Glass Wool Steam Pipe Insulation Energy Saving Silica Aerogel Thermal Insulation Blanket

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

Aerogel Insulation Felts

Using special nanotechnology, It combines a silica aerogel with reinforcing fibers to deliver very low thermal conductivity, low density and good flexibility in an environmentally safe product. It provides excellent properties of waterproof, sound absorption and shock absorption. It is an alternative to the common, environment unfriendly, inferior insulation products, such as PU, asbestos insulation felt, silicate fibers, etc.

2.Specifications

1.Superior Thermal Performance

2.Long service life

3.Environmentally Safe

4.Sound resistance

3. Advantages

(1).Superior Thermal Performance

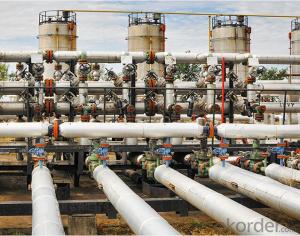

Low and ultra-low temperature equipment and piping applications

Petrochemical, power equipment applications

Various types of industrial furnaces, kilns and equipment insulation

Excellent insulation properties, thermal conductivity at room temperature can reach 33% ~ 50% of the traditional materials, high temperature is only 10 ~ 20%

Saving material and space; under the same conditions, this materials (thickness) can save more than 70%, greatly reducing transportation costs

(2). Physically Robust:

It has flexibility and high tensile strength, resisting stretching and stress from linear contraction when temperature changes.

(3). Environmentally Safe:

Composed of inorganic materials, it contains no hazard. Stripping little chloridionm will cause no corrosion to the equipments and pipes.

Low and ultra-low temperature equipment and piping applications

Petrochemical, power equipment applications

(4). Easy to Install

Extremely low density (200kg/m3) contributes to easy-to-cut and easy-to-install.

4. Technical Standard

Property | Unit | Techicial Standard | |

(refractoriness) | ---- | A Grade | |

(Density) | kg/m3 | <220< span=""> | |

(Lyophobic) | % | >99 | |

Thermal Conductivity | 25℃ | W/(m·K) | ≤0.023 |

70℃ | ≤0.029 | ||

200℃ | ≤0.036 | ||

300℃ | ≤0.045 | ||

400℃ | ≤0.056 | ||

5. Application

Oil pipe, steam pipe, refrigerator interlining, oil tank, central airconditioning pipe, chemical pipe with the requirement of fire resistance, vehicle thermal insulation, national defence, military industry, heat supply pipelines in city insulation, biological medicine pipes and equipment and so on.

- Q: How to conduct thermal insulation construction of external wall glass wool?

- Construction recommendations: Installing metal frameworks in the floor and in their corresponding roof, trying to ensure that the framework should be perpendicular to the floor; erecting metal framework in the location apart 60cm from the metal frameworks that have been placed; pasting gypsum board on one side of the frameworks and fix it to the frameworks; putting glass wool in the gap of frameworks; pasting gypsum board on the other side of the frameworks.

- Q: Behind the wall at the head of bedroom is an elevator, but how can indulate sound? Waht do you think if install silicic acid board of 12 centimeters plus glass wool and splint fo 9 centimeters and then nail soft package background in the rear?

- 1, It is advisable to buy another house because this case autually attirbutes to serious defect of the housing design. 2, You can try to change the bed to the opposite direction. 3, If adopted sound proof wall, you can refer to the pictures I offered. 4, Using board of 9cm can effectivley reduce low frequency noise of elevator.

- Q: What is the difference between the glass fiber and glass wool?

- Fiberglass is an excellent inorganic non-metallic material. There are many kinds of glass fibers whose advantages are good insulation, heat resistance, corrosion resistance, high mechanical strength, and the drawbacks are brittle and poor wear resistance. Glass wool, a man-made inorganic fiber, belongs to a kind of glass fiber. It is a spongiform material made through fibration of melten glass. It is an inorganic fiber whose chemical components belong to glass, having good formability, low bulk density, low thermal conductivity, good thermal insulation and sound absorption, corrosion resistance and chemical stability.

- Q: What are the purposes of centrifugal glass wool?

- Glass wool felts, sound-absorbing cotton felts are an ideal sound absorption and thermal insulation materials which are widely used in walls, ship engine room insulation; computer rooms, cold storages with constant temperature; various generator rooms, pump rooms noise reduction; stereo cabinets, audio adjustments, etc. Function: sound absorption and insulation, as well as thermal insulation of walls.

- Q: What is the difference between quartz wool and glass wool?

- Hello! I'm glad to answer your question! Glass wool is made by natural minerals such as quartz, dolomite, feldspar, limestone coupled with soda ash, borax and other auxiliary materials ... Glass wool is a fine fibrous material through drawing, blowing or swing of external force in melting state. Glass wool is an inorganic fiber. It has the following basic characteristics: ① It has good thermal insulation property at high and low temperatures. ② It is noncombustible without producing harmful gases, so it is designated as "legal non-combustible material" by various countries. ③ It has uniformly elastic restoring force. ④ Its moisture absorption rate is small under humid conditions. ⑤ Its coefficient of linear expansion is small. ⑥ It has low aging rate, able to remain the original performance after long-term use. ⑦ It has good machinability. Asbestos product is produced through the process that thining slate fibers by chemical beam to make them become slurry structure, and then sizing it at high temperatures. This product is characterized by lowest aging, non-degenerating, poisonless and tasteless, light weight and low thermal conductivity, etc. In addition, it is easy to construction, able to be cut freely and packaged based on types without irritating skin and wear and tear in construction and other advantages. Hope it will help you.

- Q: How effective is fireproofing glass fiber cotton?

- It will be scortched if it directly contact with flame. Usually the thermal insulation and heat perservation performance is good.gypsum board, gypsum fiber boards, cement particle board, mineral wool sound-absorbing panels, glass wool decorative sound-absorbing board, perlite decorative sound-absorbing board, flame retardant plywood, flame retardant fiberboard with medium density, rock wool decorative panels, flame retardant wood, aluminum foil,

- Q: Are there any differences between rubber and plastic thermal insulation materials and glass wool thermal insulation materials? Which one is better, please tell me more about it.

- Rubber and plastic materials have a good thermal insulation performance(thermal insulation equipment medium has a lower temperature), the fire?rating of glass wool is high(insulation equipment medium has a low temperature), rubber and plastic materials are a little bit more expensive than glass wool materials.

- Q: Is the centrifugal glass wool board suitable for home use?

- Glass wool board is strictly tested by the state, and only through the ability to sell this material, you can use, rest assured

- Q: Is centrifugal glass wool or rubber and plastic insualtion board better for air-conditioning air duct insualtion?

- Glass wool is cheaper. Feel free to ask me more. the answer is provided by the Hebei Chengxin Chemical Building. Welcomed the consultation, if satisfied please adopt. Use rubber and plastic more.

- Q: Does mineral wool, rock wool and glass wool board refer to the same kind of board?

- Rock wool is the board made by silk sprayed by basalt, gass wool is the board made by the technologies of broken glass melting and injection. there are many kinds of the heat preservation materials, every different word represents different products.

Send your message to us

Glass Wool Steam Pipe Insulation Energy Saving Silica Aerogel Thermal Insulation Blanket

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords