Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness Description

Also known as chromed steel, tin-free steel (TFS) is obtained by coating the metal base (low-carbon steel) with an ultra-thin layer of metallic chrome and then with a chromium oxide layer.

The product complies with ASTM A-657 Specification and is manufactured with low current density (TFS-III) and is supplied in coils (up to 12 metric tons)or sheets.

2.Main Features of the Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness

Appearance – Tinplate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Formability and strength – Tinplates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Solderability and weldability – Tinplates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

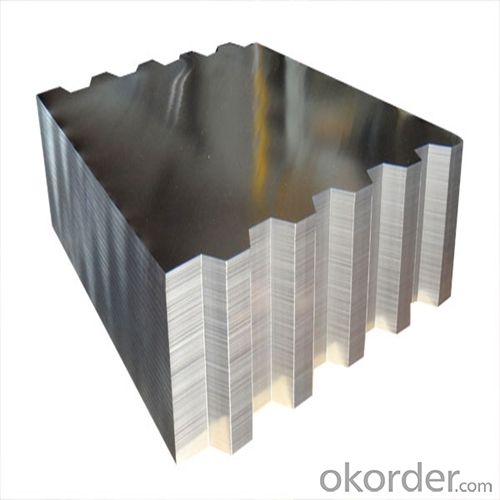

3.Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness Images

4.Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: What are the typical finishing options for tinplate products?

- The typical finishing options for tinplate products include printing, embossing, lacquering, and coating.

- Q: How does tinplate affect the overall product visibility?

- Tinplate can significantly enhance the overall product visibility due to its shiny and reflective surface. It adds a premium and attractive appearance to the product packaging, catching the attention of consumers. Additionally, tinplate allows for high-quality printing, enabling detailed and vibrant graphics that further enhance product visibility on store shelves.

- Q: What is the cost of tinplate?

- The cost of tinplate varies depending on factors such as the current market conditions, quality of the tinplate, and the quantity being purchased. It is recommended to check with suppliers or conduct market research for the most accurate and up-to-date pricing information.

- Q: How is tinplate used in the manufacturing of kitchenware?

- Tinplate is commonly used in the manufacturing of kitchenware due to its unique properties. It provides a protective coating that prevents corrosion and enhances the durability of the kitchenware items. Tinplate is often used to create food cans, utensils, and other cookware. Its ability to resist corrosion and maintain food quality makes it a popular choice for kitchenware manufacturers.

- Q: What are the advantages of using tinplate for construction materials?

- One of the main advantages of using tinplate for construction materials is its exceptional durability and corrosion resistance. Tinplate is a steel sheet coated with a thin layer of tin, which provides a protective barrier against rust and other forms of corrosion. This makes it ideal for construction applications where exposure to moisture or extreme weather conditions is a concern. Additionally, tinplate is lightweight and easy to work with, allowing for efficient installation and reducing the overall weight of the structure. Its aesthetic appeal, versatility, and recyclability are also notable advantages that make tinplate a preferred choice for various construction needs.

- Q: How does tinplate perform in terms of magnetic properties?

- Tinplate has poor magnetic properties, as it is not a magnetic material.

- Q: What are the advantages of using tinplate for beverage cans?

- Tinplate offers several advantages for beverage cans, including its excellent resistance to corrosion, its ability to maintain the freshness and taste of the beverage, its high strength-to-weight ratio, its ease of recyclability, and its cost-effectiveness.

- Q: Can tinplate be used for packaging products with sensitive electronic components?

- No, tinplate cannot be used for packaging products with sensitive electronic components as it can cause electromagnetic interference and potentially damage the components.

- Q: What are the common surface coatings for tinplate?

- The common surface coatings for tinplate include lacquer, enamel, organic coatings, and tin-free steel coatings.

- Q: What are the main challenges in the production of tinplate?

- Some of the main challenges in the production of tinplate include sourcing high-quality tin and steel materials, ensuring proper adhesion of tin coating to the steel substrate, maintaining consistent tin coating thickness, preventing surface defects such as tin whiskers or blisters, and meeting environmental regulations related to waste disposal and emissions.

Send your message to us

Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords