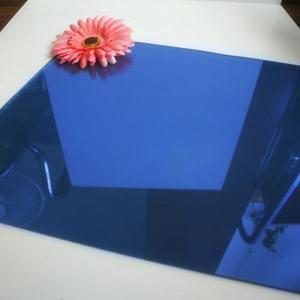

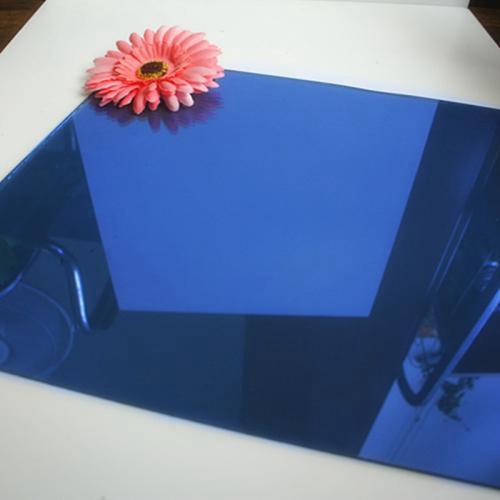

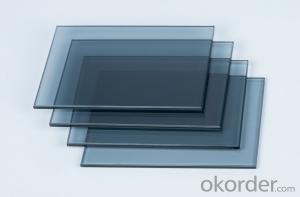

Tinted Float Glass Ford Blue Customized Sizes for Construction and Decoration

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

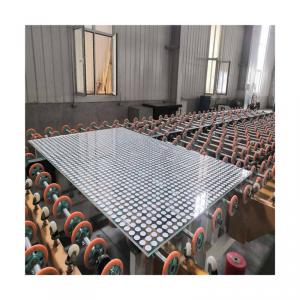

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

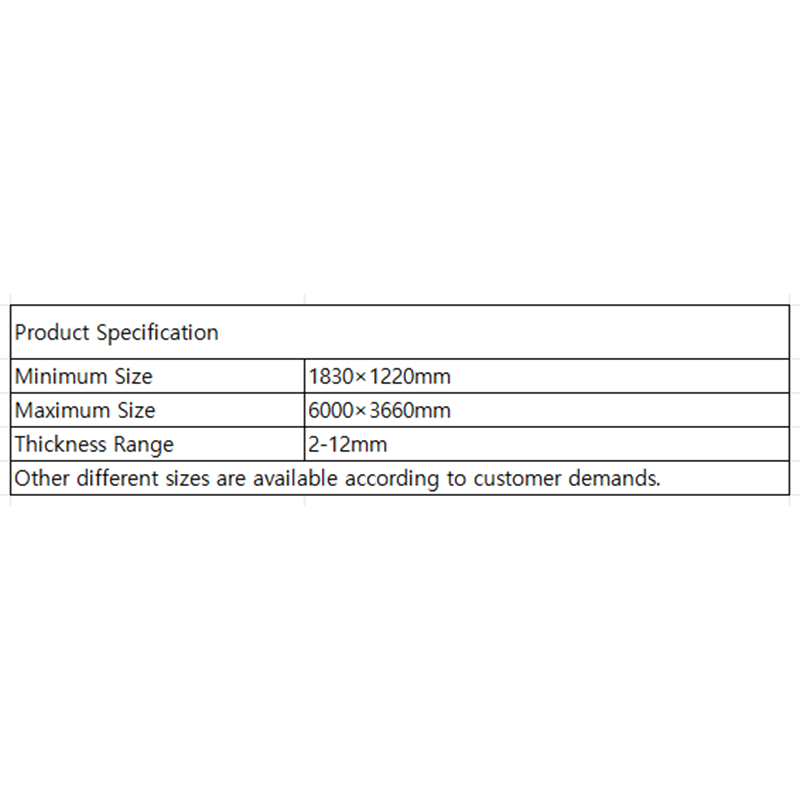

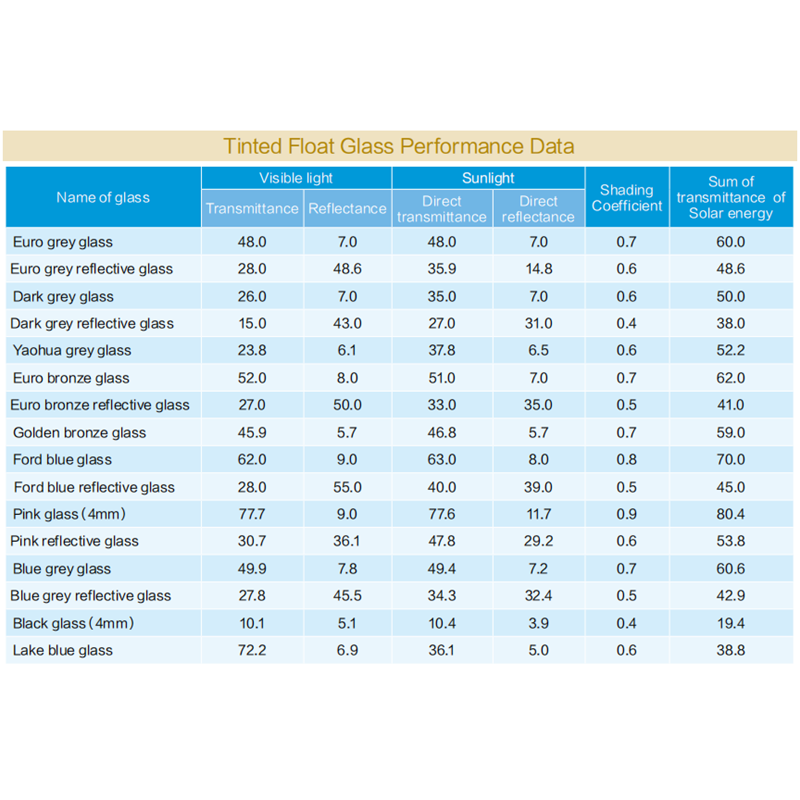

Tinted Float Glass is applicate in construction and decoration.Usually sized 2100x1500mm to 3660x2740mm and 1.6-12mm in thickness and other customized sizes are also available.Customized size make product available in different scenarios.Ford blue color is bright and benifit in aesthetic and keep the balance between transmittance and reflectance.

- Q: What is the difference between the span on the architectural glass and the width of the glass?

- Width, refers to the size of a single piece of glass, that is, between the size of the two sides of the box

- Q: The state is the number of buildings above the tempered glass

- 7 floors and 7 floors above the building outside the window;

- Q: Automotive glass insulation film paste technology

- The most basic tools are roasted guns, watering cans, foil special agent (or detergent water), water scraper, paste scraper, deerskin, Huju, a knife, each model is not the same paste method is not the same , But there is a common point of glass must be cleaned, preferably in the clean film between the operation.

- Q: What is the coating of the glass coating?

- A lot of brand products such as turtle Dr. Anfu car wash the king of the car eagle card like waxing the same process

- Q: Building glass foil company which is good?

- The constant film industry's glass film products cover high and low grades, regardless of customer's unique needs for insulation, safety, light transmission, privacy, price, etc., which can be met in the constant megasonic industry Architectural glass foil: thermal sunscreen, energy saving, safe explosion-proof, anti-ultraviolet, anti-glare glare, easy to create a private space, enhance visual effects. Our company also has a strict training by the manufacturers of professional paste team, can be attached to the plane, surface and spherical glass, glass doors and windows can be contracted, glass curtain wall, glass roof and other structures of the glass insulation energy-saving projects.

- Q: The Louvre pyramid in Paris, France, is built of glass panes. There are 4 panes in the top row, and each additional row has 4 more panes than the previous row. 1.Write a series in summation notation to describe the total number of glass panes in n rows of the pyramid. 2.If the pyramid were made of 18 complete rows, how many panes would it have? 3.The actual pyramid has 11 panes less than a complet 18-row pyramid because of the space for the entrance. Find the total number of panes in the Louvre pyramid.

- So the first row has 4 panes, the second 8, the third 12, and so on. The nth row would have 4n panes. 1. The total number of glass panes in n rows is 4*1 + 4*2 + 4*3 + ... + 4n or, in summation notation: n ∑ 4i i=1 2. n=18 4*1 + 4*2 + 4*3 + ... + 4*18 = 4 (1+2+3+ ... + 18) = 4 * 18 * 19 / 2 [using the well-known formula for triangular numbers*] = 36*19 = 684 * T(n) = n(n+1)/2 3. 684-11 = 673

- Q: GB / T16589 instead of which specification

- GB / T 28887-2017 Plastic window for construction is the first edition, so there is no substitute for other older versions. The specification refers to: GB / T 2680-1994 Building glass visible light transmittance, direct sunlight transmittance, solar total transmittance, UV transmittance and the determination of the relevant window parameters, GB / T 5823-2008 Building doors and windows terms, GB / T 7106-2008 Building exterior window windows airtight, watertight, wind pressure performance classification and testing methods, GB / T 8484-2008 building outside doors and windows insulation performance classification and testing methods, GB / T 8485-2008 building windows and doors air sound insulation (PVC-U) profiles, GB / T 11793-2008 Non-plasticized polyvinyl chloride (PVC-U) plastic doors and windows, mechanical properties, GB / T, And GB / T 11976-2002 GB / T 14436-1993 General rules for industrial product assurance documents, GB 50009 - 2001 (2006) JGJ / T 151-2008 Technical code for the application of architectural glass, JGJ / T 151-2008 Code for thermal calculation of glass curtain wall for building windows and doors, GB Building doors and windows.

- Q: Like one big glass enclosement over a farm. It would allow light through, stop excessive rain and bugs from destroying food. They can control the amount of water the plants get. They would save millions

- You have a very narrow scope in thinking about this issue. It wouldn't save millions. The construction of a giant glass dome over a farm would cost a lot in itself. On top of that, consider the maintenance- the glass would need cleaning and would need to be scraped of debris and dead bugs and such over time, like a windshield. Plus the irrigation and sprinkler system that would need to be in place to regulate the watering of the crops would be expensive as well. The heat would be stifling. It would change the very climate within the dome. Climate is very important to the growing of crops. You can't just change the climate of an area and expect the crops to grow better. Just think of how hot it gets when you shut off the car and sit in there for 10 minutes while the heat builds. Who can work under those conditions? Or do you mean to spend money on an elaborate fans system too?

- Q: How much would it cost to build a 15 foot glass wall that is 1 inch thick and 8 feet in heigh

- I suggest you contact your local glass merchant. I am not being rude but you need more than dimensions to give you an answer. 1, First where do you live. The price in New York is likely to be different than the price in Juneau, Alaska (or in Chiang Mai Thailand where I live!) 2. Do you need a single piece of glass or a lot of smaller panes 3. What specifications for any joints? 4. Do you want the price of construction included or will you do it yourself? 5. Do you want the materials delivered or will you pick them up. 6. What about cost of transport / shipment? I hope you understand what I am getting at. There are too many factors for anyone on here to be able to help you. Therefore contact a local glass dealer and give him/her your EXACT requiremernts and they will give you the only meaningful answer that you will get.

- Q: Will the curtain wall hollow glass which is better?

- Not the best only better. With my personal view: the glass glass flatness and corners to deal with some, but some of your skin flatness of the epithelium is also OK, but the corners are better than the South Glass is good. Of course, there are some small manufacturers around, small manufacturers of glass flatness as a whole, especially after the glass of steel.

Send your message to us

Tinted Float Glass Ford Blue Customized Sizes for Construction and Decoration

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches