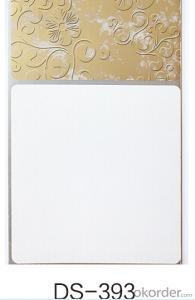

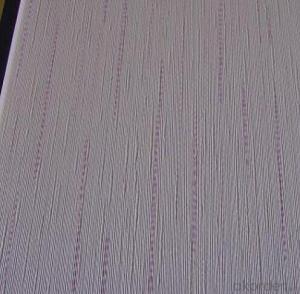

Top T PVC Ceiling - New Design PVC Laminated Panel for Room Decoration

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 550000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

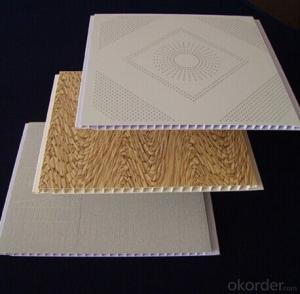

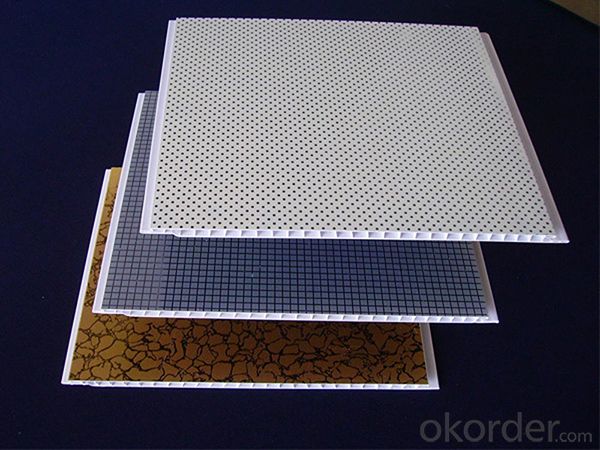

PVC Laminated panel New Design for Room Decoration

Main material:

PVC (50%, 60%, 70%, 85% or as your request), Caleium Carbon and other chemicals

Usual

specification

Length: customized size, such as 2.95m, 3m, 3.8m, 5.6m, 5.8m, 5.95m

Width: 5cm to 40cm or customized

Thickness: 5mm to 10mm or customized

Surface treatment

Oil print, hot stamping foil, thermal transfer print, laminated and so on as your pattern and color

Surface effect Bright/glossy, high glossy, matt, gleam, roller coating and so on

Production quality

Light of weight, powerful strength, high intensity, heat insulation, flame resistant, corrode resistant, age resistant, no aspiration, easy cleaning, easy installing and so on

Producing scale

With more than 60 PVC production lines and 100 kinds of moulds

Certificate

ISO9001:2000, Soncap, Intertek certificate

Application

Hotels, commerical buildings, hospital, schools, home kitchen, bathroom, indoor decoration and so on

Sample Free with International Express Delivery

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures

- Q: PVC board how rub rub

- Solid wood cabinet to pay attention to moisture, PVC cabinets should pay attention to corrosion, both of the service life is very high.

- Q: What is the cold mounted board

- KT board is a PS foam sheet, the board is crisp, light, easy to degenerate, easy to process, and can be directly on the board screen printing, paint (need to detect paint adaptability) and inkjet, widely used in advertising, Decoration, culture and art and packaging. The use of advertising is used for product promotion information dissemination of the exhibition, display and notice with mounting liner, the other is a large number of applications used in a screen printing, especially for a wide range of unified publicity activities carried out. KT board from the current more mature production process can be divided into cold composite and thermal composite, these two different products produced by the corresponding product called (cold composite board) cold plate - commonly known as cold mounted board and (hot composite board Hot plate - the KT board. Cold plate production process, the first is the core foam: the raw material is PS particles, but because the cold plate is mostly single-layer board core, so to double foam, the first foam thickness is generally about 3.5mm, ripening After half a month, and then the second foam, the core into the device foam to 5.0-5.2mm or so, the second foam can be directly after the paste paste. And then paste the dough: dough the substrate is PVC, usually 0.08m-0.1mm, 0.9 × 2.4 small plates are mostly used 0.08-0.1mm dough, 1.2 × 2.4 large plate generally use 0.16mm dough to strengthen the board Stiffness, because the surface is PVC, the core is the PS material, so the choice must be neutral glue, glue in the dough and the core at the same time glue each other paste, paste to the plate hydraulic press (more than ten tons) squeeze, more than 24 hours Can be taken out trimming trim shipping. Yichang area commonly used cold plate is mainly 1.2 × 2.4 large board, 0.9 × 2.4 small board is now rarely seen on the market.

- Q: across ceiling joists and then down 12 feet to a generator. I live in a town of 50,000 and it may or may not be union labor

- PVC is not allowed by code for a gas line. It is too easy to break, from an earthquake or other physical abuse. You need to use black iron pipe or the newer flexible pipe systems that have become available. The cost depends upon local labor conditions and how difficult the attic access may be, but a ballpark price might be $1000.

- Q: Metal and PVC board how to use what bonding

- Universal glue, glass glue

- Q: On the PVC plastic plate pressure groove

- It is very simple, you want to weld is not a hot air gun? First punch, and then the front and back bake soft, pay attention to the distance away, do not bake coke, crack, bubble, to be a corresponding size of the lumps (male) and bowl-shaped plate (female), and then baked a good plate Put on a good position, with the Yang model hammer or stamping is not enough

- Q: Pvc floor construction costs how much money a square meter

- PVC sheet flooring is generally 4 yuan / square meter, PVC membrane floor general 7-10 yuan / square meter (depending on the degree of ease of construction of the floor), self-leveling construction is generally 2-3 yuan / square meter. Different regions, how much the price difference between the larger.

- Q: PVC crust foam board business standards or national standards

- The true crust is made with a stoppage method, which forms a layer of dense hard crust on both sides of the sheet, which can improve the hardness and nail force of the plate. These physical properties are very important for the manufacture of furniture or for the decoration of the house. To identify the PVC board is (really) crust, in fact, very simple! As long as the shop does not pay attention to the thumb with the nail on the PVC board pressure, and then carefully check whether there is a deep dent, if there is, is clearly false, it is best not to. Celuka (Celuka) also known as controlled foam method, the current application is very wide, by the French gine kulmann company invented, it is the first patented one of the extrusion foam molding method. The principle of the Luca method is that the outer skin of the melt is compressed and cooled in the styling device directly connected to the die, and the mandrel in the cavity ensures that there is room left when the extrudate leaves the die Through the melt in the mold within the free foam is filled. Cooling strength, core mold size, extrusion speed, can affect the foam core layer density and outer crust thickness. The complex shapes of the profiles produced in this way have the characteristics of low density, high hardness and smooth surface. Baotian Hi-Tech can visit, in addition to their production of PVC crust foam board, but also the production of PVC own foam board, PVC foam profiles, product quality is in the high-end.

- Q: KT board and PVC board, as well as ABS board What is the difference between ah

- Kt board is polystyrene material (lunch box material) foam out of the plate, the biggest feature is the light mainly used for indoor advertising; Pvc plate - also known as pvc foam board or Andy board, its chemical composition is polyvinyl chloride. Widely used in passenger cars, train car roof, box core layer, interior decoration board, building exterior panels, interior decoration board, office, residential, public places building compartment, commercial decoration rack, clean room board , Hot plate, special cold-keeping project, environmental protection board mold, sports equipment, breeding materials, and other materials, the use of anti-corrosion, , Beach water-proof facilities, water-resistant materials, art materials and a variety of lightweight partitions instead of glass ceiling. (The general plastic pipe with this material is called pvc but not foam) ABS board ABS board ABS board is a new material in the sheet industry. Its full name is acrylonitrile / butadiene / styrene copolymer plate. English name Acrylonitrile-butdiene-styrene, is the largest production, the most widely used polymer. It will PS, SAN, BS various properties organically unified, both tough, hard, just equal balance of excellent mechanical properties. (Refrigerator, air conditioning these are used in this material)

- Q: Pvc buckle board, installed smallpox, the specific steps, must be detailed, to DIY Kazakhstan

- Hello, the following began to hang pvc buckle board ceiling. Material; pvc buckle plate, pvc trim corner, card main dragon, deputy dragon Tools; impact drill, glass gun, glass glue (porcelain white) self-tapping screws, screwdriver, 6 PCT top burst, 8% impact drill, 6% screw, 6% nut, Start construction; first set a point in the porcelain wall, see the ceiling hanging high, and then hit the water, in the pvc trim corner sticking glass glue, and then stick in the flat water line, the angle and the outer corner is more trouble. And then side by side in the zeal hit 4 holes, (8% impact drill) installed 6% burst, remember to open the top. And then from the top of the ceiling to pvc trim angle, the height is 6% screw to cut the length of the cut in the 4 4 4 screw at one end of the twist nut, and now began to card on the main dragon, and then the deputy dragon Hanging out, so that the ceiling board ceiling out of the shelf.

- Q: My daughter inside the floor of the house is a little green light green point of the PVC board, would like to ask what color with a warm wall

- Pale yellow. Brush latex paint colored cards, choose their own on the line.

Send your message to us

Top T PVC Ceiling - New Design PVC Laminated Panel for Room Decoration

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 550000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords