Tinplate Coils / Sheets for Foods Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinplate Coils / Sheets for Food Packaging

Product Description:

Due to Tinplate packaging’s excellent seal, nature, robustness and unique decorative metal charm, it has a wide range of uses in the packaging container industry, and is common in international packaging varieties. With a variety of CC tinplate materials, DR materials, and chrome plated, it is constantly promoted and developed.

Because of its strong antioxidant and diverse styles, beautiful printing, tinplate containers are very popular and loved by customers, and they are widely used in food packaging, pharmaceutical packaging, commodity packaging, instrumentation, packaging, and industrial packaging and much more.

With the continuous improvement of tinplate printing technology and processing technology, tinplate packaging has developed widely.

Product Advantages:

· The salient feature of DR Tinplate is the combination of higher strength and sufficient ductility, which enables much thinner Tinplate to be used, compared to Single Reduced Tinplate resulting in Substantial economic savings.

· According to the steel chemistry and annealing process, the second reduction (DR08) can be between 27% to 40%, thereby producing strengths up to 550 +/-50 N/mm², whereas single reduced material has strength less than 450 N/mm² &DR 09 (Hard DR) is produced at temper mill with reduction % in range of 27-35 % & will strength up to 690 N/mm² to the produced material.

Product Applications:

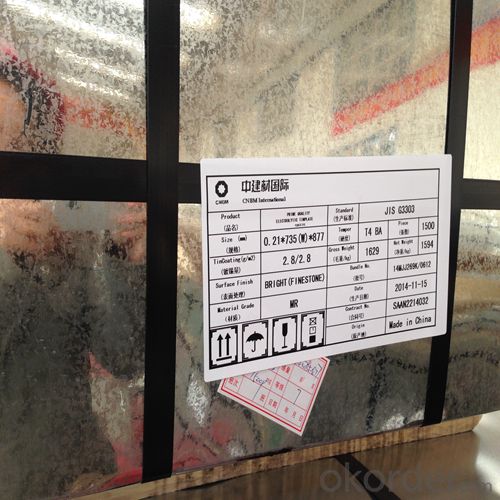

Product Specifications:

Standard | ISO 11949-1995, GB/T2520-2000, JIS G3303, ASTM A623, BS EN 10202 |

Material | MR, SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm - 1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finished, bright, stone, matte, silver |

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: What are the different coating options for tinplate?

- Some of the different coating options for tinplate include electrolytic tin coating, chrome oxide coating, lacquer coating, and organic coatings such as epoxy or polyester.

- Q: How thick is tinplate?

- Tinplate typically has a thickness ranging from 0.13 to 0.49 millimeters.

- Q: What are the key properties of tinplate?

- The key properties of tinplate include its corrosion resistance, durability, malleability, and ability to be easily formed and shaped. Additionally, tinplate has excellent heat resistance, making it suitable for various applications in the packaging industry.

- Q: What are the benefits of using tinplate for pharmaceuticals?

- Tinplate offers several benefits for pharmaceutical packaging. Firstly, it provides excellent protection against light, moisture, and oxygen, ensuring the quality and stability of pharmaceutical products. Secondly, tinplate is a durable and robust material that offers resistance to corrosion, making it suitable for long-term storage. Additionally, tinplate is easily moldable, allowing for various shapes and sizes of packaging, including child-resistant closures. Lastly, tinplate is 100% recyclable, making it an environmentally friendly choice for pharmaceutical companies.

- Q: What are the common packaging formats for tinplate?

- The common packaging formats for tinplate include cans, containers, tins, and boxes.

- Q: Can tinplate be used for packaging frozen food?

- Yes, tinplate can be used for packaging frozen food. Tinplate is a type of steel coated with a thin layer of tin, which provides a protective barrier against moisture, oxygen, and other external factors. This makes it an ideal material for packaging frozen food as it helps to maintain the quality and freshness of the product while preventing freezer burn. Additionally, tinplate is also durable and can withstand low temperatures, making it suitable for freezing and storing food items.

- Q: What are the welding methods used for tinplate?

- The welding methods commonly used for tinplate include spot welding, resistance welding, and laser welding.

- Q: What is the shelf life of tinplate?

- The shelf life of tinplate can vary depending on various factors such as storage conditions and the presence of any protective coatings. However, tinplate typically has a long shelf life, often lasting several years or more if stored properly in a cool, dry place.

- Q: What are the health and safety concerns associated with tinplate?

- Some health and safety concerns associated with tinplate include potential exposure to tin, which can cause respiratory issues and skin irritation if inhaled or in contact with the skin for prolonged periods. Additionally, the coatings used on tinplate may contain harmful chemicals like bisphenol A (BPA), which has been linked to various health problems. It is important to handle and use tinplate products with caution, ensuring adequate ventilation and avoiding direct contact with the coating.

- Q: What are the main applications of tinplate in the sports equipment industry?

- Tinplate is commonly used in the sports equipment industry for various applications such as packaging for tennis balls, protective coatings for golf clubs, and components for hockey sticks. Its corrosion-resistant properties and ability to maintain shape and durability make it an ideal material for ensuring the longevity and performance of sports equipment.

Send your message to us

Tinplate Coils / Sheets for Foods Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords