Steel Coupler Rebar Steel from Tianjin China in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Couplers Rebars Steel Tube Made in China

1.Description of Steel Couplers Rebars Steel Tube Made in China:

Lapped joints are not always an appropriate means of connecting rebar. The use of Steel Rebar Couplers can simplify the design and construction of reinforced concrete and reduce the amount of reinforcement required.

The threaded steel coupler system is designed as a threaded reinforcement connection with 100% load transmission. The steel coupler rebar connection system is suitable for both static and dynamic load transmission in construction joints.

The coupler is designed as a threaded reinforcement connection for formed construction joints. Reinforcement work is normally carried out on both sides of the construction joint using lap joints or one side is anchored. The bar lengths are based on the structural analysis requirements of the building component and are calculated from anchorage and lap lengths.

2.Advantages of Steel Couplers Rebars Steel Tube Made in China:

Advantages of Cut and Bend Services

Rebars are cut and bent to exact specifications, ensuring precision and consistency.

Cut and bend reinforcement bars do conform to BS 8666.

Material wastage is controlled and reduced.

Lesser on-site labour is required.

Better utilisation of on-site space, logistics and reduction of inventory on-site.

In-house processes and procedures that ensure traceability down to the order level

Weather independent

The coupler system provides the opportunity to connect rebars quickly, easily and cost effectively, even when large rebar diameters are used. This makes the steel coupler rebar range a logical extension to our rebendable CNBM reinforcement continuity system for rebars over 12 mm.

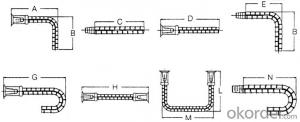

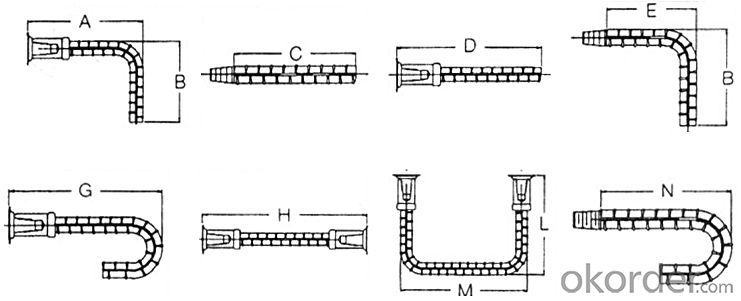

3.Available sizes of Steel Couplers Rebars Steel Tube Made in China:

14mm,16mm,18mm,20mm,22mmm,25mm,28mm,32mm,36mm,40mm

4.Delivery:

Delivery Term: FOB / CFR / CIF available.

Delivery Time: 15 days or less after order confirmed.

5.Why choose us?

Technical Expertise

Experienced Management

Stringent Quality Control

Exemplary Service

On-Time Delivery

Wide Product Range

Competitive Pricing

Huge branch network capable of catering worldwide

6.FAQ

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

- Q: I'm gonna be getting piercings this weekend, so i know im already getting my nose. but i want to get my ear. like barbell? so what's the difference between Scaffold and Industrial?

- They're the same thing. Different places call them different things.

- Q: In the construction of steel pipe scaffolding steel pipe and steel stamping fastener usage ratio is how much?

- Generally 200 tons of steel pipe with fasteners, and fasteners are generally divided into three kinds: right angle fasteners, connecting fasteners, rotating fasteners

- Q: What are the requirements for the construction of the scaffold eye in the building?

- SelectionThe project uses 48 mm, 3.5mm wall thickness steel pipe and the corresponding fasteners, dense mesh safety net, big eyes, etc.. Among them, the specification of the steel pipe is from 0.5m to 6m, and the fastener mainly has a rotating shaft, a cross and a joint fastener. Bowl buckle scaffold also uses Phi 48, 3.5 wall thickness of steel pipe and the corresponding fasteners, mainly with 1 x 1.0m, 1.2 x 1.2m, 1.5 x 1.5m and other specifications. Foot board mainly 2M and 3M two.

- Q: i have now got lumps on my scaffolding and i have searched and it seems to be normal.. i just want to know how to get rid? any ideas? :)

- A scaffold piercing should not be done with a single long bar. Go back to your piercer, or to another one and ask them to change it to two short bars, this will take the pressure off the tissue. Then you should buy some cotton cosmetic pads. Fill up a mug with boiling water from the kettle, soak a cotton pad in the water, squeeze out most of the water but not all of it, have it as hot as you can stand and hold it onto the lump. The lump is likely filled with lymph and this will encourage it to drain. Do this for about two weeks. If the lump still hasn't gone away either go back to the piercer or go see a doctor. To the person that said it shouldn't be done with the two shorter bars. Yes, I know many people who have had it done with one bar and have been fine, but I know plenty of people with horror stories. My ear could not cope with the one bar and wasn't draining properly even with regular sea salt soaks. One of my piercings has migrated slightly but I'm confident that my piercer will be able to put my long bar back in for me.

- Q: On Wednesday day I'm planning to get this done (the top piercing). I've been thinking about it for a while now really want it.What problems can I have with this piercing?How long does it take to heal ect?Thanks =)

- i've not had scaffolding but i've got a wide range of cartilage piercings and they take about 12weeks to heal... i would just say be careful not to catch it and keep it clean. good luck :)

- Q: What does my earth science teacher mean when he says to do a powerpoint with Link Scaffolding,how d u do it?

- Link Scaffolding = A search found no answer. - Ask teacher to clarify.

- Q: In the Scarlet Letter, when Dimmesdale asks Hester who Chillingworth really is, why does she keep her oath to him of not revealing that he is her husband? Guilt? Morals? Thanks

- Because she owes him since she cheated on him.

- Q: So im a guyAnd I might get oneAnyone had one before/got one?Any advice?How much do they normaly cost?if you answer this i will love you forever :)

- My industrial was the biggest nightmare piercing I've ever had. I just retired it a few weeks or so ago after waiting for it to heal for 13 months. They usually take between 6 and 12 months to heal. It never healed completely. I got keloids on the inside and outside of both holes and they looked absolutely terrible. I was actually embarrassed when people asked to see my piercing. I couldn't sleep or use the phone or use headphones on that side of my head. Changing the jewelry to titanium only made it worse (and titanium usually does wonders in my piercings). It was the most finicky and miserable piercing I have ever had. Mine was not done with one needle. That is an improper piercing technique. The second hole does hurt like heck, though. Also, don't over-clean it. Twice a day is sufficient. Sea salt soaks are amazing, too!

- Q: I'm interested in a scaffold career in the oil rigs in the north sea

- Sorry if I'm not serious, but go to Hong Kong as there they do scaffolding made of bamboo and 170 floors high ,2000mtrs above the sea level... Now that is serious...

- Q: hi, ive had my scaffolding for a little over a month now, and one of the holes has started going really weird. on the top, its swollen and sore on one side, and on the bottom, its the same but on the opposite side. not sure if its infected ir being rejected by ear, which ive heard can happen. i would like to keep it in if possible,as i love it. any help welcomed :) thanks xx

- Normally if there is an infection it is very very sore, red, warm to the touch, and secretes yellow or green pus. It sounds like you might also be possibly forming a keloid, but most likely it is just irritated. Continue with your sea salt soaks (hopefully thats what your doing) and go down to your piercer and have them check it out if you get too worried about it.

Send your message to us

Steel Coupler Rebar Steel from Tianjin China in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords