Automatic Duplex Slitter Metal Tinplate Sheet Cutting Machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Duplex Slitter Metal Tinplate Sheet Cutting Machine Usage and Applications

1.Product Description:

Type:Packaging Line

Condition:New

Application:Machinery & Hardware

Packaging Type:Cans

Packaging Material:Metal

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380V

Power:5.5KW

Place of Origin:Zhejiang, China (Mainland)

Model Number:GT10A6

Dimension(L*W*H):6650*3880*1530mm

Weight:6700KG

Certification:CE

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

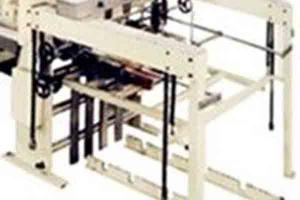

3. Pictures

4. Product Specifications

Automatic Duplex Slitter Metal Tinplate Sheet Cutting Machine Main TechnicalParameters

Name | Automatic Duplex Cutting Machine |

Model | GT10A6 |

Usage | It's used for cutting tinplate / metal sheet into strip or piece materials |

Application Range of Sheet | 600-1250mm |

| Thickness | 0.15-0.5mm |

| Feeding Times | 0-32 times/min ( frequency control ) |

| Cutting Speed | 0-59m/min |

| Power | 5.5KW |

| Dimension | 6650*3880*1530mm |

| Weight | 6700Kg |

5. Applications

It's used for cutting tinplate / metal sheet into strip or piece materials

6. FAQ

Company Introduction.

CNBM is a state- owned enterprise, top 1 in China steel industry, top 500 world wide. More than 180,000 employees and 17 subsidiaries. Total assets of over 50 billion dallors. Wish to be a good friend and long- term business partners.

- Q: What is the design basis of automated packaging?! Just for today!

- 1. each manipulator is controlled by a single computer. A packaging machine for the completion of complex packaging operations, the need to be completed by a number of robot hand. When the package is completed, the information is monitored and controlled by the computer controlled camera, and the manipulator completes the required actions according to the instructions of the computer program to ensure the quality of the packaging.2. high resolution of material and thickness. In the packaging process, the thickness and material change in packaging materials is not easy for the human eye to identify changes in the design of packaging machinery is often used by the computer control of the camera and the detector to identify the thickness of packing material and material. The camera has now been developed to automatically check and identify pictures of the camera and display it on the screen. At present, the machine in the processing speed can not be changed, the future should be based on the change of the material through discrimination can change the speed, so as to control the work in the optimal state, complete the packaging process in the shortest time, and realize the automatic cleaning, automatic sterilization and automatic cleaning

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Sometimes, this wine packaging PigHead, with different types of vacuum packaging machine

- Q: Bread packing machine Product features

- Bread packing machine, also commonly known as pillow type packaging machine. Among them, the suitable packing bread model has CM-320 pillow type packing machine, CM-400 pillow type bread packing machine

- Q: What are the main plastic forming processes?

- The main equipment used for molding compression is to press and mold. The most used hydraulic press is self support hydraulic press. The tonnage varies from tens to hundreds of tons. There is a lower press and an upper press. The die used for compression molding is called pressing die. It is divided into three kinds: overflow mould, half overflow mould, no overflow mold.The main advantage of compression molding is that it can be molded into larger flat products and can be produced in large quantities. Its disadvantage is long production cycle and low efficiency.2. lamination forming. A method of combining two or more layers of material of the same or different material by heating and pressurizing with or without a binder.A layer of floating hot pressing plate is arranged between the movable plate and the fixed plate of the press.The reinforcing materials used in laminated forming are cotton cloth, glass cloth, paper and asbestos cloth. The resins are phenolic, epoxy, unsaturated polyester, and some thermoplastic resins.

- Q: What are the packing machines?

- They make packing equipment. There are many kinds of food packaging, sealing packaging, pillow type packaging machine. I hope I can help you.

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- 10 bags were randomly extracted from each of them, and the actual quality was measured as follows: (unit G)A: 501500503506504506, 500498497495B: 503504502498499501, 505497502499

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of reducers used. What kind of machines are they under?

- Q: Working principle of packing machine

- The working principle of the packing machine is simple. The packing material is first installed on the packing machine and installed

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- There are PLC control ah, if it is fully automatic, then ask the quality of sealing ah, it is best to let manufacturers give you a live demonstration, the soft power depends on the size of the factory, ah, after-sales service ah!

- Q: What's the fastest packing machine?

- Depending on the characteristics of your material, the speed is adjustable!

Send your message to us

Automatic Duplex Slitter Metal Tinplate Sheet Cutting Machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords