TOBOND exterior wood wall panel/ interior wood wall cladding/ alucobond panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

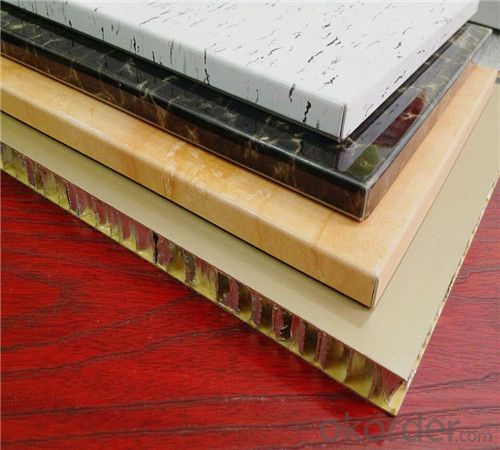

TOBOND PVDF ALUMINIUM COMPOSITE PANEL

TOBOND PVDF plus Aluminium Composite Panel is special metal surface wall cladding material, compounded with superior aluminum and LDPE Plastic.

Comparing to traditional metal panel, TOBOND ACP is with prime performance of economic efficiency, environment friendly and flexible installation.

ADVANTAGES OF TOBOND ACP

High strength, easy maintenance, 20 years not color fade.

Easy fabrication and installation.

Good Impact Resistance.

Light weight and rigid, reducing buildings load, good performance for quakeproof.

Good Smoothingness.

Various color and size for option.

TOBOND ACP Application

Outer wall cladding, curtain wall.

Redecoration of old buildings outer-wall.

Balconies, indoor partitions.

Units wall cladding

Advertisement signboard

Kitchen and bath room ceiling

Kitchen Cabinet surfacing decoration

Industrial Usage, Vehicle bodies.

STANDARD SIZE OF ACP

Series | Coating | Usage | Panel Thickness | Panel Size(mm) |

PVDF Plus Outdoor Panel | PVDF | Exterior Wall Cladding | 4mm /3mm | 1220*2440 1220*2900 |

Indoor panel | Polyester | Interior Decoration/ Advertisement board | ||

Fireproof panel | PVDF/Polyester | Exterior Wall Cladding/Interior Decoration | ||

Special Size For Option | 6mm/5mm | 1250*2900 1500*2900 1500*5800 | ||

Proceeding Noticed

Portage: panel must be uplifted with its four borders at the same time during portage, do not drag and whop for fear scraping surface of the panel.

Storage: panel must be stored in cool dry place, and placed on flat surface.

Notching; if notching with notching equipment or gong equipment, using milling cutter with half round head≥90 degree. When notching, pls leave 0.2—0.3mm thickness plastic core materials bending with aluminium sheet to increase intension and tenacity, otherwise aluminium sheet may rupture or coating crack.

Bending: forcing equably when bending, molding one-off, do not bend again and again, or Aluminium panel may rupture.

Arcing Machining: using professional bending equipment to machining, forcing inchmeal to make the panel reaching bending radian needed. Do not bending one-off.

Batch: same color panel from different batches may have chromatic aberration, contrast process of chromatic aberration should be added if selling or using panels with different batches panels. Panels can be placed on a plane only there may be visual chromatic aberration.

Installation direction: panels must be install in same direction.

Ripping film: the protective film should be ripped away within 45 days after installation, to avoid survivors left.

Cleaning: clear the panel with water, scours or alcohol over98% with soft sponge. Do not use Chemical Solvents.

- Q: China aluminum-plastic plate door decoration materials, where to buy a good point? Have prawn help?

- To Kunming cloud like building materials to buy, they are a set of aluminum-plastic plate, aluminum veneer production and wholesale as one of the large curtain wall decoration materials business, the introduction of the quality of aluminum-plastic plate is very good.

- Q: Yueyang where to buy aluminum-plastic plate, which the market has aluminum-plastic plate sales

- December Xunyi mechanical and electrical market part of the shops opened, when the major hardware and mechanical have. Now you can go to the sun bridge big market or Dongting Building.

- Q: Alpha aluminum composite plate which country

- Aluminum-plastic plate as a kind of high-tech composite materials products, since the sixties of the last century in the European research and development has been more than 30 years of history, its various properties are constantly improving and improving the use of a wide range of products Exist in the transport industry, the construction industry and some special line industry, such as advertising industry. Especially in the construction industry, because of its light weight per unit area, relatively high strength, easy processing and installation, so get a very common application. From the interior to the interior decoration, from low-rise buildings to high-rise buildings, can be seen in the shape of aluminum-plastic plate. At the same time, foreign applications in the aluminum plate process has a very strict and proven operating practices, to ensure that the aluminum plate can be used correctly. Especially when the product is applied to the building, its product certification and use of the unit must strictly comply with the relevant norms. As a result of strict certification system, so nearly three decades, the application of foreign composite aluminum-plastic plate, especially in Europe, have been moving forward, new products and new systems continue to emerge.

- Q: Do aluminum-plastic plate wall, dry hanging way. Is a government project. There are 4,000 square meters. There are embedded parts. No frame, package package material how much appropriate ah

- No matter what kind of structure of the aluminum-plastic plate, 80 yuan / square meters is enough. The rest is the cost of artificial and accessories accessories.

- Q: About the introduction

- Fire board, also known as fire board, or high pressure decorative panels. It is the kraft paper impregnated in the resin, after high temperature and high pressure treatment, the production of interior decoration surface materials. With wear resistance, heat resistance, impact resistance, acid and alkali resistance, smoke burning, fire, anti-bacterial, anti-mildew and anti-static characteristics. Fire board is generally used for table, desktop, wall, cabinets, office furniture, hanging cabinets and other places. Common specifications: 2135mm × 915mm, 2440mm × 915mm, 2440mm × 1220mm, thickness 0.6-1.2mm.

- Q: Does the aluminum plate itself fire? Not aluminum plate

- More than their own melting point. It will not fire

- Q: A piece of aluminum, length is 2 meters, width is 1 meter, seeking a few parties?

- By the area formula S = a.b get S = 2 × 1 = 2 (m?) is 2 square meters.

- Q: The market for aluminum-plastic plate processing machines so much, which brand is good?

- I know this problem, I'll tell you about it ~ This style is a lot of the price is different, mainly to see the quality, it is recommended that you go to the market to see, choose a few more, to be a comparison. I recommend the United States of America Maidike Mulitcam large CNC aluminum-plastic plate processing center for a variety of thick / thin aluminum, aluminum-plastic panels, aluminum curtain wall, aluminum honeycomb board, aviation yacht with aluminum cutting, drilling, modification and other processing, Kind of processing features hope to help you! Have a reference to you

- Q: Hello, how do you contact me? Need green aluminum plate, thank you!

- For a new color lack of industry chain support.

- Q: Want to put the silicone plate into a right angle u line stick to a box outside, now do not know how to get that corner, will not use a wallpaper knife point it, cutting the kind of tool can use aluminum? Everyone who knows, tell me, thank you ah.

- You can cut the kind of aluminum-plastic plate tool, but the aluminum-plastic plate was 5mm Oh How thick is your silicone?

Send your message to us

TOBOND exterior wood wall panel/ interior wood wall cladding/ alucobond panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords