Prime Quality Tinplate for MR Steel With 0.26mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

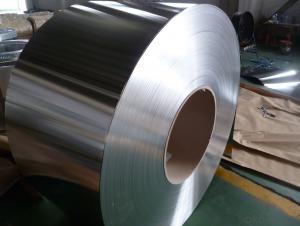

Prime Quality Tinplate for MR Steel With 0.26mm

1.Structure of Description

Prime Quality Tinplate for MR Steel With 0.26mmis one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

For 0.26 tinplate sheet, there are many customers used for produce food cans or edibil oil cans, if you have some same request, pls contact.

3. Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.31

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

D. Can it make to be BA or CA for annealing?

Yes, both can do with.

- Q: How is tinplate used in the manufacturing of electronic devices?

- Tinplate is commonly used in the manufacturing of electronic devices for its corrosion resistance and excellent conductivity. It is often utilized as a coating material for printed circuit boards (PCBs) to protect them from oxidation and enhance their durability. Additionally, tinplate is utilized in the production of connectors, switches, and other electrical components due to its ability to facilitate smooth electrical flow and ensure reliable performance.

- Q: What are the common sizes and thicknesses of tinplate?

- The common sizes of tinplate range from 0.14mm to 0.60mm in thickness, with typical widths varying from 600mm to 1200mm.

- Q: How does tinplate contribute to the safety and integrity of packaged products?

- Tinplate contributes to the safety and integrity of packaged products by providing a protective barrier against external factors such as moisture, light, and oxygen. This helps to prevent the deterioration and contamination of the packaged goods, ensuring their quality and extending their shelf life. Additionally, tinplate is a durable and sturdy material that offers excellent resistance to impact and mechanical damage, safeguarding the contents during transportation and handling.

- Q: What are the main applications of tinplate in the cosmetics industry?

- Tinplate is widely used in the cosmetics industry for packaging various products such as lip balms, creams, powders, and even aerosol cans. Its corrosion resistance, durability, and ability to maintain product integrity make it an ideal choice for ensuring the quality and longevity of cosmetic products. Additionally, tinplate's versatility allows for attractive and customizable designs, enhancing the visual appeal of cosmetic packaging.

- Q: How is tinplate stored and handled?

- Tinplate is typically stored in a dry and clean environment to prevent corrosion. It is important to handle tinplate with care to avoid scratching or damaging the surface. Proper stacking and storage procedures are followed to ensure stability and prevent accidents.

- Q: Can tinplate packaging be used for promotional items?

- Yes, tinplate packaging can definitely be used for promotional items. Tinplate packaging is a versatile and customizable option that can be designed to display brand logos, messages, and captivating visuals. It provides a durable and attractive packaging solution that can enhance the perception of the promotional item and leave a lasting impression on recipients.

- Q: How does tinplate packaging affect the shelf life of products?

- Tinplate packaging can significantly contribute to extending the shelf life of products. Tin is a non-reactive and corrosion-resistant material, which prevents the entry of moisture, air, and light, thereby protecting the contents from oxidation and spoilage. This barrier against external factors helps maintain the product's freshness, flavor, and nutritional value for a longer period. Additionally, tinplate packaging is durable and can withstand physical impacts, ensuring the integrity of the product throughout its shelf life.

- Q: How is tinplate coated for chemical storage containers?

- Tinplate is typically coated for chemical storage containers using a process called electrolytic tin plating, where a layer of tin is electrochemically deposited onto the surface of the steel substrate. This tin coating helps to protect the container from corrosion and chemical reactions, ensuring safe storage and transportation of chemicals.

- Q: How is tinplate cleaned and maintained?

- Tinplate is commonly cleaned and maintained by first wiping it with a soft cloth or sponge soaked in warm soapy water. Any stubborn stains can be gently scrubbed with a non-abrasive cleaner or baking soda paste. After cleaning, it is important to thoroughly dry the tinplate to prevent rusting. To maintain its shine, applying a thin coat of food-grade oil or wax can help protect the tinplate from moisture and oxidation.

- Q: What are the common printing methods used on tinplate?

- The common printing methods used on tinplate include lithography, offset printing, and screen printing.

Send your message to us

Prime Quality Tinplate for MR Steel With 0.26mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords