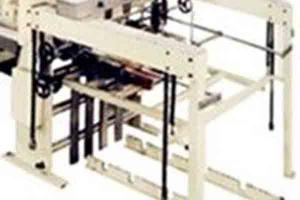

Tin Can Making Line Duplex Gang Slitter Tinplate Sheet Cutting Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Tin Can Making Line Duplex Gang Slitter Tinplate Sheet Cutting Machine Usage and Applications

Type:Packaging Line

Condition:New

Application:Food, Beverage, Chemical, Machinery & Hardware

Packaging Type:Cans

Packaging Material:Metal

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380V

Power:6.95KW

Place of Origin:Zhejiang, China (Mainland)

Certification:CE

After-sales Service Provided:Engineers available to service machinery overseas

Tin Can Making Line Duplex Gang Slitter Tinplate Sheet Cutting Machine Main TechnicalParameters

1.Automatic feeding

2.auto fulfillment of vertical/horizontal cutting,

3.dual-tensioning detection

4.auto counting

| Name | Automatic Gang Slitter |

| Model | GT10A6A |

| Feeding Speed | 0-32 piece/min |

| Cutting Speed | 0-59 m/min |

| Applicable Range | 600-1150 mm |

| Thickness of Tinplate | 0.15-0.5 mm |

| Min Width | 1-6 piece |

| Power | 5.45 KW |

| Weight | 6700 KG |

| Dimension | 6650x3880x1530 |

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping of objects of different shapes according to their appearance.

- Q: What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q: What are the packing machines?

- Heat shrink packaging machine, mask packaging machine, pillow type packaging machine, food packaging machine, I suggest you can go to see

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- (3) large variance, indicating that this group of data volatility, variance is small, volatility is relatively stableAnswer: (1) a = x (501+500+503+506+504+506+500+498+497+495), 10=501,B = x (503+504+502+498+499+501+505+497+502+499), 10=501;(2) S2, =1/n[(501-501) 2+ (500-501) 2+... + (495-501) 2]=12.6,S2 B, =1/n[(503-501) 2+ (504-501) 2+... + (499-501) 2]=6.4;(3) a b > S2 dreams S2,The quality of R B packaging machine 10 bags of sweets is relatively stable.Comments on the subject, mainly on the average number, variance calculation, and their significance, the correct memory formula is the key to solving problems

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of packing equipment, such as food packing, filling, quantitative packing, back channel packing and so on

- Q: What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;Can use blister sealing machine or high frequency plastic welding machine hot pressing;

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- If these are good, and then talk about the price, always a penny goods, this side, quick packaging machine is not bad,

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- 5009.101 determination of antimony in polyester resins and their moulding products for food containers and packaging materialsGB 13113 hygienic standard for polyethylene terephthalate moulding articles for food containers and packaging materials

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- (especially the telephone communication, stop talking no worries) I think you should understand the specific situation, your target customers first, for example: mechanical models currently in use and the time of purchase, production efficiency, what will be improved after the replacement, can recover the cost of even a few years, these are all what you should do in advance homework.

Send your message to us

Tin Can Making Line Duplex Gang Slitter Tinplate Sheet Cutting Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords