TDS Ellipse Uniform-Thickness Vibrating Screen,Vibration Screen

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

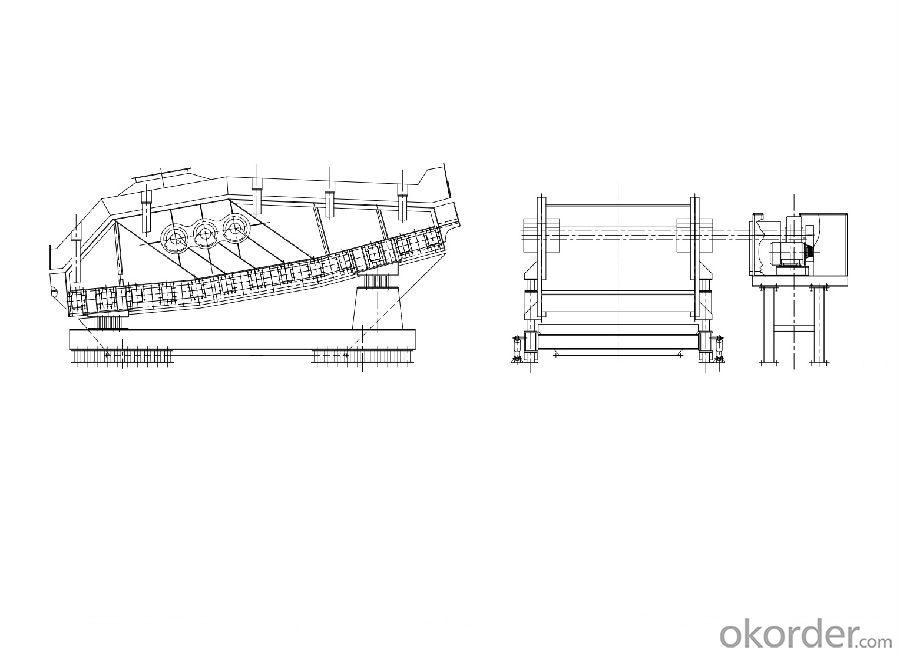

The ellipse uniform-thickness vibrating screen is a kind of vibration screen that it makes a ellipse motion orbit, which has following advantages, such as efficient, high precision of screening and wide applicable and other advantages.

Comparing with the the same specification common screening machine, it has a larger handling capacity and more high-efficiency screening. It is suitable for screening the solvent, sinter in cold condition in metallurgic industry and mineral classification in mine industry, classification, dehydrate and de-medium in mining industry. It is an ideal replaced product to replace present large vibration screen and foreign introduced product.

The ellipse uniform-thickness vibrating screen is mainly made up of straining box, exciter, vibration isolation system, gearing device, deck base with road wheel and other parts. Mostly of the snifter is dual-layer. The structure of the sieve plate is made of cast steel and adopts broach sieve plate. Also, the various sieve plate can be adopted in according to the requirements of the user.

Structural features

It applies the three-phase screen surface design to form the uniform-thickness screening layer.

The materials flow velocity is stable and uniform with high screen efficiency.

It applies three-axis driving and forced synchronous vibration principle to make the stable operation.

There are multiple screen plates for selection.

It is equipped with secondary vibration isolation system to alleviate the foundation load.

The inspection of the screen before the starting:the following items should be inspected.

Firstly, the sanitation should be inspected. Checking all of the connecting bolts to assure whether if they are completed,fastened and intact. Then the exciter should be check to assure that whether if it is intact. Checking the spring vibration aims to assure that whether if there exists no damage, lack, breakage and other phenomenons. Checking the triangular belt aims to assure whether if it is tense and whether if it is in of breakage. Checking the straining box and sieve plate aims to assure whether if it is damaged. Checking the sieve plate aims to assure that whether if it is blocked by the sundries. And the surface of the sifter must be smooth without loose and damaging phenomenon. Checking the inlet and outlet chute aims to assure that whether if it is available. Checking the cross beam aims to assure whether if there exists snap phenomenon. Checking the protective device aims to assure whether if it is reliable and safe. Checking the controlling box, communication and light aim to assure whether if it normal. Checking the ground connection aims to assure that whether if it is reliable and whether if the control buttons are flexible and safe.

Starting: when the vibration screen is started, the operator should stand by the vibration screen to monitor the starting of the machine, which aims to assure whether if there exists abnormal phenomenon. If it does, the machine must be stopped immediately. When the vibration screen is started normally, the operator should patrol all the nozzles on each vibration screen to assure whether whether if it is blocked or it falls off. The operator should often check the the temperature, sound of the machine and vibrator. Observing the vibrated condition aims to assure whether if the vibration in four corners are in the same frequency and whether if there exists coal leakage and loose triangular belt phenomenon. Always, the effectiveness of dehydrate and de-medium. Checking the condition of the inlet and outlet phenomenon of screen aims to assure whether if it is blocked or normal.

Halting:after all of the materials in the screen have been ejected, the vibration screen can be halted. The operator should observe the screen to check whether if it will clash with other equipment when it go through the point of resonance during halting. When it happens, the machine should be halted immediately. When the machine will jeopard the safety of the operator and machine, or the the area of the screen is stacked with much sundries,or the feeding is not successful, or the screen is damaged serious, or the chute under the screen is blocked seriously, or the straining box shakes violently and or abnormal phenomenons, the fault should be excluded firstly and then restart the system of vibration screen.

Technical specification

Model | Screen surface area | Classification point | Amplitude | Vibration time | Handling capacity | Power | Inclination angle on the screen surface | |||

㎡ | Mm | Long axis | Minor axis | r/min | t/h | Kw | Head | Central | Tail | |

TDS3690 | 32.4 | 5-20 | 8-10 | 3-5 | 800 | 400-950 | 2×55 | 15 | 10 | 5 |

TDS3090 | 27 | 5-20 | 8-10 | 3-5 | 800 | 300-800 | 2×45 | 15 | 10 | 5 |

TDS3075 | 22.5 | 5-20 | 8-10 | 3-5 | 850 | 300-600 | 2×30 | 30 | 20 | 10 |

TDS2575 | 18.75 | 5-20 | 8-10 | 3-5 | 800 | 200-500 | 2×30 | 15 | 10 | 5 |

TDS2460 | 14.4 | 5-20 | 8-10 | 3-5 | 850 | 150-300 | 2×15 | 30 | 20 | 10 |

TDS2060 | 12 | 5 | 10-15 | 4-6 | 850 | 150-200 | 2×15 | 15 | 10 | 5 |

The foregoing attached table shall only be used for reference. The actual application shall be appropriately modified according to customers requirements.

FAQ:

What’s the meaning of the ellipse uniform-thickness in the ellipse uniform-thickness vibrating screen?

Ellipse means that the ellipse uniform-thickness vibrating screen adopts three sets of vibrator devices. The material in the ellipse uniform-thickness vibrating screen will make a ellipse motion. Thus, it is named as ellipse vibrating screen. Why it is named as uniform thickness is that each zone for stacking the materials has the same thickness. It can be called as the the same thick material layer. This model has the highest screening efficient by vibration. It has the greatest performance.

What pattern do the scale board adopt?

There exists various models can the scale board adopt, such as molten plate, PU plate and wear-resisting steel plate.

Generally, what type do the vibrator adopt?

The vibrator will adopt box-type vibrator, which is convenient to maintain and install.

- Q: What is the structure principle of sweet potato starch vibrating screen?

- The moving angle of the material on the screen surface can be changed by the phase angle of the upper section and the lower end, so that the material passes through the screen rapidly and achieves the purpose of sieving

- Q: OK, where can I get the shaker dust collector?

- The vibration screen dust remover is a MC pulse bag filter, which is specially used for dust producing in the vibrating screen. Because of the font difference, some people call it shock screen dust collector.

- Q: What are the advantages of ultrasonic vibrating screen?

- 1. ultrasonic vibration sieve technology for different materials, such as particle size, density and particle shape, screening, research and development and production;2., it has solved the sieving problems of strong adsorption, easy to hold together, strong stickiness, high static electricity, high density, superfine powder and other characteristics;

- Q: What is the difference between exciter and vibrating motor?

- Vibrating screen is a common screening machine, and it has a wide range of applications in all walks of life. From mines to metallurgy, from building materials to electricity, from road construction to food and chemical engineering, there are vibrating screens everywhere. It is no exaggeration to say that without vibrating screens it is impossible to produce qualified, high-quality products.

- Q: What kind of material does the sealing ring of the vibrating screen have?

- Silicon rubber sealing ringSilicon rubber sealing ring is relatively high cost, but the mechanical strength of silicon rubber sealing ring has the advantages of high thermal stability and high adsorption properties, chemical stability, relatively high, such as the correlation with the characteristics of user selected materials, should choose silicone ring.

- Q: What are the unique advantages of a vibrating screen?

- The utility model has the advantages of small size, light weight, convenient movement, simple operation and convenient maintenance.

- Q: How many levels should the vibrating motor of the vibrating screen be equipped with?

- Should match 20-6, power 2. 0KW, level 6. Local purchasing. Strong vibration

- Q: The vibrating screen mesh size and mesh mean the same thing?

- Number is the number of holes, is the number of holes per square inch.Mesh size determines the size of the screen aperture.The greater the number, the smaller the aperture. In general, mesh aperture (x = 15000 micron number).

- Q: What is a vibrating screen for mining?

- Concept: the vibration motor, rubber spring damping, high wear-resistant material tray, sealed sieve box and other domestic and foreign advanced technology and advanced self synchronous vibration principle, has the characteristics of long service life, low noise, high screening efficiency, a vibration screening equipment for sintering ore, natural ore, coke and other powder materials the.

- Q: How to choose eccentric block for direct axis eccentric block vibrating screen

- The six step is to install the vibration motor bearing(1) the bearing seat is mounted on the shell, and if there is grease grease, it must be aligned. Fasten the bearing block with the bolt fastened with coating bolt;(2) the bearings are cylindrical cylindrical roller bearings with inner and outer sleeves, and the bearings shall be sheathed on the rotating shaft and put in place;(3) the protective cover on both ends of the vibrating motor is fastened by screws.(4) with kerosene wash SKF imported bearings, pressure bearing, roller bearing outer ring to fill at Shell No. three to 2/3 full wash grease, evenly, mounted on the bearing cover, with coated bolt fastening bolt pressing bearing gland pine gum;(5) fasten the fastening bolt of the eccentric block, turn the adjustable eccentric block, make it reach the angle before unloading, and tighten the fastening bolt. When the assembly is completed, the shaft shall be axially connected;(6) the inner and outer eccentric blocks are installed on the rotating shaft and are in place. The axle keys shall be loaded into the key slot, and then the outer eccentric block shall be installed. The shaft shall be mounted on the rotating shaft with a retainer ring;

Send your message to us

TDS Ellipse Uniform-Thickness Vibrating Screen,Vibration Screen

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords