Timer Beam FORMWORK SYSTEMS for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

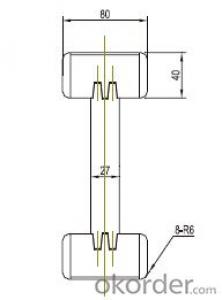

Product name:H20 beam

1. Product description

Flange size | 80mm*40mm*5900mm,or as your request,length up to 10meter |

Web size | 30mm*150mm*5900mm,or as your request,length up to 10meter |

Formaldehyde Emission standards | E0 |

End finish | red plastic wrap, waterproof |

Surface finish | yellow painting, waterproof |

Thickness tolerance | +/-1mm |

Density | 600kgs/cubic meter |

Moisture content | below 12% |

usage | slab formwork system, vertical formwork, adjustable arced formwork, etc. |

Supplying ability | 50000meters/month |

Web thickness | 27mm or 32mm |

Main material | pine |

Glue | WBP(waterproof) |

Delivery time and payment terms |

within 15 days after confirmed the order; T/T with 30% deposit in advance or L/C at sight |

Packing | Packed in pallet, suitable for sea transportation |

2. Production advantage

a.moisture and mold resistant coating

b.LVB(laminated veneer board, cross positioned veneers) and finger-jointed studs ensuring high bending strength

c.vast temperature amplitude durability

d.waterproof 6hours boiling/freezing resistant

e.specially designed rolling mechanism for easy pallet loading and unloading.

f.three layers of paint ,more conducive to waterproof .

g.the wing board is Radiata pine LVL, the web board is poplar plywood, so the product is better stability

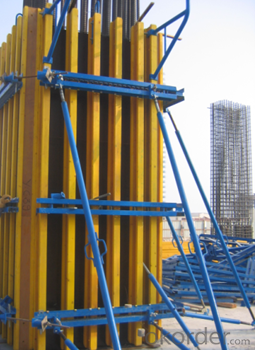

1. Structure of Timber Beam Wall Formwork Description

Timber beam wall formwork is used for the concrete pouring of wall. The application of large areas formwork has greatly increased the construction efficiency and reduced the cost. The system is convenient for construction and it is easy to control the quality. The system has two parts, formwork and pull-push props. The formwork is made of plywood, timber beam and steel waling. Pull-push props can be designed according to the project or simply select the standard props. Tie-yoke and tie-rod are used to reinforce the corner.

2. Main Features of Timber beam wall formworks

-convenient for construction

-easy to control the quality

-easy, rapid and economical.

3. Timber beam wall formwork Images

4. Timber Beam Wall Formwork Specifications

Timber beam column formwork is used for the concrete pouring of square or rectangle column. The system has the same structure and similar connection type with wall formwork.

5.FAQ of Timber Beam Wall Formwork

1) What can we do for you?

.We can ensure the quality of the Timber Beam Wall Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Construction Engineering, moving equipment and stationary equipment, respectively

- Moving equipment refers to the rotating equipment driven by a drive (i.e., equipment with energy consumption), such as pumps, compressors, fans, etc. the energy can be electric power, pneumatic power, steam power and so on. Moving equipment refers to the main components of the movement of machinery, such as various filters, crushers, centrifuges, rotary kiln, mixer, rotary dryer and fluid conveying machinery

- Q: What are the sectors of machine building and parts processing?

- Industry to classify, it is not very strict. For example, the insurance industry, mining, energy, food, hotels, real estate services industry, garment industry, advertising industry, aerospace, aviation, chemical, chemical, construction, health care, education, training, computer, metal smelting, fire, police, soldiers, accounting, beauty, body, media, publishing, wood, paper retail, wholesale, agriculture, tourism, justice, lawyers, sports, sports, arts, entertainment, medical, art, design, banking, finance, Internet, music, dance, postal, courier, transport, consulting services.

- Q: What is the use of spare parts prices in Chinese market by foreign companies?

- You might be gathering information for him. You have no data for one person, if there are several people? They can analyze a lot of things through big data. You can't find out, you're OK. Once you find out, your whole life is over.

- Q: Definition of large mechanical equipment?

- Depending on the size of the part to be machined, the parts must be set up as large equipment with the aid of a crane, and large machinery is usually assembled after the parts have been delivered to the destination. Material handling machinery is mainly in enterprises (including terminals, materials, mines and commercial warehouses, etc.) within the material handling, transportation, lifting, stacking and storage of machinery and equipment

- Q: What are the safety protection equipment, machinery and equipment, construction machinery and accessories for construction enterprises?

- For Turner, fitter, main work gloves, hats, goggles for welder, etc.; there are gloves, shoes cover, goggles, insulated shoes etc.;...... ;

- Q: How do the welding parts in the welding drawings of the machine parts indicate the technical requirements of the drawings?

- With what groove related, open groove is not the same, marking is not the same, "welding structure" reference to our specialized courses

- Q: Where are the mechanical pressurization air supply facilities set up?

- The purpose of setting up a mechanical pressurization air supply smoke prevention system is to provide evacuation routes and shelters without smoke interference in the event of a fire in the building. Therefore, in the closed door, pressing position, and the fire floor must maintain a certain pressure difference, the position of the air pressure value is a relative positive pressure); at the same time, in the open part of the pressure when the door can have enough air velocity in the opening section, to effectively prevent the intrusion of flue gas, the safety of personnel ensure evacuation and refuge.

- Q: What are the world famous mechanical equipment exhibition?

- 1, the German BMW Exhibition (BAUMA) sponsored by: Messe M nchen GmbH, held every three years, has held 30 sessions, the thirty-first will be in April 2016 11-17 in the German city of Munich exhibition centre. The German international engineering machinery, building materials machinery, mining machinery, construction vehicles and Equipment Expo is the world's largest and most influential international engineering machinery, building materials machinery, mining machinery industry exhibition, every three years regularly held in Munich in germany. The fair combines science and technology, trade, information and technical cooperation

- Q: What are the sub projects of a construction project?

- Appendix B Construction Engineering Division (sub branch) engineering, sub project division, B.0.1 Construction Engineering Division (sub branch), engineering, sub projects can be divided into table B.0.1. Table B.0.1 division number of construction works, sub works and sub projects

- Q: What is the difference and connection between equipment manufacturing and machine building?

- In accordance with the standards of classification, including metal products, general machinery manufacturing, machinery manufacturing, transportation equipment manufacturing, electronic and communication equipment manufacturing industry, electrical machinery and equipment manufacturing, instrumentation and office machinery manufacturing seven deducted 186 small consumer related manufacturing industry after class. Equivalent to the European countries referred to as "capital goods manufacturing", that is, we often say "the production of means of production industry."".

Send your message to us

Timer Beam FORMWORK SYSTEMS for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords