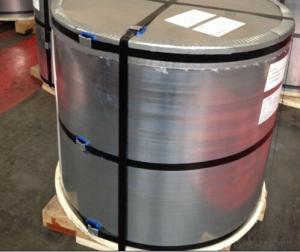

tinplate from thickness 0.21 to 0.25mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are one of the main producers in Chinafor tinplate. At present, ourproductivity is about 450000 MT/year. Tinplate size:

TEMPER: T1-T5, DR7-9

ANNEALING:BA/ CA

THICKNESS: 0.15~0.45mm

WIDTH: 600~1050mm

The main product tinplate and tin freesteel are metal package material widely used in food, light industry andchemical industry. We organize our production strictly in accordance with Q/ZYBE1、Q/ZYB E3、GB/T252, GB/T24180, JIS G3303, JIS G3315 and ISO11950 or equivalentstandards. Companies adhere to principles of quality, food safety, environment,occupation, health safety and energy, say "excellent quality to win thetrust of customers, health and safety to gain the trust of the public, cleanenvironment to harvest the trust of the community, safety and health toconvince employees and energy-saving to be trusted by public". We areenjoying the trust and good name regarding to the superior quality and preferservice among the customers. Our products are sold nearly 150 enterprisesincluding Europe, America, Oceania, Middle East and Southeast Asia.

Company management system is healthy, operational mechanism runninggood. After years of effort, base on the introduction, absorption, digestion ofthe advanced technology, techniques, equipment, we gradually set up the uniqueproduction process and technical support system which is market need-orientaland suite to the Chinese condition. In the fierce market competition, ourcompany will continue to pursue the excellence quality and outstanding service,and provide more and better service and service to meet customers demand onmetal package home and abroad.

We has a customer service center whichproviding customers with whole-process service including the pre-sale, sale andafter-service, unified handling customer inquiries and complaints. CustomerService Center adhere to the goal “customer first and response rapidly” andarrange their service work according to the standard procedures. Ourcommitment: ready to accept advice and customer complaints, reply commentswithin 24 hours of treatment, when dealing with customer complaints of qualityissues, upon customer’s request, sent the inspector to the user site to saveproblem within 24 hours (within the province) and 48 hours (other provinces).

- Q: Can tinplate be used for bakery packaging?

- Yes, tinplate can be used for bakery packaging. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent protection against moisture and oxygen. It is commonly used in the food industry, including bakery packaging, as it helps preserve the freshness and quality of baked goods. Additionally, tinplate is durable, recyclable, and has good heat resistance, making it suitable for bakery packaging requirements.

- Q: What are the main regulations governing tinplate production?

- The main regulations governing tinplate production include health and safety standards, environmental regulations, quality control measures, and labeling requirements. These regulations ensure that tinplate production processes are conducted safely, with minimal impact on the environment, and that the final product meets quality standards. Additionally, labeling requirements ensure that tinplate products are accurately labeled and provide necessary information to consumers.

- Q: What are the common storage and handling requirements for tinplate?

- The common storage and handling requirements for tinplate include keeping it in a clean and dry environment to prevent rusting or corrosion. It should be stored in a well-ventilated area away from direct sunlight and sources of heat. Tinplate should be handled with care to avoid any sharp impacts or bending, as it can affect its structural integrity. It is also important to stack tinplate properly, ensuring that there is no excessive weight on top of it to prevent deformation. Regular inspection and maintenance are necessary to detect any signs of damage or corrosion early on.

- Q: Can tinplate be used for packaging industrial products?

- Yes, tinplate can be used for packaging industrial products. Tinplate is a type of steel coated with a thin layer of tin, which makes it highly resistant to corrosion and provides a protective barrier for the packaged products. It is commonly used for packaging industrial products such as chemicals, paints, oils, and other materials that require a durable and secure packaging solution.

- Q: What are the chemical resistance properties of tinplate?

- Tinplate exhibits excellent chemical resistance properties, making it highly resistant to corrosion and oxidation. It can withstand exposure to various chemicals, acids, and alkalis without deteriorating or reacting with them, making it a preferred choice for packaging and coating applications in the food and beverage industry.

- Q: How is tinplate coated with organic coatings?

- Tinplate is coated with organic coatings through a process called electrolytic deposition. This involves immersing the tinplate in an electrolyte solution and passing an electric current through it. The organic coating materials, typically polymers or resins, are dissolved in the electrolyte solution and are attracted to the charged surface of the tinplate. As the electric current passes through, the organic coating materials are deposited onto the tinplate, forming a protective layer.

- Q: What are the typical finishing options for tinplate products?

- The typical finishing options for tinplate products include printing, embossing, lacquering, and coating.

- Q: What are the main applications of tinplate in the chemical industry?

- Tinplate is widely used in the chemical industry for various applications such as packaging, storage, and transportation of chemicals. Its corrosion resistance properties make it an ideal choice for containers, cans, and drums used to store chemicals. Tinplate also provides a barrier against moisture and oxygen, which helps in preserving the quality and integrity of chemical products. Additionally, tinplate is used for the production of aerosol cans, chemical spray bottles, and other packaging solutions, ensuring safe and efficient handling of chemicals in the industry.

- Q: How is tinplate price determined?

- The price of tinplate is determined by various factors including the cost of raw materials, market demand and supply, production and manufacturing costs, as well as any additional taxes or tariffs imposed on the product. Additionally, global economic conditions, exchange rates, and competition within the industry can also influence the pricing of tinplate.

- Q: Can tinplate be easily opened and resealed?

- No, tinplate cannot be easily opened and resealed as it typically requires specialized tools or equipment to open and seal it properly.

Send your message to us

tinplate from thickness 0.21 to 0.25mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords