Stucco Embossed Aluminum Sheet with Different Specifications - Aluminum Transition Strips for Carpet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: shutters,bicycles, doors...

(2).Exterior: renovations...

(3).Advertisement: fascia, shop fronts...

3. Feature of Aluminum

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

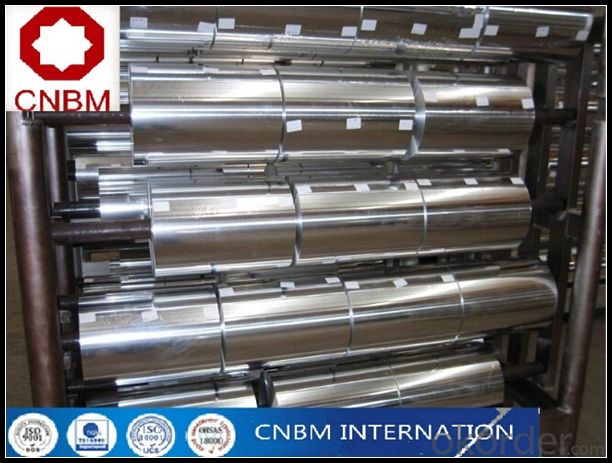

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Which is the best aluminum alloy belt?

- Of course, choose Jiangsu Yang Dong Aluminum Co., Ltd., specializing in the production of aluminum and aluminum alloy, high precision machining, spot warehousing, product sales, technical consulting in one of the large-scale comprehensive import and export of aluminum materials spot sales.

- Q: This question asks for a comparison of various types of aluminum siding used in construction, highlighting their unique characteristics and differences.

- <p>Aluminum siding comes in various types, each with unique properties. Interlock siding features overlapping panels for better protection against weather. Insulated siding offers thermal efficiency with a foam core. Vertical siding is known for its traditional look and is often used in commercial settings. Shake-style siding mimics the appearance of wood shakes, providing a rustic aesthetic. Soffit siding is designed for use around windows and eaves, offering a clean finish. Each type varies in terms of durability, maintenance requirements, and cost, with applications ranging from residential to commercial construction.</p>

- Q: Is it possible to utilize aluminum strips for a personal roofing project?

- <p>Yes, you can use aluminum strips for your own roofing project. Aluminum is a popular choice due to its durability, lightweight, and resistance to corrosion. It's easy to work with and can be cut and shaped to fit various roofing designs. However, it's crucial to ensure proper installation, as aluminum expands and contracts with temperature changes, requiring appropriate fastening and sealing to prevent leaks. Always follow local building codes and consult with a professional if you're unsure about the installation process.</p>

- Q: What are the potential health risks related to the use of aluminum foil?

- <p>While aluminum foil is widely used in cooking and food storage, there is limited evidence to suggest significant health risks. Some studies have linked aluminum exposure to neurological conditions like Alzheimer's, but the connection is not conclusive. The body does not absorb significant amounts of aluminum from foil, especially when used properly. However, it's important to avoid wrapping acidic or highly acidic foods in aluminum foil, as this could potentially lead to increased aluminum leaching. Overall, using aluminum foil in moderation and following proper food handling practices can minimize any potential risks.</p>

- Q: What benefits does using aluminum strips have compared to steel sheets?

- <p>Aluminum strips offer several advantages over steel sheets, including lower weight, which reduces the overall weight of products and can lead to fuel savings in transportation. They also have superior corrosion resistance, making them ideal for outdoor applications. Aluminum is easier to form and shape, which can simplify manufacturing processes. Additionally, aluminum has excellent thermal conductivity, which is beneficial in applications requiring heat dissipation. Lastly, aluminum is more environmentally friendly due to its recyclability and lower energy consumption in production.</p>

- Q: Is it possible to use aluminum strips as materials for roofing membranes?

- <p>Yes, aluminum strips can be used for roofing membranes. They are known for their durability, corrosion resistance, and lightweight properties, making them suitable for various roofing applications. Aluminum strips can be used in the form of standing seam metal roofs, which are popular for their sleek appearance and strength. They are also low maintenance and can be recycled, contributing to their environmental sustainability. However, it's important to ensure proper installation and sealing to prevent leaks and maintain the integrity of the roof.</p>

- Q: Is it possible to use aluminum strips to repair a wall that has been damaged by water?

- <p>Yes, aluminum strips can be used to cover a wall damaged by water, but it's not the most effective solution. Aluminum strips are typically used for decorative purposes or as a protective layer in certain applications. For water-damaged walls, it's better to first address the underlying issue, such as fixing leaks or improving drainage. Then, repair the damaged area with appropriate materials like drywall or plaster, followed by painting or other finishing touches. Using aluminum strips without proper repair may lead to further damage or an unsightly appearance.</p>

- Q: Is it possible to use aluminum strips to construct a solar reflector system for residential or commercial purposes?

- <p>Yes, you can use aluminum strips to create a solar reflector system for your home or business. Aluminum is a reflective material and can be shaped into strips to reflect sunlight. These strips can be arranged in a way to direct sunlight towards solar panels or into specific areas to reduce the need for artificial lighting and heating. However, for optimal efficiency, you should consider the angle of reflection, the positioning of the strips relative to the sun's path, and the overall design of the system. Consulting with a professional in solar technology can help ensure that your solar reflector system is effective and safe.</p>

- Q: Is it possible to use aluminum strips as a material for exterior wall cladding?

- <p>Yes, aluminum strips can be used for exterior cladding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum cladding is lightweight, which makes it easier to install compared to heavier materials. It also offers excellent weather resistance and can be painted or finished in various ways to enhance the appearance of a building. Additionally, aluminum is a sustainable choice as it can be recycled, contributing to environmental sustainability.</p>

- Q: What are the specific types of coatings applied to aluminum strips to enhance their durability?

- <p>Yes, there are specific coatings used for aluminum strips to increase their durability. These include anodizing, which forms a protective oxide layer on the surface, and various chemical conversion coatings like chromate and phosphate treatments. Additionally, organic coatings such as polyester, epoxy, and acrylic can be applied for corrosion resistance and improved surface properties. Physical vapor deposition (PVD) and hot-dip galvanizing are also used for enhanced durability and protection against environmental factors.</p>

Send your message to us

Stucco Embossed Aluminum Sheet with Different Specifications - Aluminum Transition Strips for Carpet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords