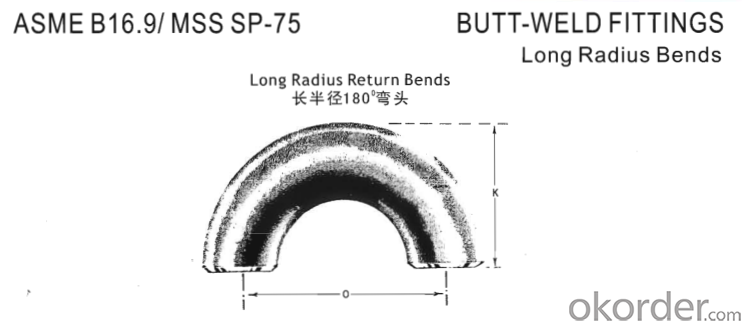

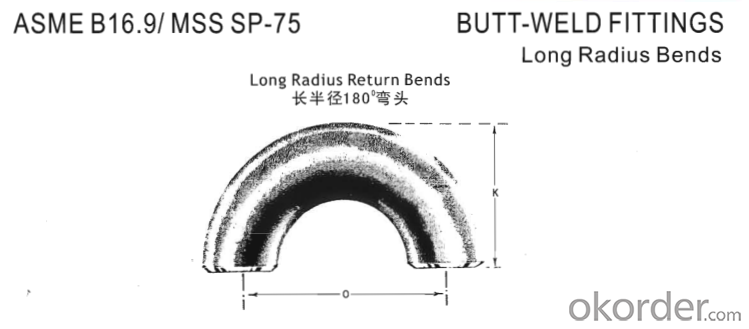

Steel Pipe Fittings Butt-Welding 180° Long Radius Return Bends

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

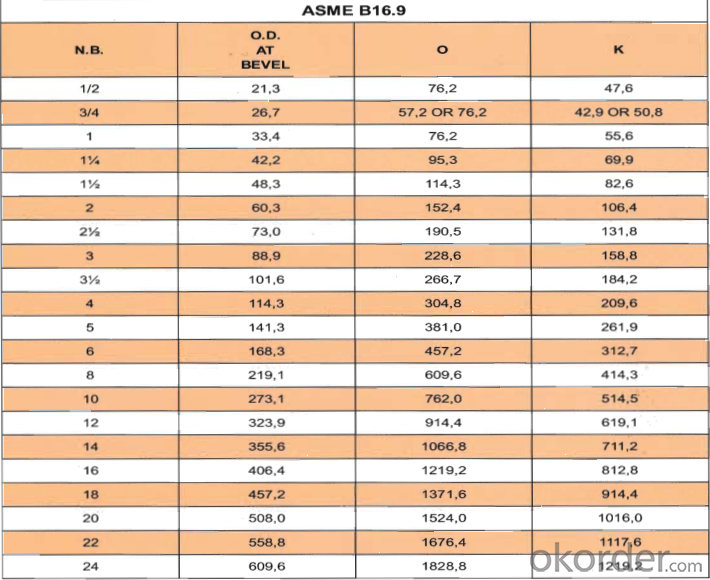

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

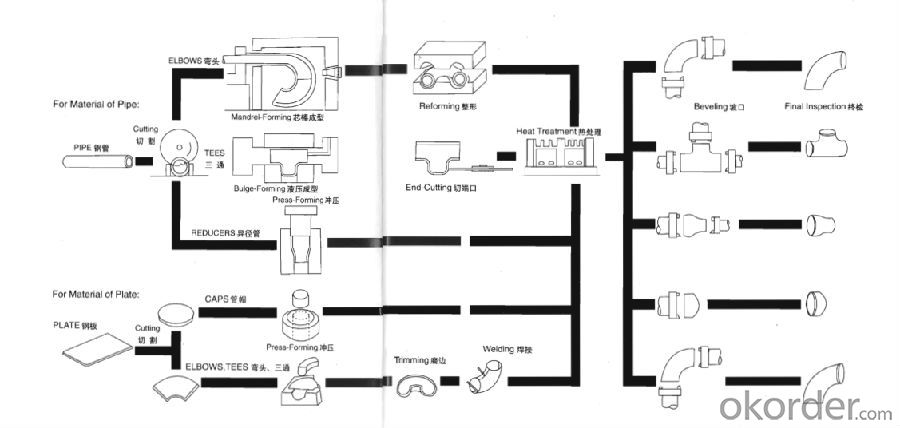

Manufacturing method and process:

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

180° Long radius bends:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q: Since they are faces and they go through the crowds during entrances will they give them a high five or a hand shake?

- I would go with disposable ones. I think if you get reusable ones they're much harder to clean. As for the coupler, you don't have to but if you decide to change the decorating tip on a certain bag of icing, you really cant because the coupler holds the decorating tip so if you want to change it, you just twist it off and apply a new one. I don't have couplers, but i guess its Okay. Just make sure you have the right bag of frosting with the right tip that way you don't make a mistake. Hope i helped :] Good Luck with your cake! :)

- Q: I would like to know where to find on the Web a bicycle helmet either with a built-in face shield (covering the actual eyes and face, not just a peak like the brim of a baseball cap), or a separate face shield that you can attach to a helmet to cover your eyes and face.Try not to limit your focus to visors on the time trial style bicycle helmets. No references to motorcycle-only helmets please! I am referring to bicycle helmets.Please link to pictures!

- These fittings come in numerous materials and pressure ratings. You need to specify what exactly you are interested in. You can then do a web search for the information you need.

- Q: I wonder if somebody could tell me how CO2 working as a fire extinguisher, regarding that it is full of oxygen?Or, is it possible that there are is some type of substance that is not possible to extinct with CO2.Is it possible that CO2 make an opposite reaction and enlarge fire?

- Pipe dope (joint compound) does not normally dry out. After it is applied it remains soft and pliable, although with time it will form a crusted surface. The pipe dope is used to form a better seal between the threads of the pipe and the fittings. As the pipe and the fittings change temperatures, the materials will expand and contract. If the pipe dope dried out it would crack and begin to leak over time. By remaining pliable it maintains the seal and prevents leakage.

- Q: Outside the wire (wire) of what the standard joint size

- External thread type metal hose jointStructure and characteristics:The outer threaded end type metal hose joint is an extension of the JB/GQ0552-83 metal joint;

- Q: Do you need adhesive for the sleeve joint of PVC wire pipe?

- It is, in theory, but very rarely used. Wiring can be done without adhesive.

- Q: What do you mean by "s" in the standard of pipe joint?

- Pointing to the nut s generally have a value, is a relatively flat nut two distance, that is the size of the wrench or view "Satisfaction, please adopt

- Q: in my assignment im asked to explain about the difficulties and misuses of lightning rods, ive looked everywhere on the net for them but im not finding

- If you have polybutylene pipe it is recommended that you change the pipe to either copper or PVC. PB has a history of failures which can cause major water damage. PB pipe has been the subject of many class action law suits and your insurance may not cover water damage caused by PB pipe failure.

- Q: i need it painted my schools colors before i can use it. please help

- You dont have to do any of extra work. Just remove the fuel filter and dont panic if gas come out. Its come only little bit then its stop. Then put new one in it.

- Q: Until what age is a Dalmatian (dog) Stud fertile? We have a pair of dalmatians but the female can't conceive.

- There are hundreds of different technologies a deaf person benefits from using - what do you need it for?

- Q: Very confused about the pipe fittings and pipe joints, I can't make out their differences. I'd like to ask you something!

- The task is accomplished by the joint body, one end of which is connected to the pipe joint and the other end connected to the device

Send your message to us

Steel Pipe Fittings Butt-Welding 180° Long Radius Return Bends

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords