Strips of Aluminum for Aluminum Plastic Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

Aluminum strip is widely used in industry, such as packaging & building industry. Because the good anti heat and anti wet specification. it's very good for Pipe system materials. Normally it's outside bright and inside matt.

2.Specification and Application

Specification

| Alloy | 1050/1060/8011 |

| Temper | Soft |

| Process | DC / CC |

| Thickness | 0.2~0.5mm |

| Width | As required |

| Core ID | As required |

Property

| Tensile strength | ≥100Mpa |

| Elongation | ≥20% |

| Tolerance of size | As GB Standard |

3. Advantages

We've been specialized in aluminium for more than ten years, we know this product very well, and we have good finacial support from government. And also flexible payment term and fast delivery.

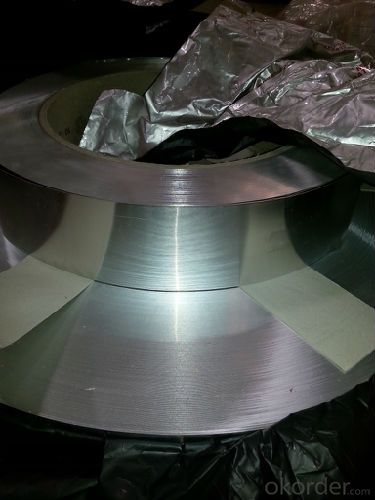

4. Pictures

5. FAQ

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your minimum order quantity?

3tons per size.

- Q: Is it possible to utilize aluminum strips for constructing outdoor decking or railings?

- <p>Yes, aluminum strips can be used for outdoor decking or railings. They are known for their corrosion resistance, low maintenance, and durability, making them suitable for outdoor applications. Aluminum is lightweight, strong, and can withstand various weather conditions without rusting. However, it's essential to ensure that the aluminum is of high quality and properly treated to maintain its performance over time. Additionally, it's crucial to follow proper installation practices to ensure safety and longevity.</p>

- Q: Is it possible to join aluminum strips together through welding?

- <p>Yes, aluminum strips can be welded. Welding aluminum requires specific techniques and equipment due to its high thermal conductivity and reactivity. Common methods include gas tungsten arc welding (GTAW), also known as TIG welding, and gas metal arc welding (GMAW), or MIG welding. These processes involve using a filler material and an inert shielding gas to prevent oxidation. Proper preparation, such as cleaning the aluminum surface and controlling the heat input, is crucial for a successful weld.</p>

- Q: What benefits are associated with the use of aluminum strips on the exterior walls of buildings?

- <p>Aluminum strips for exterior walls offer several advantages, including durability, resistance to corrosion and weathering, and low maintenance requirements. They are lightweight, which can reduce the load on the building structure. Aluminum strips also provide excellent heat insulation properties, contributing to energy efficiency. Additionally, they can be easily shaped and bent, allowing for versatile and modern architectural designs. The recyclability of aluminum makes it an environmentally friendly choice, and its non-combustible nature enhances safety in construction.</p>

- Q: This question asks for a comparison between aluminum strips and other common roofing materials, highlighting their distinct characteristics.

- <p>Aluminum strips are lightweight, corrosion-resistant, and have a long lifespan, making them ideal for roofing applications. They are also recyclable and can be easily bent and shaped. In contrast, other roofing materials like asphalt shingles are more affordable but have a shorter lifespan and are less eco-friendly. Metal roofing, similar to aluminum, is durable but can be heavier and more expensive. Clay and concrete tiles offer a traditional aesthetic but are heavy, require more maintenance, and are prone to breakage. Wood shakes and shingles are renewable but are less fire-resistant and have a shorter lifespan compared to aluminum.</p>

- Q: Which is better, an aluminum belt excavator or a tire excavator?

- Crawler for complex terrain, strong applicability and maneuverability is weak; tire flexibility, can be a wide range of mobile operations, operations such as cement or asphalt pavement crawler excavator can not enter, but only suitable for light duty work

- Q: Is it possible to utilize recycled aluminum for the production of roofing materials for residential use?

- <p>Yes, you can use recycled aluminum to make roofing materials for your home. Recycled aluminum is not only environmentally friendly but also cost-effective. It maintains the same properties as new aluminum, making it suitable for various applications, including roofing. Recycled aluminum roofing materials are durable, lightweight, and resistant to corrosion, which are desirable qualities for any roofing system. However, it's important to ensure that the recycled aluminum is sourced from a reputable supplier to guarantee quality and safety.</p>

- Q: What benefits does using aluminum strips provide compared to other materials?

- <p>Aluminum strips offer several advantages over other materials, including high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity. They are lightweight, which is beneficial for reducing the weight of structures or products. Aluminum's resistance to corrosion means it requires less maintenance and has a longer lifespan. Additionally, its thermal conductivity makes it suitable for applications where heat transfer is important, such as in heat sinks or cookware. Aluminum strips are also easy to work with, allowing for easy fabrication and customization, and they are cost-effective, making them a popular choice in various industries.</p>

- Q: How can the aluminium band be welded to the steel shell?

- Aluminum strip can be welded to the steel shell, mainly to see the aluminum strip thickness, to select the welding method and welding materials according to thickness.

- Q: Is it possible to utilize aluminum strips in the construction of car covers or covers for other types of vehicles?

- <p>Aluminum strips can be used for car covers or covers for other vehicles, but their application is limited. Aluminum is lightweight and corrosion-resistant, which are desirable properties for vehicle covers. However, it lacks the flexibility and durability of materials like fabric or vinyl, making it less suitable for covering vehicles. Aluminum strips might be used as a reinforcement in the edges or corners of a cover, but they are not typically the primary material for the cover itself. It's important to consider the specific needs and conditions that the cover will be subjected to when choosing materials.</p>

- Q: Explain the impact of aluminum strips on indoor air quality, including any potential benefits or drawbacks.

- <p>Aluminum strips themselves do not directly affect indoor air quality. They are often used in construction and design for their strength and lightweight properties. However, if aluminum strips are improperly treated or coated with harmful chemicals, they could potentially off-gas and contribute to poor indoor air quality. Additionally, aluminum strips can sometimes be used in conjunction with air purifiers or ventilation systems, where they might help in filtering out pollutants. It's essential to ensure that any materials used in indoor spaces are safe and do not release harmful substances into the air.</p>

Send your message to us

Strips of Aluminum for Aluminum Plastic Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords