Tinplate Coil and sheet for making food cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 400000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

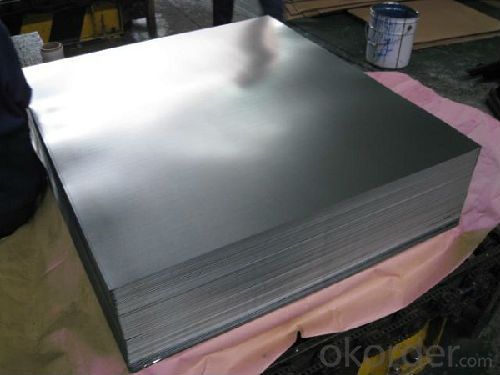

Prime Quality Tinplate Sheets Details

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

Product Specifications:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

- Q: Can tinplate be used for renewable energy applications?

- Yes, tinplate can be used for renewable energy applications. It is commonly used in the production of solar panels, wind turbines, and other renewable energy technologies. Tinplate's high strength and durability make it suitable for protecting and housing sensitive electronic components used in these applications. Additionally, tinplate's corrosion resistance ensures the longevity and performance of renewable energy systems, making it an ideal choice for such purposes.

- Q: What are the common packaging formats for tinplate?

- The common packaging formats for tinplate include cans, containers, tins, and boxes.

- Q: How is tinplate coated for cosmetic packaging?

- Tinplate is typically coated for cosmetic packaging through a process called electrolytic tin plating. This involves immersing the tinplate in a bath containing a tin salt solution and passing an electric current through it. As a result, a layer of tin is deposited onto the surface of the tinplate, providing a protective coating that prevents corrosion and enhances the overall aesthetics of the packaging.

- Q: Can tinplate be used for packaging products with sharp edges?

- Yes, tinplate can be used for packaging products with sharp edges. Tinplate is known for its durability and strength, making it suitable for packaging products that have sharp edges without causing any damage to the packaging material.

- Q: How does tinplate packaging affect the shelf life of products?

- Tinplate packaging can significantly contribute to extending the shelf life of products. Tin is a non-reactive and corrosion-resistant material, which prevents the entry of moisture, air, and light, thereby protecting the contents from oxidation and spoilage. This barrier against external factors helps maintain the product's freshness, flavor, and nutritional value for a longer period. Additionally, tinplate packaging is durable and can withstand physical impacts, ensuring the integrity of the product throughout its shelf life.

- Q: What type of paint is suitable for tinplate?

- Enamel paint is suitable for tinplate due to its durability and ability to adhere to metal surfaces.

- Q: What are the common quality standards for tinplate?

- The common quality standards for tinplate include factors such as the thickness and uniformity of the tin coating, the absence of defects such as rust, scratches, or dents, the overall strength and durability of the tinplate, and compliance with regulatory standards for food safety.

- Q: Can tinplate be used for gift packaging?

- Yes, tinplate can be used for gift packaging. It is a versatile material that offers durability and can be easily shaped into various sizes and designs. Tinplate also provides a visually appealing and premium look, making it an excellent choice for gift packaging.

- Q: What is the difference between food grade tinplate and ordinary chemical tinplate? What is the difference between MR material and SPCC?

- No general food grade and ordinary chemical tinplate tinplate. There are some major is not mature in domestic tin (MR, L, D) the production of tinned steel substrate outside, technology is not mature, not environmental protection, so there is a risk for food cans, can only be used for chemical tank.

- Q: How does tinplate perform in terms of heat transfer?

- Tinplate performs poorly in terms of heat transfer due to its low thermal conductivity.

Send your message to us

Tinplate Coil and sheet for making food cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 400000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords