sold to customers, this is not in vain. The majority of dealers are doing so, take tens of dollars of domestic rubber flooring as one hundred or two hundred dollars to sell the rubber floor, this material fire performance is poor, it is not mature products.Give you a suggestion, if you want to buy rubber flooring, try to choose European imports of products. Or buy a plastic floor or rubber floor.

- Q: Construction technology of rubber floor

- Installation is prohibited under the temperature of 10 degrees celsius.All the ground floor must be dry, flat, non crack, well constructed, and clean. No dust, paint, wax, lubricating oil, grease, asphalt, old adhesive and other foreign material.The rubber floor adopts the seamless splicing, the stitching seam is straight, smooth and firm.

- Q: How to clean the rubber seal on the solid wood floor?

- Aggrandizement wood floorLaminate flooring maintenance is much simpler than solid wood flooring. When cleaning the floor, it is necessary to pay attention to keep the floor dry, do not use a lot of water flushing, pay attention to avoid local long-term immersion in the floor. Clean the stain when using neutral cleaning agent to avoid direct sunlight, rain, moisture, etc.. In addition, pay attention to indoor ventilation, indoor temperature is also conducive to extend the life of the floor. Do not need to strengthen the floor paint and waxing, and solid wood flooring is different, do not use sandpaper polishing.

- Q: How to deal with the paint on the rubber floor

- The official name is thinner, thinner or solvent oil, usually colorless transparent liquid, commonly known as banana water.

- Q: PVC floor and rubber floor in the end which is good

- The material is of high wear-resistant floor rubber products, the main types of floor glue is too much, please choose the site of special products, if you are a family choose stone plastic sheet, choose the mall commercial airport pure material, rubber flooring, floor board special dance dance, rubber floor has a high requirement for the quality of the ground, the ground should be flat. No sand, dry ground, ground cracks, no different use requirements, main floor glue fire, anti-skid, environmental protection, easy to clean, variety, fast construction, long service life, our factory production of the special plastic Mio dance floor, if so we can provide samples for reference, to the membrane of different thickness different price you want, our dance floor (dance floor, many kinds of special).

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2002 |

| Annual Output Value | US$ 50 Million - US$ 100 Million |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Commercial Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords