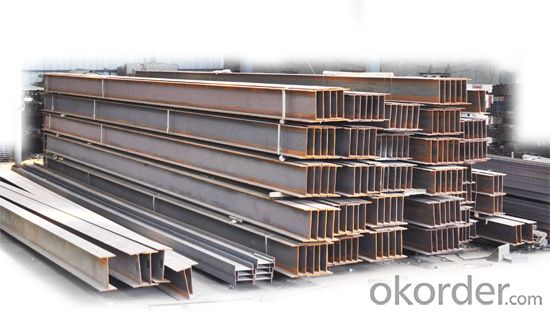

Steels Manufacture Building Material Construction Made in China China on Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Packaging & Delivery

Packaging Detail: | in bundles or as customer's requirement |

Delivery Detail: | Within 30days after receiving your deposit or copy of L/C |

2.Specifications

HRB400,HRB500 Steel Rebars

1.China direct supplier

2.Best service

3.Competitive price

4.Quantity assured

3.Product Description

Name | High Tensile Export Reinforcing Steel Bar ,Deformed Steel Bar ,HRB400B,HRB,46B,HRB500 Building Construction Material |

Standard | ASTM A615 /BS BS 4449 /GB HRB/ JIS G3112 |

Grade | A615 Gr40/60/75 BS 4449 Gr460,B500 GB HRB335,HRB400 ,HRB500

JIS G3112 SD390

|

Diameter | 6mm-40mm |

Length | 6-12m |

Technique | Low temperature hot-rolling reinforcing deformed steel rebar |

Tolerance | As the standard or as your requirement |

Application | Building, construction, road, bridge,etc |

Certificated | BV |

MOQ | 500tons per size steel rebar |

Packing details | Steel rebar packed in bundle or as your requirement |

Delivery | Within 30 days after deposit |

Payment | T/T or L/C |

4.Chemical Composition

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%)

| ||||||

≥400 | ≥470 | ≥14 | ||||||

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB500 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

≥500 | ≥630 | ≥12 | ||||||

5. Theorectical weight

Diameter (MM) | Cross Sectional Area (MM2) | Theorectical Weight (KG/M) | Weight of 12M Bar (KG) | A Ton Contains 12M Bars (PCS) |

6 | 28.27 | 0.222 | 2.664 | 375.38 |

8 | 50.27 | 0.395 | 4.74 | 210.97 |

10 | 78.54 | 0.617 | 7.404 | 135.06 |

12 | 113.1 | 0.888 | 10.656 | 93.84 |

14 | 153.9 | 1.21 | 14.52 | 68.87 |

16 | 201.1 | 1.58 | 18.96 | 52.74 |

18 | 254.5 | 2 | 24 | 41.67 |

20 | 314.2 | 2.47 | 29.64 | 33.74 |

22 | 380.1 | 2.98 | 35.76 | 27.96 |

25 | 490.9 | 3.85 | 46.2 | 21.65 |

28 | 615.8 | 4.83 | 57.96 | 17.25 |

32 | 804.2 | 6.31 | 75.72 | 13.21 |

36 | 1018 | 7.99 | 98.88 | 10.43 |

40 | 1257 | 9.87 | 118.44 | 8.44 |

- Q: How do steel pipes handle thermal expansion and contraction?

- Steel pipes handle thermal expansion and contraction by allowing for slight movement and flexibility. When heated, the steel pipe expands, and when cooled, it contracts. To accommodate these changes, expansion joints or loops are often incorporated into the pipe system. These joints or loops allow the pipe to expand and contract without causing stress or damage. Additionally, proper insulation and support are essential to minimize the effects of thermal expansion and contraction on steel pipes.

- Q: How are steel pipes used in the manufacturing of pressure vessels?

- Steel pipes are commonly used in the manufacturing of pressure vessels as they provide the necessary strength and durability to withstand high internal pressure. These pipes are welded or seamless and are often used as the main structural component of the vessel. They allow for the efficient flow of fluids or gases within the vessel and provide a reliable and secure containment system for various industrial applications.

- Q: How are steel pipes used in high-rise buildings?

- Steel pipes are commonly used in high-rise buildings for various purposes. They are primarily used for structural support as they provide strength and durability, allowing the building to withstand the vertical loads and forces that occur due to its height. Steel pipes are also used for plumbing systems, carrying water and other fluids throughout the building. Additionally, they can be used for HVAC systems, providing ventilation and air conditioning to each floor. Overall, steel pipes are integral components in high-rise buildings, ensuring the safety, functionality, and comfort of the occupants.

- Q: How do steel pipes perform in earthquake-prone regions?

- Steel pipes perform well in earthquake-prone regions due to their inherent strength and flexibility. They can withstand the strong seismic forces, thanks to their high tensile strength and ductility. Steel pipes have the ability to absorb and dissipate energy during an earthquake, reducing the chances of structural failure. Additionally, their durability and resistance to corrosion make them suitable for long-term use in such regions.

- Q: How do steel pipes withstand high pressure and temperature?

- Steel pipes are able to withstand high pressure and temperature due to their inherent properties and construction. Steel is known for its strength and durability, making it an ideal material for pipes used in demanding applications. Firstly, steel pipes are made from high-quality steel alloys that have been specifically designed to withstand extreme conditions. These alloys are chosen for their high tensile strength, which allows the pipes to withstand the internal pressure exerted by fluids or gases flowing through them. The steel used in these pipes is often alloyed with other elements such as chromium, molybdenum, or nickel to enhance its resistance to corrosion and high temperatures. Secondly, the construction of steel pipes plays a crucial role in their ability to withstand high pressure and temperature. Steel pipes are typically manufactured using a seamless or welded process. Seamless pipes are made by piercing a solid steel billet, resulting in a continuous and uniform pipe with no seams or joints. This seamless construction eliminates weak points and ensures that the pipe can handle high pressure without any risk of leakage. Welded pipes, on the other hand, are made by joining two or more pieces of steel together using a welding process. The welds are carefully inspected and tested to ensure their integrity and strength. Although welded pipes may have seams, they are equally capable of withstanding high pressure and temperature when manufactured to the appropriate standards. Additionally, steel pipes can be further reinforced to enhance their resistance to pressure and temperature. For instance, pipes used in extremely high-pressure applications may be thicker or have additional layers of protective coatings. These measures help to increase the strength and durability of the pipes, allowing them to withstand even higher pressures and temperatures. In summary, steel pipes are able to withstand high pressure and temperature due to the strength and durability of the steel alloys used in their construction. The seamless or welded construction of these pipes eliminates weak points and ensures their ability to handle extreme conditions. Additional reinforcement and protective coatings can be applied to further enhance their resistance to pressure and temperature.

- Q: How are steel pipes classified according to their use?

- Steel pipes are classified according to their use based on factors such as their diameter, wall thickness, and the intended application.

- Q: How are steel pipes used in underground drainage systems?

- Steel pipes are commonly used in underground drainage systems due to their durability and strength. They are typically used to carry and transport wastewater and stormwater away from buildings and structures to a designated disposal area or treatment facility. The corrosion-resistant nature of steel pipes ensures a long lifespan, making them a reliable choice for underground drainage applications. Additionally, steel pipes can withstand high water pressure and are often used in larger diameter pipes to handle a higher volume of water flow.

- Q: How are steel pipes used in the mining industry?

- Steel pipes are commonly used in the mining industry for various purposes such as transporting water, slurry, and other materials, as well as for ventilation and support systems in underground mines.

- Q: How are steel pipes classified based on their thickness?

- Steel pipes are classified based on their thickness into three categories: standard, extra strong, and double extra strong.

- Q: Is the steel frame on each floor supporting formwork (floor) called full scaffolding?

- After the use of full scaffolding, more than 3.6 meters of interior wall decoration is no longer calculated decorative scaffolding, and the interior wall of the scaffolding is still in accordance with the provisions of the scaffolding.

Send your message to us

Steels Manufacture Building Material Construction Made in China China on Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords