TIMBER BEAM CONSTRUCTION FORMWORK SYSTEMS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Timber Beam Wall Formwork Description

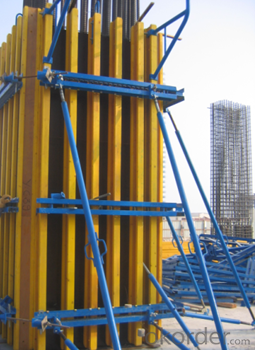

Timber beam wall formwork is used for the concrete pouring of wall. The application of large areas formwork has greatly increased the construction efficiency and reduced the cost. The system is convenient for construction and it is easy to control the quality. The system has two parts, formwork and pull-push props. The formwork is made of plywood, timber beam and steel waling. Pull-push props can be designed according to the project or simply select the standard props. Tie-yoke and tie-rod are used to reinforce the corner.

2. Main Features of Timber beam wall formworks

-convenient for construction

-easy to control the quality

-easy, rapid and economical.

3. Timber beam wall formwork Images

4. Timber Beam Wall Formwork Specifications

Timber beam column formwork is used for the concrete pouring of square or rectangle column. The system has the same structure and similar connection type with wall formwork.

5.FAQ of Timber Beam Wall Formwork

1) What can we do for you?

.We can ensure the quality of the Timber Beam Wall Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

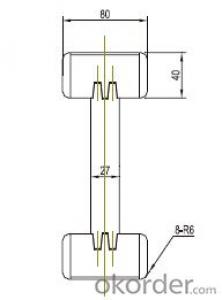

H20 timber beams SPECIFICATION:

1)Materail:New Zealand Radiate Pine

2)Flange: 80*40mm(LVL Structure)

3)Web: 27mm (Plywood or LVB Structure)

4)Weight/: 5.00kg-5.20kg/meter

5)Length avaible:Max 12meter

6)Quality: SGS test report according to EN13377:2002

7)Surface finishing: waterproof yellow painting or other color as the customers request

8)Package:Pallets on the bottom,and Steel band for strength

9)GLUE:WBP/MUF

10)Price advantage: 20-30% cheaper than Austria based on same quality

Product Name | |

Height | 200mm |

Flange | Wide*Thickness=80mm*40mm |

Spruce, Pine, a mixture of wood species permitted | |

Web | Thickness:27-30mm |

3-plywood or plywood | |

Surface Protection | The complete beam is waterproofed using a water-repellent color glaze |

Weight | 4.6-5.2kg |

Standard Lengths | 2.45m,2.65m,2.9m,3.3m,3.6m,3.9m,4.5m,4.9m,5.9m, (Max.length:6.00m) |

Shear Force | q=11KN |

Permissible Bending Moment | m=5.0KN*M |

Package | Customized Package,or In Bulk |

Used for | Slab Formwork System,Vertical Formwork(Wall,Column,Hydraulic Climbing etc.), Adjustable Arced Formwork etc |

H20 Beam/H16 Beam and Film Faced Plywood

H20 beams advantage:

1.With low weight, high rigidity and water proof, timber beam H20 is one of the most important components in the formwork system all over the world. It can be repeated used for many times, which save much cost. 2. Timber beam can be widely used in slab formwork system, vertical formwork (wall, column, hydraulic climbing etc.), adjustable arced formwork etc. 3. Timber beam system is easy to operation and can be assembled in different size and shape of formwork within certain range. The max. pouring height can be over 10 meters. As the lower weight of the materials, the formwork is much lighter than steel formwork. 4. With high standard components, the formwork can be repeated used for many times. 5. The wing board is using dried pine with a percentage of moisture below 13%. The wing board is composed of many pcs of short pine by using special adhesive to avoid the internal shear force. The web board is using plywood. 6. The surface of the timber beam is water proof, acid proof and alkali proof.

- Q: What are the sectors of machine building and parts processing?

- 3., machinery manufacturing is also a kind of industry, many industries have parts manufacturing, processing links. Therefore, the processing of parts does not belong to a particular industry.

- Q: What are the main functions of construction equipment monitoring system?

- This belongs to information management engineering. The control part is the "heart" and "brain" of the whole system. It is the command center to realize the function of the whole system. The control part is mainly composed of the main console (some systems also have a secondary console). The main function of the total console: video signal amplification and signal distribution, image correction and compensation, image signal and image signal (including switching or voice signals) record, cameras and auxiliary components (such as camera, PTZ, shield) control (remote control) and so on.

- Q: What measures can effectively reduce the construction accident rate?

- Hefei construction workers training _ security technology to prevent accidents: prevent the basic starting point of safety accidents is to take measures to restrict energy and dangerous material, to prevent the accidental release. Common safety techniques for preventing accidents are eliminating dangerous sources, limiting energy or dangerous substances, isolating and so on.

- Q: How are the machine parts stacked?

- Then there is a point to note, that is, from there to get used, must be put back where, so that will be organized, all things are owned by you, it will not mess.

- Q: What are the mechanical drawing software?

- The 3D map only contact with SolidWords and Pro/E, Pro/E is better than Solidwords in general, but Solidwords is very simple to use, see Help tutorials you can learn to draw a three-dimensional map is not particularly complex easily to estimate a few days is enough. But any one of the two kinds of software, want to do not understand the words, expert advice is not really easy. UG and MasterCAM haven't touched much, but I've heard that it's suitable for processing stereogram.

- Q: What are the world famous mechanical equipment exhibition?

- 2 、 Las Vegas Construction Machinery Exhibition (Conexpo-Con/Agg) sponsored by the American equipment manufacturers association, the American precast concrete association, the United States sand association. It is the world's second largest construction machinery exhibition after BAUMA. The exhibition, sponsored by the American Association of equipment manufacturers, has been held every three years for nearly a hundred years. The next exhibition will be held on March 2017 7-11. The exhibition is of great size and numerous merchants. It has focused on world famous brands such as Caterpillar, Komatsu, Liebherr and Volvo. It is an important platform for displaying the latest technology, equipment and products in the industry.

- Q: Construction machinery production need to deal with what documents?

- The person in charge of the enterprise, the person in charge of the project, full-time safety management personnel in "safety assessment qualified" column content according to the "three persons" Safety Assessment Certificate (fill in the contents of enterprise work safety management staff should meet the enterprise production safety management, the safety management department staff with the qualification to the total contract for not less than 5, not less than 3 professional contracting labor subcontracting, not less than 1; the construction site should be equipped with full-time safety management personnel according to the project size can be determined, according to the construction area of less than 10 thousand M2 project has at least a part-time staff of more than 10 thousand M2; project 1 - 2 full-time staff; more than 50 thousand M2 large sites, according to different professional safety management group);

- Q: How are buildings, installations and materials divided?

- Provisions on the division of equipment and materials for engineering construction? [answer] the division of equipment and materials in engineering construction is directly related to the reasonable division of investment structure, budget preparation and calculation of construction output value. In order to reasonably determine the project cost, strengthen the investment in the process of construction and management, the equipment and materials in the engineering construction is unclear, especially the universal controversial common problems and put forward the principle of division of fifteen copies of "national unified installation project budget quota" of the equipment and materials are divided, the provinces, autonomous regions and municipalities directly under the central government and the relevant departments of the State Council, the Department should be combined with the local situation, formulate rules for its implementation, and report to the Ministry of construction for the record.

- Q: What is a door rack for a construction site? How high is it generally?

- Door scaffolding has not yet unified design and product standards, the products of different specifications, quality is inconsistent. Not only for construction units to use and management of great difficulties, is not conducive to the promotion of applications, but also to the construction safety risks. Therefore, it is necessary to organize and issue a unified standard for door scaffolding

- Q: What functions should be achieved in mechanical structure design?

- The main features of the mechanical structure design are: (1) it is a set of thinking, drawing and calculation (sometimes necessary experiments) in one of the design process, is involved in machinery design, the most specific, the largest volume of work, in the whole process of mechanical design, an average of about 80% of the time for the structure design plays an important role in the success of mechanical design. (2) the multi solution of mechanical structure design, that is, the mechanical structure that satisfies the same design requirement, is not the only one. (3) the mechanical structure design stage is a very active design link, often needs to cross repeatedly. Therefore, in the design of mechanical structure, it is necessary to understand the basic requirements of the mechanical structure from the whole of the machine

Send your message to us

TIMBER BEAM CONSTRUCTION FORMWORK SYSTEMS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords