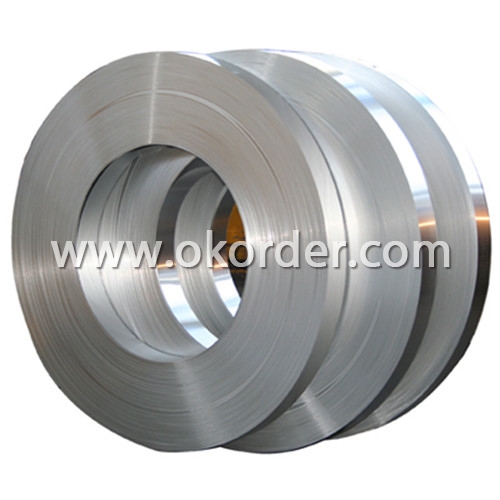

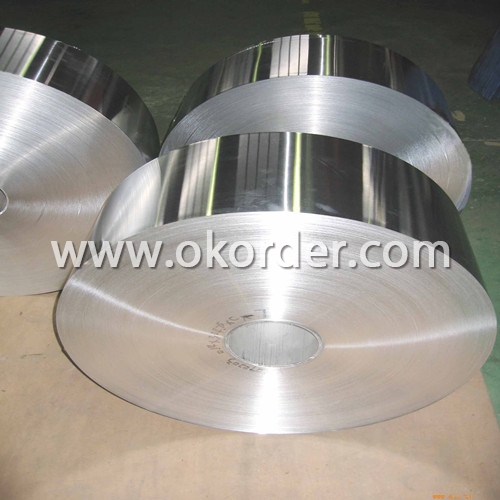

Thin Flat Aluminum Strips AA8006

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Aluminum Strips AA8006

Alloy Number | AA8006 |

Temper | Temper H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness | 0.10-500mm |

Diameter | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

Special specification is available on customers' requirements.

2. Usage/Applications of Aluminum Strips AA8006

Aluminum strips are widely used for PS printed materials substrate, building decoration materials, stamping products, building mirror materials, nameplate, insulation materials, aluminum plastic composite material, capacitor strip, transformer strip, welding parts, heat exchanger, clock surface and disk, kitchen utensils, reflecting apparatus etc.

3. Packaging & Delivery of Aluminum Strips AA8006

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 30 days after getting the buyer's payment.

4. Production Flow of Aluminum Strips AA8006

Rolling--Annealing--Slitting—Sawing, Cut-To-Length, Shearing

- Q: This question asks for a method to measure the thickness of aluminum siding material.

- <p>To determine the thickness of aluminum siding, you can use a digital caliper or a micrometer, which are precise measuring tools. Place the caliper or micrometer at the edge of the siding, ensuring it's perpendicular to the surface, and take a measurement. Another method is to use a magnetic thickness gauge if the siding is coated, as this tool can measure the thickness of non-magnetic coatings on magnetic metals. Always check the manufacturer's specifications for the siding as well, as they often provide thickness information.</p>

- Q: This question asks for a comparison of the benefits and drawbacks associated with the use of aluminum strips.

- <p>Aluminum strips offer several advantages, including high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. They are lightweight, which makes them ideal for applications where weight is a concern, such as in the aerospace and automotive industries. Their resistance to corrosion means they can be used in environments where other metals might rust or degrade. Additionally, their thermal conductivity makes them useful in heat exchangers and other thermal management applications. However, aluminum strips also have disadvantages. They are less rigid than some other metals, which can be a drawback in applications requiring high stiffness. They also have a lower melting point compared to metals like steel, which can limit their use in high-temperature applications. Furthermore, aluminum is a good conductor of electricity, which might be undesirable in certain electrical applications where insulation is needed.</p>

- Q: How does the excavator aluminum belt turn in place?

- This is how it works1. Support the front half of the track with the bucket, so that half or more of the track is out of the ground2, turn the operating lever in the opposite direction of the desired turn, and then turn the track

- Q: Is it possible to substitute metal sheets for asphalt shingles on a roof?

- <p>Yes, you can use metal sheets to replace asphalt shingles on your roof. Metal roofing is a durable and weather-resistant alternative to asphalt shingles. It offers benefits such as longevity, energy efficiency, and low maintenance. However, it's essential to consider the weight of metal sheets compared to shingles, as it may require structural reinforcement. Additionally, proper installation by a professional is crucial to ensure the roof's integrity and to maximize the benefits of metal roofing.</p>

- Q: Is it possible to use aluminum strips for creating decorative accents or wall art?

- <p>Yes, aluminum strips can be used to create decorative accents or wall art. They are lightweight, durable, and come in various colors and finishes, making them a versatile material for crafting. You can bend, cut, and shape aluminum strips into different designs to suit your aesthetic preferences. Additionally, they are easy to install and can be used in combination with other materials to create unique and eye-catching wall art pieces.</p>

- Q: Does aluminum corrode in a manner similar to rusting?

- <p>Aluminum does not rust in the same way as iron or steel. Instead, aluminum reacts with oxygen in the air to form a thin, protective layer of aluminum oxide on its surface. This oxide layer prevents further corrosion, unlike rust which can compromise the integrity of iron and steel. While aluminum can tarnish or become discolored due to exposure to certain elements or chemicals, it does not rust in the traditional sense.</p>

- Q: Describe how the weight of an aluminum strip compares to other common roofing materials.

- <p>An aluminum strip is significantly lighter than many other roofing materials. It weighs approximately 1.5 to 2.5 pounds per square foot, depending on the thickness and profile. In contrast, asphalt shingles can weigh between 2.5 to 4.5 pounds per square foot, while concrete tiles can be as heavy as 7 to 10 pounds per square foot. Clay tiles are also heavier, typically ranging from 6 to 8 pounds per square foot. This makes aluminum strips an attractive option for those seeking a lightweight roofing solution.</p>

- Q: What are the specific types of aluminum strips that are frequently utilized in the construction industry?

- <p>Yes, there are several special types of aluminum strips commonly used in construction. These include aluminum flashing strips for waterproofing and sealing, aluminum trim strips for finishing edges and corners, and aluminum heat sinks for heat dissipation in electrical installations. Additionally, aluminum strips are used in curtain wall systems, window frames, and as reinforcement in concrete structures. The choice of aluminum strip depends on the specific requirements of the construction project, such as strength, durability, and resistance to corrosion.</p>

- Q: This question asks for the distinctions between a roof made from an aluminum strip and a general metal roof. It seeks to understand the specific characteristics that differentiate these two types of roofing materials.

- <p>An aluminum strip roof is a specific type of metal roof, characterized by its lightweight and flexibility. Aluminum strips are often used for their corrosion resistance and durability. They are typically interlocking and can be easily bent to fit various roof shapes. In contrast, a metal roof is a broader category that includes various types of metal materials, such as steel, zinc, or copper, used for roofing. Metal roofs can be made from solid sheets, tiles, or strips, and they offer different levels of weight, durability, and maintenance requirements. While both are long-lasting and resistant to weather, the choice between an aluminum strip roof and other metal roofs often comes down to specific project needs, cost, and aesthetic preferences.</p>

- Q: What are the potential drawbacks or negative aspects of utilizing aluminum strips as a material for exterior siding on a building?

- <p>Aluminum siding, while durable and lightweight, has several disadvantages. It can dent easily due to its softness, which may require frequent repairs. It also lacks insulating properties, leading to increased energy costs as it doesn't retain heat well. Additionally, aluminum siding can be noisy during heavy rain or hail, and it may expand and contract with temperature changes, causing warping or gaps. Furthermore, it can be more expensive than some other materials, and its reflective nature may lead to a less aesthetically pleasing appearance compared to other siding options.</p>

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Thin Flat Aluminum Strips AA8006

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords