TP-PF Series Semi Automatic Powder Auger Filling Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of TP-PF Series Semi Automatic Powder Auger Filling Machine

This type can do dosing and filling work. Due to the special professional design, so it is suitable to the fluidic or low-fluidity powder and small granules materials,It is widely used in food manufacturing, pharmaceutical manufacturing and other fields, Like instant coffee powder, formula milk powder, flour, proteins, flavors, sweetener, condiment, solid drinks, veterinary drugs, dextrose, pharmaceuticals, ,talcum powder, agriculture pesticide, dyestuff, and so on.2. Main features

- Lathing auger screw to guarantee the precise filling accuracy

- PLC control and touch screen display

- Servo motor drives screw to guarantee stable performance

- Split hopper could be washed easily without tools

- Can be setting to semi-auto filling by pedal switch or auto filling

- Full stainless steel 304 material

- weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials' density change.

- Save 20 sets of formula inside the machine for later use

- Replacing the auger parts, different products ranging from fine powder to granule and different weight can be packed

- Multi language interface

3.Technical parameters

| Model | TP-PF-A10 | TP-PF-A11 | TP-PF-A11S | TP-PF-A14 | TP-PF-A14S |

| Control system | PLC & Touch Screen | PLC & Touch Screen | PLC & Touch Screen | ||

| Hopper | 11L | 25L | 50L | ||

| Packing weight | 1-50g | 1-500g | 10-5000g | ||

| Weight dosing | By auger | By auger | By load cell | By auger | By load cell |

| Weight feedback | By off-line scale ( in picture) | By off-line scale( in picture) | Online weight feed back | By off-line scale(in picture) | Online weight feedback |

| Packing accuracy | ≤100g, ≤±2% | ≤100g,≤±2%; 100-500g,≤±1% | ≤100g,≤±2%; 100-500g,≤±1%;≥500g,≤±0.5% | ||

| Filling speed | 40-120 times per minute | 40-120 times per minute | 40-120 times per minute | ||

| Power supply | 3P AC208-415V 50/60HZ | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | ||

| Total power | 0.84 KW | 0.93KW | 1.4KW | ||

| Total weight | 90kg | 160kg | 260kg | ||

| Overall dimensions | 590*560*1070mm | 800*790*1900mm | 1140*970*2200mm | ||

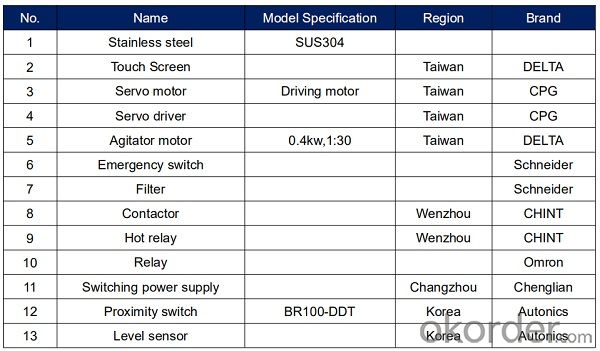

4. Configuration list

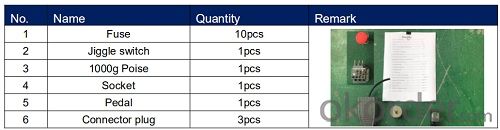

Accessories

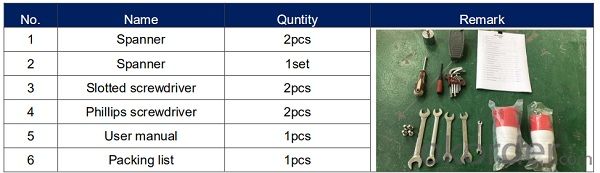

Tools box

5. Detail images of the machine

-Level sensor----tuning fork type level sensor, P+F brand, it is more suitable for all kinds of materials, especially dusty materials.

- Feed inlet & air outlet----feed inlet with radian to reduce impact for hopper; Air outlet with quick connection type, more convenient installation and dis- assembly.

-screw way to fix metering auger in the hopper----It will not make material stock and easy for cleaning.

-Height adjust handwheel for filling nozzle----It is suitable for filling into bottles/bags with different height.

6. Remark

- One year warranty, life-long service

- Provide accessory parts in favorable price

- Update configuration and program regularly

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q: What are the main functions of packaging machinery and equipment?

- Packaging machinery can be realized in the packaging process, including filling and wrapping,

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine machine standard price of about 38000, excluding tax, tableware packaging machine is designed for tableware (e.g., chopsticks, bowls, dishes and so on) a modern packaging machinery packaging, this machine is mainly composed of conveyor, packaging machine, output machine, shrink machine, composed of four parts.

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- Ceramic wall and floor tile is a special term used in building ceramics industry. It refers to the ceramic tile used for paving internal walls, exterior walls and floors.It includes:Glazed tiles: white glazed tile, colored shaddock tile, embossed glazed tile, mottled glazed tile, patterned glazed tile, mural glazed tile.Floor tile: paving brick, red floor tile, ceramic mosaic tile (ceramic mosaic), ladder brick.The exterior wall tiles, glazed tiles, glazed tiles, imitation brick, brick from #.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- This is really not sure, it can be said that any group, as long as the packaging products are required to use packaging machinery. Most of the products are now in need of packing. So it can be said that any group.

- Q: What is the working principle of the pillow packing machine?

- The sealing form - bag two sealing, a middle sealing surface,

- Q: What are the structures of the packaging machinery?

- Is a company engaged in outsourcing clients, packaging, processing, packaging equipment, leasing, services, sales in one of the specialized companiesSales of second-hand packing equipment according to the customer's product features and requirements. Reduce customer purchasing costsAccording to the customer's product characteristics and requirements. Select the best packaging equipment for customers, reduce customer purchasing costsPackaging equipment spare parts sales and maintenance services

- Q: What is a packaging machine?

- Well, before and after the associated processes, such as cleaning, stacking and disassembly. In addition, the package also includes the measurement or in the processes of stamp packages. Mechanical packaging products can improve productivity, reduce labor intensity

- Q: Energy saving reform of packaging machine

- First, the working principle of food packaging machinePillow type automatic packaging machine of the present domestic leading and most mature and reliable design and production technology, the essence of a collection of many years of experience in the field of packaging machinery, the packing machine can be used in a variety of composite packaging film coil on the packaging of bulk food, very suitable for the majority of users need to Chinese. 1) the electrical parts of the automatic packing machine are usually made up of the following parts:

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

TP-PF Series Semi Automatic Powder Auger Filling Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords