Tinplate in Sheets and Coils for Cans Packing in good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate in Sheets and Coils for Cans Packing Description

Due to Tinplate packaging`s good seal, nature, dark, robustness and unique decorative metal charm, it has a wide range of coverage in the packaging container industry,and common international packaging varieties. With a variety of CC tinplate material, DR materials, chrome plated and constantly enrich and promotion and development of packaging products and technology, tinplate packaging has promoted with innovation.

Because of its strong antioxidant and diverse styles, beautifully printed, tinplate containers are very popular and loved by customers, and they are widely used in food packaging, pharmaceutical packaging, commodity packaging, instrumentation, packaging, industrial packaging and so on.

With the continuous improvement of tinplate printing technology and processing technology, tinplate packaging has developed more widely.

2.Main Features of the Electrolytic Tinplate in Sheets and Coils for Cans Packing

Appearance – Electrolytic Tin Plate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Electrolytic Tin Plates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Electrolytic Tin Plates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Electrolytic Tin Plates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

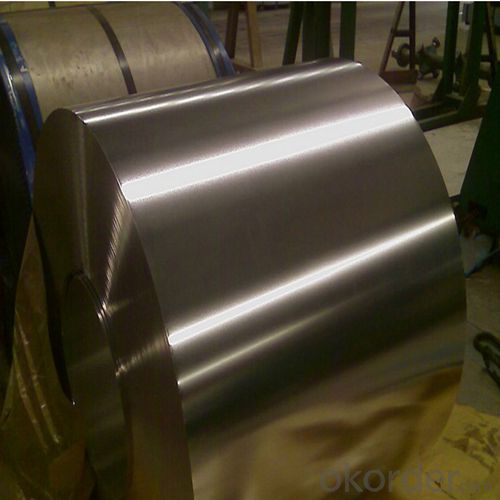

3.Electrolytic Tinplate in Sheets and Coils for Cans Packing Images

4.Electrolytic Tinplate in Sheets and Coils for Cans Packing Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Electrolytic Tinplate in Sheets and Coils for Cans Packing

- How are the Electrolytic Tin Plates specified?

The Electrolytic Tin Plates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: How is tinplate used in the manufacturing of toys?

- Tinplate is commonly used in the manufacturing of toys as it provides a durable and corrosion-resistant material for various toy components. It is often utilized for creating toy packaging, such as colorful tin boxes or cans, which enhance the aesthetic appeal and protect the toys inside. Additionally, tinplate can be used to construct small toy parts, such as wheels or mechanical mechanisms, due to its malleability and ability to retain intricate shapes. Overall, tinplate contributes to the overall quality, longevity, and attractiveness of toys in the manufacturing process.

- Q: How does tinplate compare to plastic packaging?

- Tinplate packaging offers several advantages over plastic packaging. Firstly, tinplate is much more durable and sturdy compared to plastic, providing better protection for the product inside. It is also resistant to temperature changes, making it suitable for storing both hot and cold items. Additionally, tinplate packaging is fully recyclable, making it a more sustainable option compared to plastic which often ends up in landfills. Lastly, tinplate packaging has a premium and aesthetic appeal, making it more appealing to consumers.

- Q: Can tinplate be used for packaging beverages?

- Yes, tinplate can be used for packaging beverages. Tinplate is a durable and corrosion-resistant material that can effectively protect the contents of beverage packaging from external factors such as light, moisture, and oxygen. It is commonly used for packaging canned beverages like soda, beer, and juices.

- Q: How does tinplate packaging contribute to product convenience?

- Tinplate packaging contributes to product convenience by providing a durable and lightweight solution that is easy to handle and store. The tin coating on the packaging helps preserve the product's freshness and protect it from external elements, extending its shelf life. Additionally, tinplate packaging is easy to open and reseal, allowing for effortless access to the product and ensuring its convenience for consumers.

- Q: Can tinplate be used for industrial containers?

- Yes, tinplate can be commonly used for industrial containers due to its strength, durability, and resistance to corrosion.

- Q: Is to buy canned tinplate or aluminum

- Tinplate, our company sells tinplate

- Q: What are the main applications of tinplate in the automotive industry?

- Tinplate is primarily used in the automotive industry for various applications such as fuel tanks, engine covers, battery casings, and other components that require corrosion resistance and durability. It provides protection against rust and enhances the overall aesthetic appeal of these parts.

- Q: How is tinplate coated with food-grade materials?

- Tinplate is coated with food-grade materials through a process called electrolytic tinning. In this process, a thin layer of tin is electroplated onto the surface of the tinplate, creating a protective barrier between the metal and the food. This coating ensures that the tinplate is safe for food contact and prevents any undesirable reactions between the metal and the food.

- Q: What are the main challenges in the recycling of tinplate?

- One of the main challenges in the recycling of tinplate is the separation of tin from the steel. Tin is a valuable material and it is important to recover as much of it as possible during the recycling process. However, separating tin from steel can be a complex and energy-intensive process. Additionally, contaminants such as paints, coatings, and other metals need to be removed before the tinplate can be recycled, which adds to the difficulty of the recycling process. Another challenge is the collection and sorting of tinplate waste, as it often ends up mixed with other materials in municipal waste streams. This makes it necessary to implement effective collection and sorting systems to ensure that tinplate is properly recycled.

- Q: How does tinplate compare to other packaging materials in terms of recyclability?

- Tinplate is highly recyclable and often considered to be one of the most sustainable packaging materials available. It can be easily separated from other materials during the recycling process and has a high recycling rate, making it a preferred choice for environmentally conscious consumers and industries.

Send your message to us

Tinplate in Sheets and Coils for Cans Packing in good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords