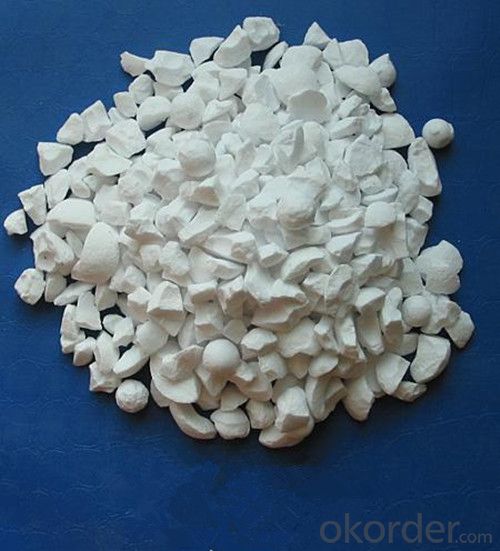

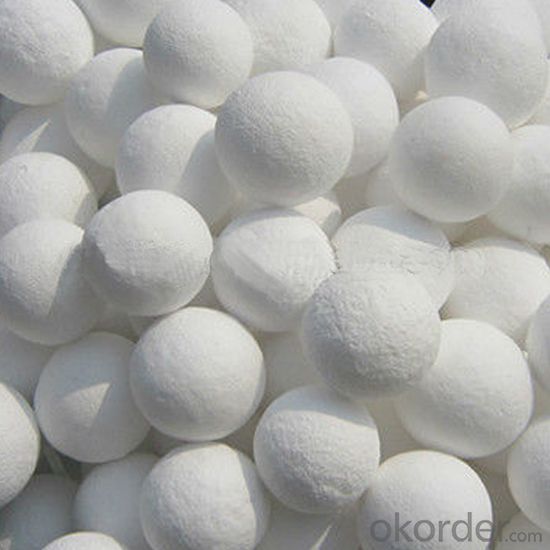

Raw Materials for Refractory:High Purity Tabular Alumina - Good Quality, Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TA TABULAR ALUMINA GOOD QUALITY GOOD PRICE HIGH PURITY

Product Description

Specification of Tabular Alumina

Item | B.D g/cm3 | Absorbing water rate(%) | Porosity | Chemical Composition | |||

AL2O3 | Fe2O3 | SiO2 | NaO2 | ||||

TA | 3.5 | 1.5max | 5.0% | 99.2%min | 0.2% max | 0.2% max | 0.4% max |

Packaging & Shipping

In 1MT jumbo bag or as the buyer request.

We ship the cargo in 20' GP containers,each container loads 25MT/20bags.

Application of Tabular Alumina

1.Excellent insulation raw materials for fire-proof, porcelain and electric instruments.

2.Excellent material for milling tool and polishing milling.

Our Services

1.We will keep the client informed about the cargo situation,from production time to the shipment.

2.We test samples picked up from the plant or loading port in our designated third party lab or SGS lab.We tes sample before every shipment to make sure each lot quality is good for our client.

Picture:

- Q: How to divide the materials according to the National Fireproofing Material Standard?

- according to China's national standard GB8624-97, the combustion performance of construction materials can be divided into several classes: Class A: Incombustible building material: Almost no burning material. Class B1: nonflammable building material: nonflammable material has a good flame resistance effect. when it meet the open fire in the air or burnd at high temperature, it is difficult to spread quickly, and when the fire source is removed, the combustion stop immediately. Class B2: flammable building material: flammable material has a good flame resistance effect. when it meets open fire in the air or at high temperature, it will immediately burst into flames and easily cause fire spread, such as wooden column, timber roof truss, timber beam, and wooden stairs,ect.. Class B3: inflammable building material: No flame resisting effects, highly flammable, high fire risk.

- Q: Which refractory material is better in China? Industrial furnace, mainly in non-ferrous industries, glass kiln, cement kiln business.

- Such solid nano microporous insulation material with nano inorganic refractory powder special, with a huge surface area, nano particles contact between the minimum point contact point contact thermal resistance is very large, the heat conduction effect of the material becomes very small, resulting in heat conduction coefficient of solid such nano porous insulation materials very small; nano pores formed of nanoparticles, the average size of 20 nm, and the average free path of molecular thermal motion at room temperature under static air is 60 nm, thus locking the air molecules in powder within nano pores, making the micro convection heat transfer effect between the stationary air molecules disappeared. The room temperature thermal conductivity of solid such nano microporous insulation material is lower than the static air; at high temperature, the main effect of heat transfer heat radiation, Good energy-saving insulation materials with nano microporous infrared additive special, stop at a high temperature and reflected infrared radiation, reduce the heat radiation effect to the lowest point, the radiation heat transfer coefficient of materials under high temperature is reduced to the lowest value.

- Q: Who knows the fire resistant level of the rock wool color plate?

- The rock wool color steel rock wool board is used in a area of high ??fire safety requirements. According to "interior decoration of buildings for fire protection design", the color steel rock wool board belongd to level A. Its life is more than 15 years and still can be used when the temperature is up to about 700 ℃, with maximum fireproofing hour of six hours. And the rock wool color plate is a environmentally friendly material, the preferred material in the construction industry .

- Q: what kind of fireproof materials is used for high rise buildings?

- steel is recommended As a form of high-rise building structure, steel is widely used especially in the ultra-high-rise and long span construction showing strong vitality, for its high strength, light weight, and good extensibility, resistance to shock and short construction period. The mechanical strength of steel decreases with rising temperature at about 5000 ℃, decreasing about 40%-50%. the mechanical properties of steel, such as yield points, compressive strength, elastic modulus, and load capabilities have declined rapidly , quickly losing their ability to support, leading to building collapse. Therefore, it is imperative to protect steel structures. Brushing or spraying the coating on the surface of steel structure to prevent burning and insulate heat. It also prevents undermining the rolled steel from rapid temperature elevation and avoid collapse of building for lose of supporting capacities.

- Q: Refractory factory grinding brick dust harmful to the body?

- Therefore, in the workshop work must pay attention to do their own protection.

- Q: How to make use of waste refractory materials whose main elements are alumina and mullite?

- Crushing and pressing refractory bricks, or refractory parts . Such as welding positioner tracks use disposable tools.

- Q: What are the raw materials of refractory?

- Of course, different types have different raw materials: Magnesite (the electric?smelting: alkaline refractory, magnesia-carbon bricks, alkaline, high-purity) + crystalline flake graphite + phenolic resin + additive (silicon powder, aluminite powder, silicon carbide powder, or high-temperature asphalt,etc.) , acidic refractory: The neutral is not easy to answer. such as. You can check out the classification, such as

- Q: Are refractory materials and fireproofing materials the same?

- Refractory materials is flammable when it is reached certain temperature for a certain time, but it will not support burning when there is no open fire (such as: gypsum board). Fireproofing material reaches A grade and it is non-combustible itself.

- Q: For refractory, why is it necessary to store the first mixing materials for some time under proper moisture and temperature?

- It is mainly to remove gas form chemical reactions in the pug, give full play to plasticity and binding properties of combined, and store unburned?brick whose cememting agent is phosphoric?acid or aluminium?phosphate for some time under proper moisture and temperature. For example, to avoid the formed bricks in the initial stage of drying and firing form cracking due to hydration of calcium oxide. Mixing materials is to store the first mixing materials for some time under proper moisture and temperature in order to improve the evenness and moldability of pud, such as making the distribution of combined clay and water more even. The length of storing chiefly depends on the process requirements and the characteristics of blanks. For the producing pug of high temperature kiln furnitures, the storing time is longer. The function of storing mxing materials varies with different natures of blanks. For honeycomb ceramics, it is to fully digest calcium oxide in blanks. For storing magnesia brick blanks containing much calcium oxide, it should be stored for some time in proper humidity and temperature.

- Q: How do refractory materials apply into pyrophyllite?

- When it is sized, add some clinker and after calcination, aggregate will be finished. From: turn to help

Send your message to us

Raw Materials for Refractory:High Purity Tabular Alumina - Good Quality, Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords