Steel pipe for carbon seamless ,10#-45#, cnbm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

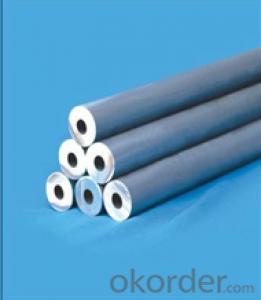

Thickness: 6 - 50 mm Section

Shape: Round,r

Outer Diameter: 33 - 600 mm

Secondary Or Not: Non-secondary

Application: Fluid Pipe

Technique: Hot Rolled,Hot Rolled,Cold Drawn,Hot Expanded Certification: API Surface Treatment: Beveled end or plain end or varnished as per buyer

Special Pipe: API Pipe Alloy Or Not: Non-alloy

Brand Name: XPY(Xinpengyuan)

Length: 6-12m or according to clients' requirements

Standard: BS 3059-2,JIS G3454-2007,GB 5310-1995,GB 3087-1999,GB/T 8163-1999,GB/T 8162-1999,GB 6479-2000,DIN 1629/3,DIN 2448,ASTM A106-2006,ASTM A53-2007,API 5CT,API 5L,BS,JIS,GB,DIN,ASTM,API

Packaging Detail: Beveled end , plain end, varnished, or adding plastic caps/ according to customers' request

- Q: How are steel pipes protected against galvanic corrosion?

- Steel pipes are protected against galvanic corrosion through various methods including the application of protective coatings such as zinc or epoxy, cathodic protection systems, and the use of corrosion inhibitors.

- Q: How do you determine the required wall thickness for steel pipes?

- The required wall thickness for steel pipes is determined by considering various factors such as the internal pressure, external loads, pipe material, and the desired safety factor. This is typically calculated using engineering principles, industry standards, and specific pipe design codes to ensure the pipe can withstand the anticipated conditions without failure or deformations.

- Q: Can steel pipes be used for shipbuilding?

- Yes, steel pipes can be used for shipbuilding. Steel is a commonly used material in the construction of ships due to its strength, durability, and resistance to corrosion. Steel pipes are used for various purposes in shipbuilding, including the construction of the ship's hull, superstructure, and various internal systems such as plumbing, ventilation, and fuel lines. The strength and structural integrity of steel pipes make them suitable for withstanding the harsh conditions at sea, such as high pressures, extreme temperatures, and exposure to saltwater. Additionally, steel pipes can be easily welded and shaped to meet the specific requirements of shipbuilding, making them a versatile choice for this industry.

- Q: Can steel pipes be used for conveying abrasive materials?

- Yes, steel pipes can be used for conveying abrasive materials. Steel pipes are known for their durability and resistance to wear and tear, making them suitable for transporting abrasive substances such as sand, gravel, or chemicals. Additionally, steel pipes can handle high pressure and temperature conditions, further contributing to their suitability for conveying abrasive materials.

- Q: What is the role of steel pipes in HVAC systems?

- Steel pipes are crucial components in HVAC systems as they are used to transport hot and cold water throughout the system. They provide a durable and reliable means of distributing heat or cooling energy to various parts of a building. Steel pipes are known for their high strength and resistance to corrosion, making them an ideal choice for HVAC applications.

- Q: Can steel pipes be coated for aesthetic purposes?

- Indeed, steel pipes have the potential to be coated solely for aesthetic reasons. By applying coatings to steel pipes, not only can one achieve an attractive appearance, but also safeguard them against corrosion and other environmental influences. Numerous coating choices are at one's disposal when it comes to steel pipes, including powder coating, epoxy coating, and vinyl coating, among others. These coatings can be employed in various colors and textures to enrich the pipes' visual appeal and harmonize with their surroundings. Whether utilized in industrial settings, architectural endeavors, or for decorative purposes, the act of coating steel pipes has the power to metamorphose them into visually captivating components, all while preserving their structural integrity.

- Q: How are steel pipes coated to prevent external corrosion?

- Steel pipes are commonly coated to prevent external corrosion through various methods such as applying a layer of protective paint, using epoxy or polyethylene coatings, or galvanizing the pipes by applying a zinc layer. These coatings act as barriers against moisture and other corrosive elements, ensuring the longevity and durability of the steel pipes.

- Q: What kind of argon arc welding wire is used for 16Mn steel pipe?

- JB/T4709 recommends H10MnSi, but H10MnSi allows a lower value of strength of 430MPa, which does not match the parent material. I think American Standard is selected according to the selection of welding wire ER70S-6 GB ER50-6 wire can guarantee the equivalent strength of parent materials, and Si, Mn content can also guarantee the deoxidation effect, the weld joint is not easy to produce pores.

- Q: How are steel pipes protected against soil movement or settlement?

- Various methods can be employed to safeguard steel pipes against soil movement or settlement. One prevalent approach involves the utilization of protective coatings on the pipes, which act as a barrier between the steel and the soil. By preventing direct contact and reducing the chance of corrosion, these coatings offer effective protection. Epoxy, polyethylene, and zinc are among the coatings commonly employed for this purpose. Another method entails the implementation of cathodic protection. This technique involves the installation of sacrificial anodes along the pipeline. These anodes corrode instead of the steel pipes, thus shielding them from potential harm caused by soil movement or settlement. Furthermore, ensuring proper design and installation techniques is crucial for protecting steel pipes in these scenarios. Engineers must take into account factors such as soil composition, slope stability, and the likelihood of ground movement when designing the pipeline route. Additionally, employing appropriate trenching and bedding techniques guarantees adequate support and protection against settlement. Regular inspection and maintenance play a crucial role in protecting steel pipes against soil movement or settlement. By monitoring the condition of the pipeline, including the protective coatings and cathodic protection systems, potential issues can be identified promptly, allowing for timely repairs or replacements. In conclusion, a combination of protective coatings, cathodic protection, proper design and installation techniques, and regular maintenance effectively safeguards steel pipes from soil movement or settlement.

- Q: What are the different types of steel pipe supports for seismic applications?

- There are several types of steel pipe supports used for seismic applications, including rigid supports, sway braces, and spring hangers. Rigid supports provide fixed support to the piping system, while sway braces are designed to absorb and redirect seismic energy. Spring hangers, on the other hand, are used to isolate and dampen vibrations caused by seismic activity. These different types of supports are selected based on the specific requirements and characteristics of the piping system and the seismic zone in which it is located.

Send your message to us

Steel pipe for carbon seamless ,10#-45#, cnbm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords