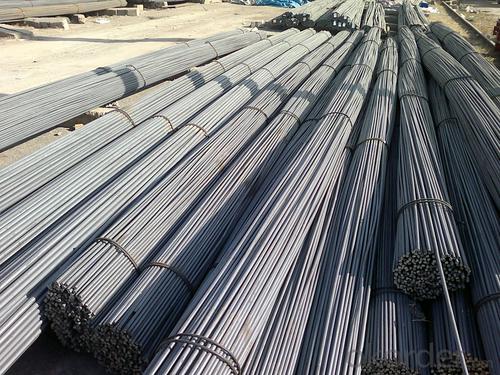

Steel Round Bar with Material Q195/Q235 Made in China for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Steel Round Bar with Material Q195/Q235 Made in China for Sale at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Round Bar with Material Q195/Q235 Made in China for Sale are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Round Bar with Material Q195/Q235 Made in China for Sale are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Packaging Details:

Products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: How soon can we receive the product after purchase?

A2: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workday.

Q3: Why buy Materials & Equipment from OKorder.com?

A3: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Images:

- Q: What is the impact strength of a steel round bar?

- The impact strength of a steel round bar refers to its ability to withstand sudden applied forces or shock loads without fracturing or breaking. It is usually measured in terms of energy absorbed during impact testing, such as the Charpy or Izod test. The exact impact strength can vary depending on the specific grade and heat treatment of the steel, but steel round bars are generally known for their high impact strength, making them suitable for applications requiring resistance to sudden impacts or dynamic loads.

- Q: Can steel round bars be used for making exhaust systems?

- Yes, steel round bars can be used for making exhaust systems. Steel is a commonly used material for exhaust systems due to its durability, heat resistance, and cost-effectiveness. Steel round bars can be shaped and welded to create the necessary components for an exhaust system, such as pipes and mufflers. However, it is important to consider the specific requirements and regulations for exhaust systems in terms of material composition and performance.

- Q: What are the typical tolerances for steel round bars?

- The typical tolerances for steel round bars can vary depending on the specific requirements of the application or industry. However, there are generally accepted standard tolerances that are commonly used. For diameter, the typical tolerances for steel round bars are usually within a few thousandths of an inch. This means that the actual diameter of the bar can deviate slightly from the specified diameter, but it will still fall within an acceptable range. In terms of straightness, steel round bars are commonly produced with a straightness tolerance that allows for some deviation from a perfectly straight line. The typical tolerance for straightness is usually measured in units of inches per foot or millimeters per meter. This means that the bar may have a slight bend or curve, but it should not exceed the specified tolerance. Surface finish is another important aspect of steel round bars. The typical tolerance for surface finish is usually specified in terms of roughness average (Ra) or surface roughness in micrometers. This tolerance ensures that the surface of the bar is smooth and free from any significant imperfections, such as pits or scratches. It is important to note that these typical tolerances can vary depending on the specific grade or type of steel being used, as well as the intended application. In some cases, tighter tolerances may be required for precision or critical applications, while looser tolerances may be acceptable for less demanding applications. Therefore, it is always recommended to consult the relevant industry standards or specifications to determine the specific tolerances required for a particular steel round bar.

- Q: What are the advantages of using nickel-silicon alloy steel round bars?

- Using nickel-silicon alloy steel round bars offers several advantages. Firstly, this alloy provides excellent resistance to corrosion and oxidation, making it highly durable and suitable for various applications in harsh environments. Secondly, the presence of nickel enhances the material's strength and toughness, making it ideal for use in high-stress applications. Additionally, the silicon content improves the alloy's heat resistance, allowing it to withstand elevated temperatures without significant deformation. Overall, nickel-silicon alloy steel round bars offer a combination of corrosion resistance, strength, toughness, and heat resistance, making them a preferred choice in numerous industries such as aerospace, automotive, and chemical.

- Q: Can steel round bars be used for making bicycle frames or handlebars?

- Yes, steel round bars can be used for making bicycle frames or handlebars. Steel is a commonly used material in bicycle manufacturing due to its strength, durability, and affordability. Round bars made of steel provide excellent rigidity and stability, which are essential for ensuring the structural integrity of a bicycle frame or handlebars. Additionally, steel has a high tensile strength, allowing it to withstand the stresses and strains experienced during cycling. It is worth noting that different types of steel, such as chromoly steel, may be preferred for bicycle frames and handlebars as they offer specific advantages such as improved strength-to-weight ratio. However, in general, steel round bars are a suitable choice for constructing bicycle frames and handlebars.

- Q: What are the disadvantages of using steel round bars?

- There are a few disadvantages associated with using steel round bars. Firstly, steel round bars can be quite heavy, making them difficult to handle and transport. Secondly, steel round bars can corrode if not properly protected, which can lead to structural weakness and reduced lifespan. Additionally, steel round bars may not be suitable for certain applications that require lightweight or non-magnetic materials. Lastly, steel round bars can be more expensive compared to other materials, which may impact the overall project cost.

- Q: What are the different types of steel round bar surface treatments?

- There are several different types of surface treatments that can be applied to steel round bars to enhance their appearance, durability, and resistance to corrosion. Some of the most common surface treatments include: 1. Hot-dip galvanizing: This process involves immersing the steel round bar in a bath of molten zinc to create a protective zinc coating. This coating helps to prevent rust and corrosion, making it ideal for outdoor applications. 2. Electroplating: Electroplating involves coating the steel round bar with a layer of another metal, such as chrome or nickel. This not only enhances the appearance of the bar but also improves its resistance to corrosion. 3. Powder coating: In this process, a dry powder is applied to the surface of the steel round bar electrostatically and then cured under heat. This creates a hard, durable, and attractive finish that is resistant to chipping, scratching, and fading. 4. Passivation: Passivation is a chemical process that removes impurities from the surface of the steel round bar, leaving behind a clean and corrosion-resistant layer. This treatment is commonly used for stainless steel bars to enhance their resistance to rust. 5. Black oxide coating: Black oxide coating is a conversion coating that forms a thin layer of black iron oxide on the surface of the steel round bar. This treatment provides mild corrosion resistance and also gives the bar a sleek black appearance. 6. Shot blasting: Shot blasting involves propelling abrasive materials at high speeds onto the surface of the steel round bar to remove any impurities or scale. This treatment not only improves the appearance but also creates a roughened surface that promotes better adhesion of coatings. 7. Acid pickling: Acid pickling is a process that removes scale and impurities from the surface of the steel round bar by immersing it in an acid bath. This treatment leaves the surface clean and free from any contaminants. These are just a few examples of the various surface treatments available for steel round bars. The choice of treatment depends on factors such as the intended use of the bar, the desired appearance, and the level of corrosion resistance required.

- Q: What is the tensile strength of a steel round bar?

- The tensile strength of a steel round bar can vary depending on the specific grade and manufacturing process. However, in general, steel round bars have a high tensile strength, typically ranging from 400 to 700 megapascals (MPa).

- Q: How do you calculate the weight of a steel round bar based on its length and diameter?

- The weight of a steel round bar can be determined by utilizing the subsequent equation: Weight = (π/4) x (Diameter^2) x Length x Density. In this equation, π denotes the mathematical constant pi, with an approximate value of 3.14159. Diameter represents the measurement across the widest point of the steel round bar, while Length corresponds to the overall length of the bar. Additionally, Density signifies the typical density of steel, which is approximately 7850 kilograms per cubic meter. To calculate the weight, first square the diameter and then proceed to multiply it by the length and density. Finally, multiply the outcome by π/4 to obtain the weight of the steel round bar in the desired units, typically kilograms or pounds. It is crucial to acknowledge that this equation assumes the steel round bar is a solid cylinder with a uniform diameter. If there are any variations or irregularities present in the bar, the weight determined using this equation may not be entirely accurate.

- Q: What are the different heat treatment processes used for steel round bars?

- There are several heat treatment processes that are commonly used for steel round bars to enhance their mechanical properties and improve their overall performance. These processes include annealing, normalizing, quenching, tempering, and case hardening. 1. Annealing: This process involves heating the steel round bars to a specific temperature and then cooling it slowly to relieve internal stresses and improve its ductility. Annealing also refines the grain structure of the steel, making it softer and more workable. 2. Normalizing: Similar to annealing, normalizing involves heating the steel round bars to a specific temperature, but in this case, it is cooled in still air. Normalizing helps to refine the grain structure and improve the steel's mechanical properties, such as strength and toughness. 3. Quenching: Quenching is a rapid cooling process that involves immersing the steel round bars in a quenching medium, such as oil, water, or polymer. This process is used to achieve high hardness and strength by transforming the steel's microstructure, known as martensite formation. However, quenching can also make the steel more brittle, so it is often followed by tempering. 4. Tempering: Tempering is a heat treatment process that involves reheating the quenched steel round bars to a specific temperature and then cooling it slowly. This process helps to reduce the brittleness caused by quenching and improves the steel's toughness and ductility. The temperature and duration of tempering can be adjusted to achieve the desired mechanical properties. 5. Case hardening: Case hardening is a surface heat treatment process used to increase the hardness and wear resistance of the steel round bars. It involves introducing carbon or other alloying elements to the surface of the steel and then heating it to a specific temperature. This process forms a hardened outer layer while maintaining a tough core. These different heat treatment processes provide steel round bars with a wide range of mechanical properties and performance characteristics, allowing them to be used in various applications, including automotive, construction, manufacturing, and aerospace industries. The specific heat treatment process selected depends on the desired properties, the steel composition, and the intended application of the round bars.

Send your message to us

Steel Round Bar with Material Q195/Q235 Made in China for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords