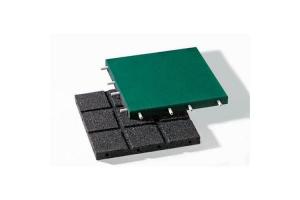

Aturf Pad 1000 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Aturf Pad 1000 Series

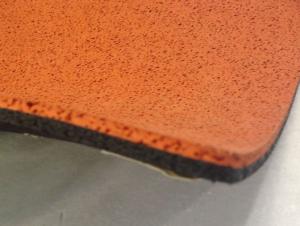

Aturf Pad 1000 Series are made of 100% recycled rubber granules and rubber threads.

Aturf Pad 1000 Series are manufactured by factory with the precasting process and 100% recycled rubber roll. The prefabricate rubber roll are equal thickness, balanced elasticity and smooth surface. Besides, it's convenient for transport and carry. It needs a few of labours and simple tools in the process of installation .There is no need to have the aid of any equipments. The good resilience offer the players with better buffer and protect with collision and fall.

Features of Aturf Pad 1000 Series

Fine resilience

Equal thickness, adjusted hardness

Excellent ventilate and water seepage abilities

Fine rating of temperature , cold-resistant and weather resistance

Environmental friendly, non-toxic

Recycled and pollution-free

Applications of Aturf Pad 1000 Series

Resilient and protective layer of various kinds of artificial turf( such as football, rugby, 5 people football, hockey, golf), buffer layer of kinds of machinery.

Parameters of Aturf Pad 1000 Series

Density (kg/m3):750 800

Hardness (Shore A ):45-50 58

Length (m):10/15/20m ±5cm

Width (m):1m/1.25m ±5mm

Thickness (mm):10-15mm ±0.3mm (adviced thickness )

- Q: It can be said that a little more specific, the main advantage

- At the same time has strong sound-absorbing performance, to maximize the absorption of noise and echo, the national detection, the sound absorption can reach 13 dB value, especially suitable for the requirements of quiet working environment; secondly, Mutong rubber floor super slip, safe and reliable, can alleviate the impact force

- Q: Rubber floor cracks with what glue?

- 2 unscrew the front cover, according to the above description of the weight ratio of A agent + B agent can be used to stir evenly (A:B=2:1); in order to ensure the use of the effect, but also can be used to draw a vacuum.

- Q: Are there any specific standards for the safety of rubber floor

- The utility model is suitable for hotels, hotels, gymnasiums, meeting rooms, gymnasiums, kitchens, warehouses, toilets, etc.

- Q: The difference between rubber floor and plastic floor

- [PVC floor and rubber floor] color difference: rubber flooring is more difficult, because the rubber has a strong color, so most of the rubber floor color is relatively simple

- Q: Are there any specific standards for the safety of rubber floor?

- And comply with all international standard BS6853 (total weight of toxic poisonous smoke R), NF*10-702 and ASTME662, with UNI8457 and UNI9174 standard, and is a standard product, according to the DIN4102 standard, this kind of product has reached B1 level and NFP92501 M3 level

- Q: The main features of rubber flooring

- Rubber floor, a floor of natural rubber and other synthetic rubber. In appearance, it is bright and bright color, soft texture, like rubber, suitable for sports as a foreshadowing of sports. As a ground decorative material, rubber flooring has been popular in developed countries for decades, and has been widely used. In our country has just arisen.

- Q: Plastic floor and wood floor which is good?

- What do you use is mainly to see the if used in sports or dancing etc. now in Chinese currently more professional or plastic floor because wood flooring is not environmental protection and noise of the runners not buffer or protection

- Q: What are the product standards of rubber flooring

- What are the product standards of rubber flooring

- Q: Rubber flooring, how much a square! Do you know?

- More than 10 yuan per square meter to more than 400 yuan per square meter of imports are. The main difference in the price of plastic floor wear-resisting layer.Is it possible to solve your problem?

- Q: The basketball court is a rubber floor, there are a lot of black dirt on the top, washing powder and hot water are not working, I would like to ask which brother know what method can be removed?

- With water and kerosene on the "rubber and iron mill our results are good

1. Manufacturer Overview

| Location | Dongguan, China |

| Year Established | 2010 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | Western Europe; North America; Oceania; Eastern Asia |

| Company Certifications | ISO 9001:2000;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen, Guangzhou, Hongkong |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese; Korean |

| b) Factory Information | |

| Factory Size: | 5,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered; Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Aturf Pad 1000 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches