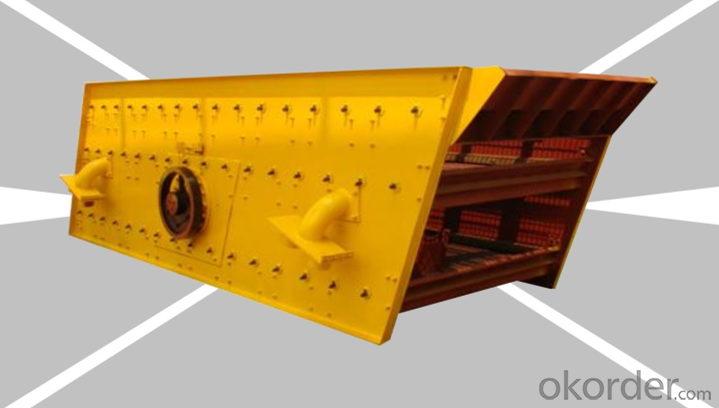

YK Circle Vibrating Screen, Mining Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

With the approximate circle movement, the series of vibrating screen is a kind of multilayer, high-efficient and new-type vibrating screen. Considering that the screen has adopted the boxvibrate eccentric and tyre coupling, the screen can enhance the service life of equipment, meanwhile, the configured spring damping devices can effectively reduce the impact on the foundation, therefore, it has small vibration noise. As the configured device for all kinds of crusher machinery, the screen is mainly used for classifying the mine, coal, building materials, as well as other broken stones, quarrying and dinas. Due to the alternative multilayer screen cloth, it can satisfy the screening requirements of materials with different dimensions,

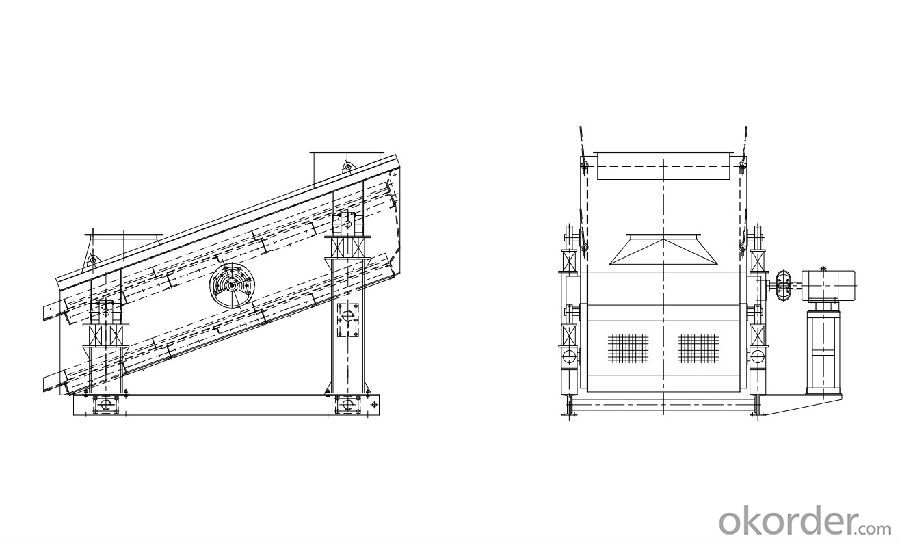

Vibrator:

The eccentric block is equipped on each side plate by means of transmission shaft connection. The vibrator is made up of self-aligning bearing and two shield covers. The eccentric block is mounted on the transmission shaft. By means of changing the angle between the main eccentric blocks and auxiliary eccentric block, it can change the size of the vibrator to get various amplitude.

Straining box: the straining box is the biggest part in YK circular vibrating screen, which is mainly made up of feeder trough, relief trough, side plate, cross girder, screen surface, tension device and other devices. The side plate is made of massive steel plate. The cross girder adopts seamless steel tube. Each soldering lug and side plate are connected with high-strength bolt. The working of the YK circular vibrating screen is reliable. And, the manufacturing and maintaining is simple.

Technical specifical

Model | Rotation speed(r/min) | Number of screening surface layers | Specification of screen deck(mm) | Max. Feeding quantity(mm) | Vibration frequency(r/min) | Tilt(°) | Double amplitude (mm) | Processin ability (t/h) | Physical dimension(mm) | Power(kw) | Weight (t) |

YK1545 | 1000 | 1 | 1500×4500 | 400 | 970 | 10 | 8 | 33-240 | 4805.5×2911×2076 | 11 | 3.9 |

2YK1545 | 1000 | 2 | 1500×4500 | 400 | 970 | 20 | 8 | 32-240 | 5155×3050×3220 | 15 | 4.4 |

2YK1548 | 730 | 2 | 1500×4800 | 200 | 730 | 20 | 8 | 60-270 | 5072×3147×3776 | 15 | 4.9 |

3YK1548 | 970 | 3 | 1500×4800 | 400 | 970 | 20 | 8 | 47-275 | 5011×3086×2653 | 15 | 6 |

4YK1548 | 730 | 4 | 1500×4800 | 200 | 970 | 20 | 8 | 60-250 | 4800×2947×4046 | 18.5 | 7 |

YK1854 | 1000 | 1 | 1800×5400 | 200 | 980 | 20 | 8 | 63-586 | 5400×3247×2750 | 18.5 | 5.1 |

2YK1854 | 970 | 2 | 1800×5400 | 400 | 970 | 20 | 8 | 63-586 | 5200×3400×3911 | 22 | 7.6 |

3YK1854 | 970 | 3 | 1800×5400 | 400 | 970 | 15 | 8 | 51-496 | 6500×3326×3393 | 22 | 8.7 |

4YK1854 | 730 | 4 | 1800×5400 | 400 | 730 | 20 | 8 | 32-310 | 5447×3417×4266 | 30 | 10.5 |

YK2160 | 730 | 4 | 2100×6000 | 400 | 730 | 20 | 8 | 400-600 | 6050×4035×3005 | 18.5 | 5.9 |

2YK2160 | 730 | 2 | 2100×6000 | 400 | 730 | 20 | 8 | 390-560 | 6050×3735×4087 | 30 | 7.8 |

3YK2160 | 740 | 3 | 2100×6000 | 400 | 730 | 20 | 8 | 390-560 | 6050×3934×4594 | 30 | 10.7 |

4YK2160 | 740 | 4 | 2100×6000 | 400 | 740 | 20 | 8 | 66-720 | 6050×3966×5073 | 45 | 11.1 |

YK2460 | 730 | 1 | 2400×6000 | 200 | 730 | 20 | 8 | 450-650 | 6050×4035×3005 | 22 | 6.2 |

2YK2460 | 730 | 2 | 2400×6000 | 200 | 730 | 20 | 8 | 450-650 | 6050×4035×4087 | 30 | 8 |

3YK2460 | 740 | 3 | 2400×6000 | 200 | 740 | 20 | 8 | 450-650 | 6050×4234×4594 | 37 | 10.7 |

4YK2460 | 740 | 4 | 2400×6000 | 200 | 740 | 20 | 8 | 450-650 | 6050×4266×5073 | 45 | 12.8 |

2YK2865 | 730 | 2 | 2800×6500 | 200 | 730 | 20 | 8 | 600-800 | 6500×4407×4618 | 2×22 | 11.4 |

3YK2865 | 740 | 3 | 2800×6500 | 200 | 730 | 20 | 8 | 600-800 | 6500×4407×4618 | 2×22 | 13 |

YK3072 | 740 | 1 | 3000×7200 | 200 | 740 | 20 | 8 | 600-800 | 6766×4607×3365 | 2×18.5 | 10.8 |

2YK3072 | 730 | 2 | 3000×7200 | 200 | 730 | 20 | 8 | 600-800 | 7200×4455×4379 | 2×22 | 11.8 |

3YK3072 | 730 | 3 | 3000×7200 | 200 | 730 | 20 | 8 | 600-800 | 7200×4467×4964 | 2×22 | 15.8 |

YA1848 | 1460 | 1 | 1800×4800 | 400 | 1460 | 20 | 8 | 60-270 | 4976×3023×3002 | 15 | 7 |

YZ1230 | 1500 | 1 | 1200×3000 | 200 | 1490 | 20 | 8 | 12-125 | 3153×2030.5×1611.4 | 5.5 | 1.7 |

3YZ1236 | 1500 | 3 | 1200×3600 | 200 | 1500 | 20 | 8 | 15-150 | 3990×2270.5×2776.3 | 11 | 4.3 |

Supporting device: The elastic component id made of rubber spring. By means of changing the height of back and front support, it can change the the leaning angle of screen. The changed height of support and the size of anchor bolt hole are decided by user.

Sketch

Storage

After the equipment arrives at the destination, the user must check whether if the components are complete in the light of the product list. In the meanwhile, the user must check whether if the product exists flaw and damage caused during the transportation and then record the damage and flaw on the bill of lading. The equipment must be put on flat and smooth ground. On the bottom of the screen, the sleeper must be underlaied for stable installation. When it is put on open yard, it can not touch the ground as well as it can not be soaked. When it is stored, the upper part should be covered for preventing it from erosion by wind and rain.

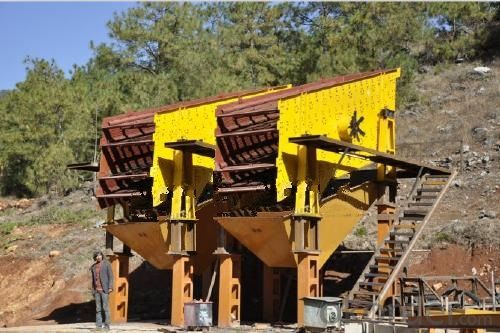

Installation

The installation of the screen must apply the requirement of general drawing on operational spot and the sequence of installation as following:

First of all, it must make foundation leveling. Then, it must install the supporting frame and motor frame and adjust the relative position. After it is fastened, it can install the damping spring in proper order. Before the damping spring is installed, the spring shall be selected according to the actual value of the end marks

Install the screen : firstly, it should transport the screen to the installation site. Lift the screen and make the inclination of the screen conforming to the general drawing and then put it down slowly. The screen must be put on the surface of the damping spring.

Install the electric motor and connect the line. The user must pay attention to the center height. If the screen is installed after it has been transported to the destination over a half year, all of the exciter should be dismounted. Then all of the exciter should be wash again and refuel again.

Install the flexible coupling between the vibration exciter and electric motor. It is considered that the axis of the electric motor and axis of vibration must be coaxial.

Running-in and acceptance inspection

The installation should be checked in accordance with narrated instruction. The screen can be operated through test run with empty load.

The time of test run will be no less than one hour with empty load. During the test run, the user should observe the screen continuously. The starting of the screen be smooth and quick. The vibration of the screen is stable without special noise.

Operating specification

The operator should be familiar with the equipment. And the operator must obey the stipulations on operation, maintenance, safety, sanitation and others in the plant.

Preparation: before the operation of the equipment, the operator must read the duty record and monitoring the equipment. All bolts should be checked to assure whether if it is loose and whether if the screen is in abrasion.

Starting: the starting of the screen must obey the sequence of process system one time.

Structure features

It has advanced structure, strong excitation force and large vibration intensity.

It has small initial vibration quantity.

It can pass through resonance steadily.

It has less screen clogging phenomenon.

Due to the small noise, it can improve the working environment,

It is easy to maintenance the study and durable property.

FAQ

What characteristic do the YK circular vibrating screen include?

The YK circular vibrating screen is convenient to install with simple structure. The max.grading layer can reach four.

What type do the sieve plate adopt?

It adopts general wearable mess grid made of manganese steel. Also it can adopt punching wearable steel plate which is depended on user.

How many vibrator sets do the YK circular vibration have?

The general specification adopts one set vibrator. The larger vibrator will adopt two sets in according to synchronous belt the same direction movement.

- Q: Which is better, a linear vibrating screen or a round vibrating screen?

- The working principle of circular vibrating screen is mainly composed of screen box, a screen, a vibrator and vibration damping spring composed of circular vibrating screen. The vibrator is installed in the sieve box side, by the motor through the belt driven centrifugal force of inertia, forced vibration sieve box.

- Q: What are the differences between a linear vibrating screen and a circular vibrating screen? Where is the vibration screening equipment produced?

- 1, the oldest one is circular vibrating screen, at present has been eliminated, and then 2, linear vibrating screen, DERRICK and SWACO (the most famous two manufacturers) initial production are linear screen, 3, followed by Chinese domestic developed elliptical vibration sieve effect in fact, the SWACO is better than the straight line, discovered this, and then slowly began to elliptical screen, but DERRICK belongs to the rich that people do not adhere to the patent China plagiarism line screen unchanged, but in the screen has been doing research; 4, then SWACO has developed a dual track sieve that is, a sieve can simultaneously achieve two motion, elliptical offline + almost linear trajectory. (the trajectory of the straight line is large and the ellipse trajectory is good.).

- Q: What is the influence of eccentric vibration of the vibrating screen on the rolling bearings?

- The centrifugal force of vibrator eccentric quality work generated when the eccentric shaft bending deflection, leading to the relative quantitative disc feeder bearing inner and outer rings, due to the eccentric vibration will result in the rotation frequency and each order harmonic caused by, so the running of the inertia force and inertia will cause the bearing dynamic reaction force and vibration. Destroy the stable working state of rolling bearings and other components, to generate high-frequency vibration. The analysis and analysis show that when the vibration frequency of the exciter bearing is the same as the natural frequency of the elastic vibration of the sieve case, it will cause the strong vibration of the elastic body of the sieve case.

- Q: Why is the efficiency of the high frequency linear vibrating screen better?

- High frequency high frequency linear vibrating screen, vibration motor speed of 3000 rpm. Because the motor speed of the high frequency and high frequency linear vibrating screen is high, the vibration frequency of the screening machine is higher, and the more materials are processed in unit time, so the output is higher than the ordinary high frequency linear vibrating screen.

- Q: Why is the bearing of the vibrating screen overheated?

- In addition, due to improper selection of lubricant, resulting in a lack of lubrication and heat dissipation and bearing working space is pollution will cause overheating of the bearing. The bearing oil, grease or oil bearing too much or too little pollution, will cause the bearing fever, even damage the bearing.

- Q: What are the differences between MB and Ma bearings for vibration screens?

- Bearing MA room, the outer ring to guide the rolling mode, the specific design of the above bearing roller and inner ring is a gap.

- Q: Is Derek's high frequency vibrating screen the same as an ordinary high frequency vibrating screen?

- The structure of high frequency vibrating screen mainly consists of screen box, vibrator, suspension (or support) device and motor. The motor drives the main shaft of the exciter by the triangle belt belt, and the screen box is vibrating because the centrifugal inertia force of the heavy object is not balanced on the exciter. Different amplitudes can be obtained by changing the eccentric weight of the exciter

- Q: How to change the screen of vibrating screen?

- 1, put the ring screw or, remove the frame, the damaged mesh removed, replaced with a new mesh.2, the mother of online mesh tile in the vibrating screen, put the box back again, around the hands of meshTension, the frame at both ends of the frame and the lower frame at the edge of the box, each with a universal pliers, the upper frameClamp with lower frame.

- Q: What is the main function of plastic vibrating screen?

- Filtration: to filter out impurities in a liquid.

- Q: Can the discharge hole of the linear vibrating screen be adjusted at will?

- Can be customized according to the needs of the design, and can be made into a round, put, can also increase the longer, may also need to design direction.

Send your message to us

YK Circle Vibrating Screen, Mining Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords