Tinplate of First Class Level for Making Crown Corks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tinplate of First Class Level for Making Crown Corks

1.Structure of Description

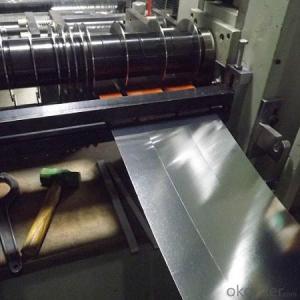

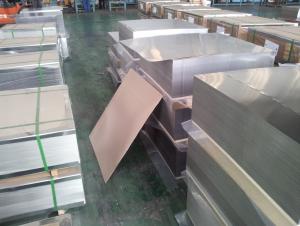

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Specifications

| Type | MR, SPCC |

| Temper(BA&CA) | T1-T5, DR8-DR10 |

| Coating | 1.1-8.4g/m^2 |

| Thickness& Tolerance | 0.15-0.5mm(tolerance +/-0.01mm) |

| Width& Tolerance | 600-1010mm(tolerance +2/-0mm) |

| I.D | 508mm |

| Coil weight | 3-10MT |

| Passivation | 311 |

| Oiling | DOS |

| Surface finish | Bright, stone |

| Package | Seaworthy Export Standard Wooden Pallet |

| Standard | ISO 11949 -1995, JIS G3303,ASTM A623, BS EN 10202 |

| Special specifications are available on customers' requirements | |

Application

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

- Chemicals and painting cans

- Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans,

- Sea food cans

- Crown corks, easy open ends

- Electrical machinery parts

- Bakeware and household kitchen parts

FAQ

CNBM Branch Offices

In order to promote the business connection, CNBM has established branches and offices in lots of foreign countries, such as USA, GERMANY, UAE, SAUDI ARABIA, IRAN, JORDAN, LIBIA,ETHIOPIA, INDONESA, INDIA,VIETNAM,RUSSIA,KAZAKHSTAN. It is very helpful for the communication and after- sale services.

Factory Introduction

China National Building Materials Group Cooperation, as a leading state-owned enterprise with 3 billion USD and 40,000 staff in China, CNBM was established in 1984 under the administration of the state-owned Assets Supervision and Administration commission of the State Council. There are over 300 surbordinate factories and companies in our group; 2 public listed companies in Hong Kong, 4 Public listed companies in China mainland; 11 publicly listed companies in which CNBM has a substantial percentage of shares. The business scope of CNBM covers from Manufacturing and sales of building materials to scientific research and design, engineering, import and export trading.

On July 7th, 2011, Fortune Magazine established Fortune Global 500 ranking on its website, and CNBM Group was listed for the first time, with a ranking of 485.

- Q: What are the environmental impacts of tinplate production?

- The production of tinplate has several significant environmental impacts. Firstly, the extraction of tin from its ore requires extensive mining operations, which can result in habitat destruction, soil erosion, and water pollution. Additionally, the smelting process releases various air pollutants, including sulfur dioxide and particulate matter, contributing to air pollution and potentially causing respiratory issues. Furthermore, the tin coating process involves the use of chemicals, such as acids and solvents, which can lead to water contamination if not properly managed. Lastly, the disposal of tinplate waste, including scrap and byproducts, can pose challenges in terms of proper handling and recycling, potentially leading to landfill accumulation. Overall, the environmental impacts of tinplate production underline the importance of adopting sustainable practices and promoting circular economy principles in this industry.

- Q: Is tinplate resistant to scratches and dents?

- Yes, tinplate is resistant to scratches and dents.

- Q: What are the common sizes of tinplate sheets?

- The common sizes of tinplate sheets typically range from 0.15mm to 0.5mm in thickness, and can vary in width from 600mm to 1200mm.

- Q: What are the advantages of tin packaging?

- Mature technology and high production efficiency: the production of tinplate has a long history, has a mature skill set of production equipment with matching, high production efficiency, can meet a variety of product packaging needs.

- Q: How is tinplate coated for chemical storage containers?

- Tinplate is typically coated for chemical storage containers using a process called electrolytic tin plating, where a layer of tin is electrochemically deposited onto the surface of the steel substrate. This tin coating helps to protect the container from corrosion and chemical reactions, ensuring safe storage and transportation of chemicals.

- Q: What is the average lifespan of tinplate packaging?

- The average lifespan of tinplate packaging depends on various factors such as usage, storage conditions, and handling. However, tinplate packaging is known for its durability and longevity, and with proper care, it can last for several years or even decades.

- Q: Is tinplate suitable for hot or cold food products?

- Tinplate is suitable for both hot and cold food products.

- Q: What are the main trends in tinplate packaging design?

- The main trends in tinplate packaging design include minimalistic and clean designs, eco-friendly and sustainable packaging solutions, innovative and functional packaging designs, and the use of vibrant colors and bold graphics to attract consumers' attention.

- Q: How does tinplate perform in terms of magnetic properties?

- Tinplate has poor magnetic properties, as it is not a magnetic material.

- Q: What are the main challenges in the tinplate industry?

- The main challenges in the tinplate industry include fluctuating prices of raw materials, increasing competition from alternative packaging materials, stringent environmental regulations, and the need for continuous technological advancements to improve production processes and meet changing customer demands. Additionally, the industry also faces challenges related to supply chain management, ensuring product quality and safety, and navigating global trade dynamics.

Send your message to us

Tinplate of First Class Level for Making Crown Corks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords