Tinplate Easy Open End Tinplate in Coil and Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Tinplate Easy Open End Tinplate in Coil and Sheet Description

1) MR BASE MATERIALS FROM POSCO/BAOSTEEL

2) END USE:MILK/BEVERAGE CANS

3)Temper: T1- T5,DR7~DR9

Tinplate is sheet steel covered by a layer of tin, widely used in packaging industry and other field.

2. Main Features of the ETP

Tinplate in primarily used for packaging food stuffs and beverages, also used in containers for oils, grease, paints, polishes,chemicals and many other products. Aerosol containers and caps and closures are also made from ETP.

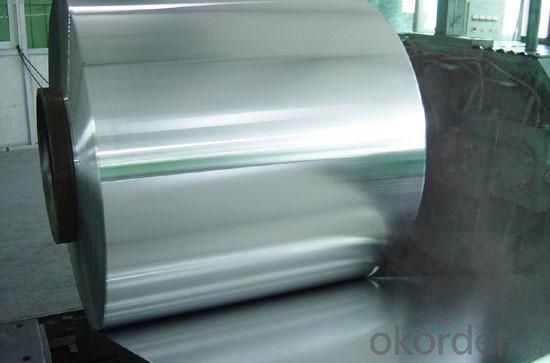

Tinplate is a thin steel coil coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in

corrosion resistance, solderability and weldability. Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging

medium especially for food. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but

is also non-toxic a factor of vital importance in food packaging!

3. Tinplate Easy Open End Tinplate in Coil and Sheet Images

4.Tinplate Easy Open End Tinplate in Coil and Sheet Specification

Product name | Prime T3 Tinplate in sheets |

Steel Type | SPCC, MR |

Temper(BA&CA) | T1~T5 |

Coating for the Prime T3 Tinplate in sheets | 1.1~11.2g/m2 |

Thickness and tolerance | 0.15~0.50mm(Tolerance: _+0.01 mm) |

Width & tolerance | 300~1000mm (Tolerance: 0~3mm) |

Cut length & tolerance | 450~``50mm (Tolerance: 0~3mm ) |

Coil inside diameter | 420/508mm |

Coil Weight | Prime T3 Tinplate in sheets weight 3~10 MT |

Passivation | 311 |

Oiling | DOS |

Surface Finish | Bright, Stone, Silver, Matte |

Packaging | Prime T3 Tinplate in sheets with Seaworthy Standard with wooden pallet |

Standards Available | GB/T2520, JIS G3303, ASTM A623M & EN10202 |

5.FAQ of Tinplate Easy Open End Tinplate in Coil and Sheet

How long does it take to get the product if i place an order?

With the process of your requirements,we will pack and deliver in 3-7 days.If it is by sea shipment,it will take 15-45 days depending on different locations.

- Q: Is tinplate safe for food contact?

- Yes, tinplate is generally considered safe for food contact. It is a commonly used material for food packaging due to its protective properties and ability to resist corrosion, ensuring the safety and quality of the food products stored inside.

- Q: How does tinplate handle exposure to light?

- Tinplate is generally resistant to light exposure and does not undergo significant changes in its properties when exposed to light.

- Q: What are the common thicknesses of tinplate used for different applications?

- The common thicknesses of tinplate used for different applications can vary, but generally range from 0.13mm to 0.49mm. However, specific thickness requirements may depend on the intended use, such as packaging, electronics, or construction.

- Q: How can tinplate be rustproof? Products must not be oil

- It has good salt spray resistance, drainage performance and resistance to hand sweating. It has a long time of rust prevention.

- Q: Can tinplate be used for toys and games?

- Yes, tinplate can definitely be used for toys and games. Tinplate is a durable and versatile material that can be easily molded into various shapes and sizes, making it suitable for manufacturing different types of toys and games. Its corrosion-resistant properties also ensure the longevity of the toys, making it a popular choice in the industry.

- Q: What are the benefits of using tinplate for electrical components?

- Tinplate offers numerous benefits for electrical components. Firstly, it provides excellent corrosion resistance, ensuring the longevity and durability of the components. Secondly, tinplate has excellent solderability, making it easier to connect and assemble electrical circuits. Additionally, tinplate is a good conductor of electricity, allowing for efficient flow of electrical currents. Lastly, it is a cost-effective option, as tinplate is readily available and relatively inexpensive compared to other materials.

- Q: What are the common closure options for tinplate containers?

- Some common closure options for tinplate containers include screw caps, press-on lids, twist-off lids, and pull-tab lids.

- Q: Can tinplate be used for aerosol packaging?

- Yes, tinplate can be used for aerosol packaging.

- Q: Can tinplate be used for packaging chemicals?

- Yes, tinplate can be used for packaging chemicals. Tinplate is known for its excellent corrosion resistance, making it suitable for storing and transporting various chemicals safely. Additionally, its durability and ability to withstand high temperatures make it a reliable choice for chemical packaging applications.

- Q: Can tinplate be used for consumer electronics packaging?

- Yes, tinplate can be used for consumer electronics packaging. Tinplate is a durable and corrosion-resistant material that provides excellent protection for electronic devices. It is commonly used for packaging consumer electronics such as smartphones, tablets, and small appliances.

Send your message to us

Tinplate Easy Open End Tinplate in Coil and Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords