Courts Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

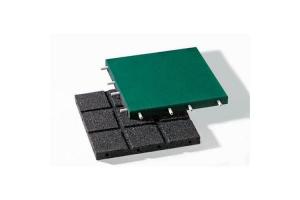

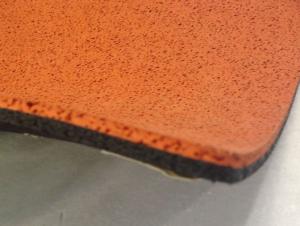

Description of Rubber Flooring Courts Series

Rubber Flooring Courts Series is an extremely durable, tough, non-porous, non-skid rubber mat that can withstand heavy industrial and commercial use. It will resist tearing, cutting, freezing, and reduces noise levels. Ice does not stick to it and it can be permanently laid on wood, metal, tile, and concrete surfaces. This sport mat is made recycled rubber flooring offers the perfect choice for slip resistance, sound absorption, and comfort.

Applications of Rubber Flooring Courts Series

Subdistrict courts, school and college tennis, badminton, basketball courts...

Properties of Rubber Flooring Courts Series

· Prefabricated in factory, uniform thickness.

· Moderate hardness, durable.

· Adapt to all-weathers, anti-UV and hydroxylation.

· Excellent elasticity and air-permeated.

· Be able to glue with different top coatings, such as: PU, Acrylic, Si-PU, saving base material.

Product Dimension of Rubber Flooring Courts Series

Type | thickness | width | length |

Rubber roll,

base mat and material for courts | 2mm | 1.22-1.5m | ≤20m |

3mm | 1.22-1.5m | ≤20m | |

4mm | 1.22-1.5m | ≤20m | |

5mm | 1.22-1.5m | ≤20m | |

6mm-20mm | 1.22-1.5m | ≤20m |

- Q: The difference between rubber floor and plastic floor

- PVC floor and the color is very much, can be any combination, can give designers more choices.

- Q: Gym special rubber floor for how much a square meter

- Gym special rubber floor 65 yuan per square meter.2, rubber floor is natural rubber, synthetic rubber and other components of the polymer material made of floor. SBR, high benzene, butadiene rubber is synthetic rubber, oil products

- Q: Are there any specific standards for the safety of rubber floor?

- And comply with all international standard BS6853 (total weight of toxic poisonous smoke R), NF*10-702 and ASTME662, with UNI8457 and UNI9174 standard, and is a standard product, according to the DIN4102 standard, this kind of product has reached B1 level and NFP92501 M3 level

- Q: Rubber floor price per square meter

- Quality price: the current domestic rubber flooring quality and the quality of foreign rubber floor

- Q: What is the difference between the pure rubber floor and the sports floor glue

- Pure rubber flooring expensive ah! 2 mm to be $150 a square meter, too can not afford to buy, the price of cheap sports floor, the best is only $180 or 5 mm! Removable, removable, more styles

- Q: What's different about the material? Five

- As the name suggests, rubber flooring is made of natural rubber, synthetic rubber and other ingredients made of polymer materials. SBR, high benzene, butadiene rubber is synthetic rubber, oil products. Natural rubber is a rubber tree that is grown from a rubber tree. Rubber flooring is environmentally friendly floor, because all the materials are non-toxic environmentally friendly materials and polymer materials.

- Q: Plastic floor and wood floor which is good?

- What do you use is mainly to see the if used in sports or dancing etc. now in Chinese currently more professional or plastic floor because wood flooring is not environmental protection and noise of the runners not buffer or protection

- Q: What is the price per square meter of rubber floor

- Specific prices need to look at what kind of material is done, there are breathable, mixed type, composite type, prefabricated, etc., in addition to the specific thickness, different thickness of the price is also different

- Q: Kindergarten rubber floor is too thick to do

- Its environmental protection is no need to worry about. Any qualified PVC floor needs to pass IS09000 international quality system certification and ISO14001 international green environmental protection certification.

- Q: What is the production process of rubber flooring

- Self leveling cement ground leveling, dry ground, surface grinding, surface cleaning, size, material beach open 24 hours after the start of pavement, dry rubber cutting place, scraping, put the material sticking board, smooth compaction, welding, repair, cleaning, acceptance, qualification, use. The need for professional installation of plastic floor laying

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2002 |

| Annual Output Value | US$ 50 Million - US$ 100 Million |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Courts Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 x 20' GP m²

- Supply Capability:

- 50 x 20'GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches