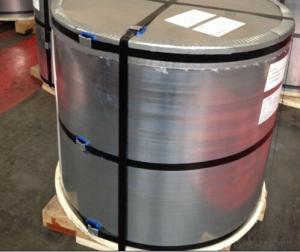

ETP thickness from 0.35 to 0.40

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are one of the main producers in Chinafor tinplate. At present, ourproductivity is about 450000 MT/year. Tinplate size:

TEMPER: T1-T5, DR7-9

ANNEALING:BA/ CA

THICKNESS: 0.15~0.45mm

WIDTH: 600~1050mm

The main product tinplate and tin freesteel are metal package material widely used in food, light industry andchemical industry. We organize our production strictly in accordance with Q/ZYBE1、Q/ZYB E3、GB/T252, GB/T24180, JIS G3303, JIS G3315 and ISO11950 or equivalentstandards. Companies adhere to principles of quality, food safety, environment,occupation, health safety and energy, say "excellent quality to win thetrust of customers, health and safety to gain the trust of the public, cleanenvironment to harvest the trust of the community, safety and health toconvince employees and energy-saving to be trusted by public". We areenjoying the trust and good name regarding to the superior quality and preferservice among the customers. Our products are sold nearly 150 enterprisesincluding Europe, America, Oceania, Middle East and Southeast Asia.

Company management system is healthy, operational mechanism runninggood. After years of effort, base on the introduction, absorption, digestion ofthe advanced technology, techniques, equipment, we gradually set up the uniqueproduction process and technical support system which is market need-orientaland suite to the Chinese condition. In the fierce market competition, ourcompany will continue to pursue the excellence quality and outstanding service,and provide more and better service and service to meet customers demand onmetal package home and abroad.

We has a customer service center whichproviding customers with whole-process service including the pre-sale, sale andafter-service, unified handling customer inquiries and complaints. CustomerService Center adhere to the goal “customer first and response rapidly” andarrange their service work according to the standard procedures. Ourcommitment: ready to accept advice and customer complaints, reply commentswithin 24 hours of treatment, when dealing with customer complaints of qualityissues, upon customer’s request, sent the inspector to the user site to saveproblem within 24 hours (within the province) and 48 hours (other provinces).

- Q: What are the different ways to open tinplate cans?

- There are a few different ways to open tinplate cans. The most common method is using a can opener, either a manual one or an electric one. Another way is by using a knife or a pair of scissors to puncture and cut open the lid. Some cans also have pull-tab lids that can be easily opened by pulling the tab upwards. Lastly, there are specialized tools like a claw hammer or a multi-tool that have a prying function to open cans.

- Q: What are the main innovations in tinplate manufacturing?

- Some of the main innovations in tinplate manufacturing include the introduction of continuous annealing processes, advancements in tin coating technology, improved quality control systems, and the use of automated production lines. These innovations have led to increased efficiency, higher quality tinplate products, and reduced environmental impact in the manufacturing process.

- Q: How is tinplate tested for corrosion resistance?

- Tinplate is typically tested for corrosion resistance through various methods such as salt spray testing, electrochemical impedance spectroscopy, and visual inspection. These tests help assess the durability of the tin coating and its ability to protect the underlying metal from corrosion in different environments.

- Q: What are the advantages of using tinplate for paint cans?

- There are several advantages of using tinplate for paint cans. Firstly, tinplate is highly resistant to corrosion, ensuring that the paint cans remain durable and do not rust over time. Secondly, tinplate has excellent sealing properties, preventing any leakage or evaporation of the paint. Additionally, tinplate is lightweight and easy to handle, making it convenient for transportation and storage. Lastly, tinplate is a sustainable choice as it is recyclable, contributing to environmental conservation efforts.

- Q: What are the common sealing options for tinplate containers?

- The common sealing options for tinplate containers include twist-off caps, peelable lids, press-on lids, and vacuum-sealed lids.

- Q: What are the characteristics of different tin process

- Good mechanical properties: tinplate cans relative to other containers, such as plastic, glass, paper containers and strength, and good rigidity, it is not easy to break. It is not only used for small sale packing, but also the main container for large transportation package. 2.: excellent barrier tin barrier properties than any other materials are excellent, gas barrier properties, moisture resistance, shading and aroma were good, and the sealing is reliable, reliable protection products.

- Q: How is tinplate cut and formed into different shapes?

- Tinplate is commonly cut and formed into different shapes using a variety of methods such as shearing, blanking, stamping, and deep drawing. These processes involve using specialized machinery and tools to cut the tinplate into desired shapes or form it into specific structures.

- Q: Can tinplate be used for packaging pet care products?

- Yes, tinplate can be used for packaging pet care products. Tinplate is a durable and food-safe material that can effectively protect and preserve various products, including pet care items, such as pet food, treats, and grooming products. Additionally, tinplate packaging offers excellent resistance to corrosion and can be easily shaped and decorated to enhance product appeal.

- Q: What are the main applications of tinplate in the energy industry?

- Tinplate is widely used in the energy industry for various applications such as manufacturing of batteries, fuel cells, and solar panels. It provides corrosion resistance and ensures the durability of these energy storage and conversion devices. Additionally, tinplate is used in the construction of transformer cores, which are crucial components in electrical power systems.

- Q: What are the benefits of using tinplate for roofing?

- Tinplate offers several benefits for roofing, including its durability, resistance to corrosion, lightweight nature, and ease of installation. It provides excellent protection against harsh weather conditions and can withstand extreme temperatures. Additionally, tinplate roofs have a long lifespan, require minimal maintenance, and are environmentally friendly as they can be recycled.

Send your message to us

ETP thickness from 0.35 to 0.40

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords