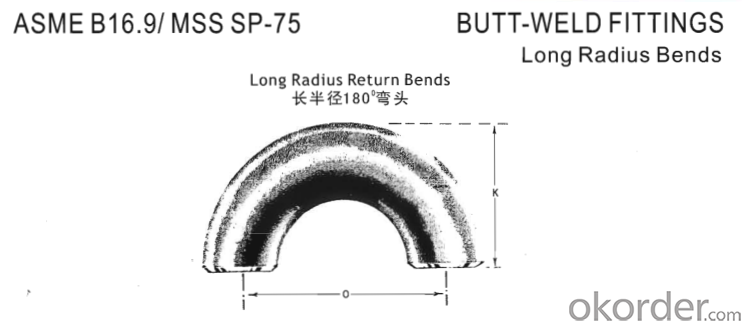

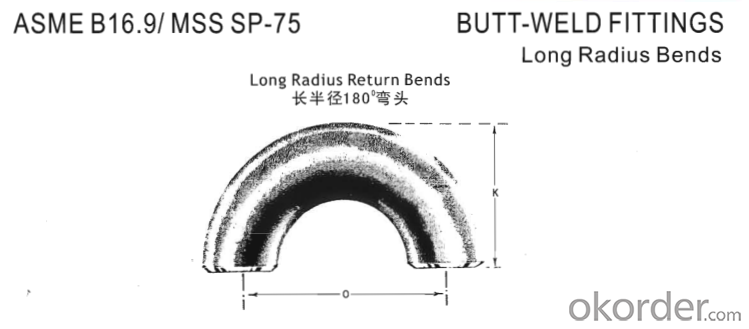

Steel Pipe Fittings Butt-Welding 180° Long Radius Bends

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

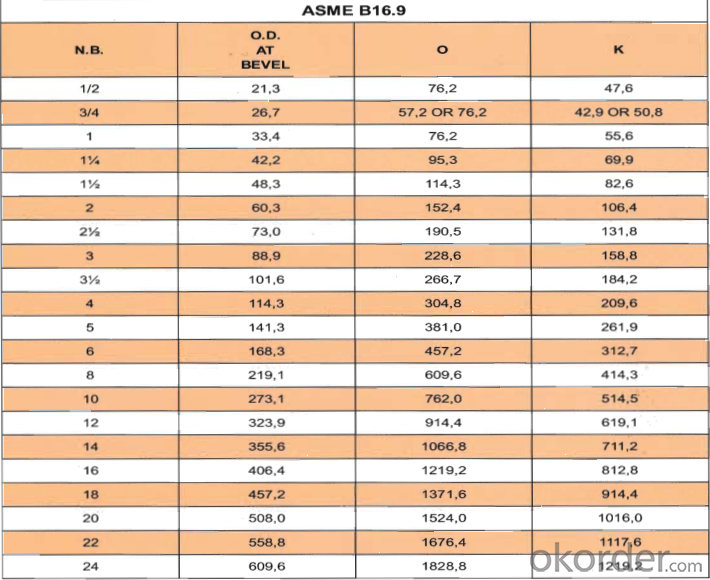

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

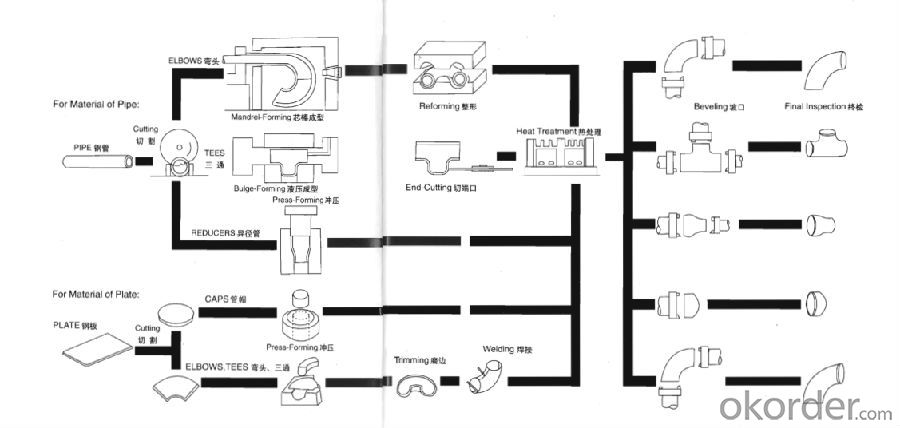

Manufacturing method and process:

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

180° Long radius bends:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q: I need to know an example of a problem astronauts faced in space preferably 2 examples but one will do. For example, to product the international space station requires a large amount of money. The solution was that by pooling together money, countries are able to achieve more than they could by themselves.

- Sharkbite connectors are the easiest connectors, you just push on. Good luck

- Q: Its said the highest risk of death in a aircrash is fire/smoke. why dont airlines supply fire/smoke blankets?

- It will work best on porous surfaces like wood. It won't work well on plastic. Read the label for applications

- Q: My 4 year old son (yes, he's too smart for his own good) locked my bedroom door, and tried to fix it by using his daddy's screwdriver and taking the doorknob off. The problem is the locking mechanism is still stuck in the door. How do I get it out without breaking the door down?

- Pipes are typically connected by welding, using threaded connections (of threaded fittings) or flanged fittings. Some connections are made using grooved fittings like Victaulic couplings. Tubing can be welded but the most common connection is a soldered slip on fitting or a fitting made specifically for tubing. Some such fitting are flared, others use a ferrol (sp?) or an o-ring or similar elastomer gasket.

- Q: Surely there is a lot of infrared light (black body and other) around at all times, how does the sensor differentiate this ambient light from the remote signal? Also, how is it that I don't need to point my remote directly at the sensor, I can have the remote in a bookshelf pointed away from the sensor and the remote still works. Are most materials highly reflective at these wavelengths?

- The larger the pipe the lower the losses. Thus it becomes an economic decision. The pipe and fittings will need to withstand significant pressure (well over 400 psi) with a 340 m head. Since your flow rate will be around 140 GPM I would suggest calculating the loss in a 3 inch pipe then determine if the extra cost of larger pipe offsets the added power required. Remember, the 37 hp assumes no losses (very large pipe).

- Q: From this list pick your top 10 favorite toys.AtariBaby AliveBalsa Wood Rubber Band AirplanesBarbieBarrel O' MonkeysBicycleBattleshipBB gunsBig Wheel / The Green MachineCabbage Patch KidsCandylandCare BearsChutes LaddersClueColorformsConnect FourCrayola CrayonsDominoesEasy-Bake OvenErector SetEtch A SketchFrisbeeG.I. JoeGameboyGreen plastic army menGumbyHe-Man and the Masters of the UniverseHula HoopHungry Hungry HipposJem and the HologramsJigsaw PuzzlesJump RopeKer PlunkLEGOLifeLincoln LogsLionel TrainsLite BriteLittle Golden BooksMadlibsMagic 8 BallMatchbox CarsMemoryMicro MachinesMonopolyMouseTrapMr. Potato HeadMy BuddyMy Little Pony NerfNintendoOperationOuija BoardPictionaryPlay DohPong Pound PuppiesRadio FlyerRaggedy Ann AndyRainbow BrightRemote Control CarsRock'em Sock'em RobotsRoller SkatesRubik's CubeScrabbleSea MonkeysSee 'n SaySee 'n SayShrinky DinksSilly Putty

- Some locks have security measures built into the design that prevents if from being carded. If you have a normally keyed lock you have many options. You might look to the hinges, an open window, brute force, or drill out the lock. There are more subtle methods that are less appropriate for an open forum.

- Q: Now that NBC fired that liar Brian Williams, should FOX follow suit and fire its entire lying broadcast staff?

- I have a suggestion but first let me shoot down some of the other idea's with the fact that in cold weather you ALWAYS need access to pipes and fittings. Heat tape-no, the electrical in heat tape goes bad and you will have no easy way to repair. Crawlspace- even if heated, you said there will be no access Ceiling running down- no, there is no heat in the ceiling and the lines would need to be exposed in the bathroom. Cold air return-maybe but again, no access I'm assuming this schoolhouse has a basement, most do, and your best option would be to build a secondary partition wall on the same wall as the addition to hide the plumbing and run it into from the basement. Essentially just poking through the now exterior wall and the new addition wall from inside the new fake exterior wall . It sounds like you need a H C for the washer, a H C for a vanity sink and a C for the toilet? Obviously the best thing would be to make as few penetrations as possible so use 3/4 copper for the sink, run flex hose or tubing for toilet and run two exposed lines from the vanity THROUGH(vanity) the side onto the wall(exposed) for the washer. I'm kind of guessing here as I'm not able to see the layout. If you're willing to make 4 penetrationsgo for it. The toilet only needs to be hose or tubing, make sure you put a separate valve in for it. The drains shouldn't matter, they are drains. As long as the traps are in a warm area and the lines are pitched well. Old houses suck. ADDITION existing exterior wall Plumbing ( H 0 C 0 H 0 C 0 ) from basement __newwall_____________________________

- Q: I work at a fire hydrant factory. I am having trouble finding a parking space near the building its very frustrating. I have to walk really far to get to the door. What should I do? Should I tell my boos about my problem?

- lol i don't get the joke but i think the situation is hilarious. personally, i would wait till after to make the joke but it wouldn't offend me if someone made a joke right away. i like people with a good sense of humor.

- Q: I am wondering what everyone prefers. I am new to working with all of this. I want to be able to do collage pendants. I have done some research so I kind of know what I can and can't use with the different products. Like obviously nothing plastic with the Amazing Glaze because it will melt. But it says with the Amazing Glaze it will be slightly yellow after drying. How bad is it? I am using antique gold and copper plated pewter pendants. So a little yellowing would be ok, but I don't want anything to look dirty. Ice resin is nice but VERY expensive. A little advice would be fantastic!! Thanks everyone!

- I would go with a bersa thunder .380+ (regular thunder is single stack + is double stack or high capacity). It holds I think 14 or 15 rounds of .380, isn't extremely heavy, and is relatively inexpensive for the quality you get. Its just the type of gun that you can rely on while still not being super concerned about it getting handled a lot or bounced around in the glove box. Also, .380 seems to be generally more available than 9mm at the moment so that my be a good choice. Overall, i think the thunder .380+ more than meets your requirements. If you live in a state that allows it, look into getting your concealed handgun license. I think you will find it much more useful if its on your person while you're in the car rather than the glovebox which may be hard to reach in a pinch (that's probably why you legally have to keep it there with no ccw) . I say that from personal experience running drills seated in the car with an airsoft pistol with my buddy as the assailant. he got me every time with the gun in the glove box.

- Q: You know the inexpensive, 9 volt battery operated smoke detectors. Should they be replaced on a regular basis? When I push the test button the alarm does sound, but should you still replace them every once in a while?

- make the threads and drill the stainless the size as needed to accept the copper pipe the fittings are not necessary if you do that you may have to braze the copper elbow to mate an elbow or some type of fitting to accommodate the column .. instead of buying all that brazing equipment find a welder that will do those short jobs take you fittings to the welder [[ it costs less for you to go to his shop ]] . enjoy the spirits [[ you will have to give it away as the sale of the moon-shine is against the laws and ATF will not like you .

- Q: I have to cite the line from this scene: 'Boo Radley. You were so busy looking at the fire you didn’t know it when he put the blanket around you.'I know that it's in chapter 8 since I found an online pdf copy of the book, but the copy doesn't have page numbers accurate to the paper copy. This is the part where after the fire on Miss Maudie's house she realizes that the blanket isn't hers and was put on her by Boo Radley while she was distracted by said fire. Paperback or eBook page citation is fine

- That's a great idea turn of the alarm and leave then when your family is robbed a murdered they will just consider you a suspect

Send your message to us

Steel Pipe Fittings Butt-Welding 180° Long Radius Bends

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords