Stainless steel round bar Q234 for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

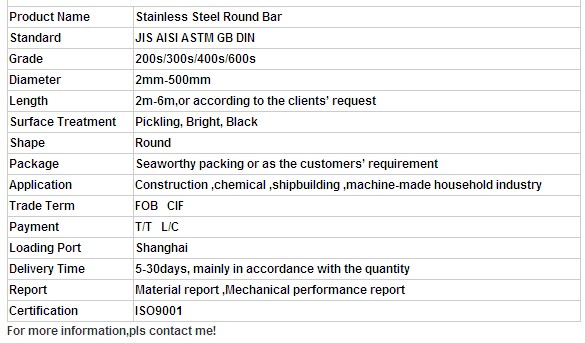

OKorder is offering Stainless steel round bar Q234 for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Stainless steel round bar Q234 for construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Stainless steel round bar Q234 for construction are durable, strong, and resist corrosion.

Main Product Features:

stainless steel round bar

1.Specification:12-300mm

2.Material:304 316

3.Length:standard 6m

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: What are the weight calculations for steel round bars?

- The weight calculations for steel round bars depend on the diameter and length of the bar. The formula used to calculate the weight is weight = volume × density, where volume = π × (diameter/2)² × length and density = 7.85 g/cm³.

- Q: Can steel round bars be heat treated?

- Yes, it is possible to heat treat steel round bars. Heat treatment involves controlled heating and cooling of the steel to alter its physical and mechanical properties. Various heat treatment processes can be used on steel round bars, including annealing, normalizing, quenching, and tempering. Annealing is a heat treatment method where the steel is heated to a specific temperature and held there for a certain period of time. It is then slowly cooled. This process is used to soften the steel, improve its machinability, and reduce internal stresses. Normalizing is similar to annealing, but the cooling is done in air. It is often employed to refine the grain structure of the steel and enhance its overall strength and toughness. Quenching is a rapid cooling process where the steel round bars are immersed in a quenching medium, such as oil or water, to cool them quickly. This process increases the hardness and strength of the steel. However, it also makes the steel more brittle. Therefore, it is often followed by tempering to reduce brittleness and improve toughness. Tempering involves reheating the hardened steel to a specific temperature and holding it there for a certain period of time. It is then slowly cooled. This process helps to reduce the hardness and brittleness caused by quenching, while still maintaining a desirable level of strength and toughness. In summary, heat treatment is a versatile process that can be applied to steel round bars to achieve a wide range of desired properties, such as hardness, strength, toughness, and machinability.

- Q: What are the safety precautions when handling steel round bars?

- To minimize the chance of accidents or injuries, it is important to adhere to several safety precautions when dealing with steel round bars. 1. Personal Protective Equipment (PPE) should always be worn. Safety goggles, gloves, steel-toed boots, and a hard hat are essential in safeguarding against potential hazards like flying debris, sharp edges, and heavy objects. 2. Proper lifting and carrying techniques are crucial. Due to the weight and bulkiness of steel round bars, it is vital to employ correct lifting methods to prevent strain or injury. Lift with your legs, maintain a straight back, and avoid twisting or jerking movements. If the bars are too heavy, seek assistance or employ mechanical aids like forklifts or cranes. 3. Ensure secure storage and stacking. Properly securing and organizing steel round bars when storing or stacking them is imperative. Use appropriate storage racks or A-frames to prevent tipping or falling, which could result in severe injuries. When stacking multiple bars, employ spacers or shims to maintain stability. 4. Be cautious of sharp edges. Steel round bars might possess sharp edges or burrs, necessitating care when handling. Wearing gloves is advised to protect your hands, and avoid dragging or sliding the bars to prevent cuts or abrasions. 5. Employ proper handling techniques. Maintain a firm grip when moving steel round bars and be aware of your surroundings. Do not swing or throw the bars, as they may strike someone or cause damage. Instead, walk slowly and steadily, ensuring clear pathways and ample space for maneuvering. 6. Inspect for defects. Prior to using steel round bars, examine them for any defects or damage that could compromise their structural integrity. Look for cracks, dents, or deformities. If any issues are detected, refrain from using the bars and report them to a supervisor or quality control personnel. 7. Observe fire safety measures. Steel round bars are highly flammable when exposed to extreme heat or sparks. Hence, avoid working near open flames or hot work areas. Keep fire extinguishers nearby and ensure that everyone is trained in fire safety protocols. By adhering to these safety precautions, the risks associated with handling steel round bars can be significantly minimized, creating a safer work environment.

- Q: What is the difference between a hot rolled and a cold drawn steel round bar?

- The main difference between a hot rolled and a cold drawn steel round bar lies in their production process and resulting characteristics. Hot rolled steel round bars are produced by heating a billet or ingot to a high temperature and then shaping it into the desired form, typically through rolling. This process results in a rough, scaled surface with rounded edges. Hot rolling allows for larger sizes and quantities to be produced quickly and efficiently. The steel is less precise in terms of dimensions and has a lower surface finish quality compared to cold drawn steel. On the other hand, cold drawn steel round bars are produced by pulling a hot rolled bar through a die at room temperature, which results in a smooth, polished surface with tighter dimensional tolerances. This process enhances the mechanical properties of the steel, such as improved strength, hardness, and dimensional accuracy. Cold drawing also provides a better surface finish and closer dimensional control compared to hot rolling. In terms of applications, hot rolled steel round bars are commonly used in construction, manufacturing, and general fabrication due to their lower cost and ease of production. They are suitable for applications where precision and surface finish are not critical factors. Cold drawn steel round bars, on the other hand, are often utilized in more demanding applications that require superior dimensional accuracy, surface finish, and mechanical properties. They are commonly used in automotive, aerospace, and machinery industries, where precision and quality are paramount. In summary, the main differences between hot rolled and cold drawn steel round bars lie in their production process, resulting surface finish, dimensional accuracy, and mechanical properties. The choice between the two depends on the specific requirements and applications of the steel.

- Q: What is the difference between a cold finished and a turned steel round bar?

- Cold finished steel round bars and turned steel round bars are utilized in various industries for different purposes. The manufacturing process and resulting properties distinguish these two types of steel bars. For a cold finished steel round bar, the production involves cold drawing or cold rolling a hot rolled steel bar. This entails passing the hot rolled bar through a series of dies at room temperature, which decreases its diameter and increases its length. Through the cold drawing process, the steel acquires specific mechanical properties, including enhanced surface finish, dimensional accuracy, and increased strength. Cold finished steel bars possess a sleek, glossy surface and are renowned for their precise tolerances and consistent size and shape. They find common usage in applications requiring precision and high-quality surface finish, such as the automotive, aerospace, and machining industries. Conversely, a turned steel round bar is created by machining a hot rolled or cold finished bar on a lathe. The bar is secured and rotated while a cutting tool eliminates material from its outer surface, resulting in the desired shape and dimensions. This turning process yields a bar with a rougher surface compared to a cold finished bar. However, it enables faster production and versatility in creating diverse shapes and sizes. Turned steel bars are frequently employed in applications where the surface finish is not crucial but machining operations are necessary, such as in the construction, engineering, and manufacturing industries. In conclusion, the distinction between a cold finished and a turned steel round bar lies in the manufacturing process and the resulting properties. Cold finished bars are produced through cold drawing or cold rolling, leading to improved dimensional accuracy, surface finish, and strength. Turned bars are machined on a lathe, providing flexibility in shape and size but with a rougher surface finish. The choice between the two depends on the specific requirements of the application, including tolerance, surface finish, strength, and machinability.

- Q: Can steel round bars be used in the textile industry?

- Limited applications exist where steel round bars can be utilized in the textile industry. Although textiles are mainly composed of natural or synthetic fibers, steel round bars can be employed in the machinery and equipment employed in textile production. These bars commonly serve as the foundation for frames, supports, and other structural components of textile machinery. For instance, steel round bars can be employed to construct the frames of looms, which are essential for fabric weaving. Additionally, they can be integrated into the fabrication of spinning machines, knitting machines, and other textile manufacturing equipment. Furthermore, steel round bars can function as a base or support for textile drying racks, storage systems, or conveyor systems. The strength and durability of steel make it an appropriate material for withstanding the rigorous demands of industrial textile production. However, it is worth noting that steel round bars are not directly incorporated into the fabric or textile products themselves.

- Q: What are the different types of steel round bar coatings used in the marine industry?

- There are several types of steel round bar coatings commonly used in the marine industry, including galvanized coatings, epoxy coatings, and corrosion-resistant coatings. These coatings help protect the steel from rust and corrosion caused by exposure to saltwater and other harsh marine environments.

- Q: How are steel round bars measured and specified?

- The diameter is utilized to measure and specify steel round bars. Typically, the diameter of a round bar is measured in millimeters or inches. The measurement is taken at the widest point of the circular cross-section. When it comes to specification, steel round bars are commonly specified by their diameter and length. For instance, a steel round bar can be specified as "25mm diameter x 3 meters length". This indicates that the bar has a diameter of 25mm and a length of 3 meters. Moreover, steel round bars can also be specified based on their tolerance, surface finish, and grade. Tolerance refers to the allowable deviation from the specified diameter. Surface finish pertains to the quality of the bar's surface, which can vary from rough to smooth. Grade signifies the quality and composition of the steel utilized to produce the round bar, such as mild steel, carbon steel, or alloy steel. Accurate measurement and specification of steel round bars are crucial to ensure that they meet the necessary dimensions and properties for a specific application.

- Q: Can steel round bars be used in the production of construction equipment?

- Yes, steel round bars can be used in the production of construction equipment. Steel round bars are commonly used in the construction industry due to their strength, durability, and versatility. They can be used to manufacture various components of construction equipment such as axles, shafts, gears, and structural supports. The high tensile strength of steel round bars ensures that the equipment can withstand heavy loads and harsh operating conditions. Additionally, the machinability and weldability of steel round bars make them suitable for fabrication processes involved in the production of construction equipment. Overall, steel round bars are a reliable and commonly used material in the construction industry for manufacturing construction equipment.

- Q: What are the different types of steel round bar alloys for improved wear resistance?

- There are several different types of steel round bar alloys that are specifically designed to improve wear resistance. These alloys are formulated to have enhanced hardness and toughness, making them suitable for applications where the material is subjected to constant friction or abrasive forces. One common alloy is tool steel, which includes variations such as H13, D2, and A2. Tool steel is known for its high hardness, excellent wear resistance, and good toughness. It is often used in applications such as molding and forming tools, cutting tools, and dies. Another alloy for improved wear resistance is stainless steel. Stainless steel round bars are corrosion-resistant and have good strength properties. They are commonly used in applications like food processing equipment, medical devices, and marine components. Abrasion-resistant steel, also known as AR steel, is another type of alloy used for improved wear resistance. AR steel is specially formulated to withstand impact and abrasion, making it ideal for applications such as mining equipment, construction machinery, and material handling systems. Manganese steel is another alloy that provides excellent wear resistance. It is commonly used in applications involving high impact and abrasive wear, such as crusher jaws, railroad crossings, and excavator buckets. Lastly, there are specialty alloys such as chrome-moly steel (chromium-molybdenum) and nickel-chromium alloys, which offer superior wear resistance in specific conditions. These alloys are often used in high-temperature applications, such as aerospace components, power generation equipment, and automotive parts. In summary, the different types of steel round bar alloys for improved wear resistance include tool steel, stainless steel, abrasion-resistant steel, manganese steel, and specialty alloys. Each alloy has its own unique properties and is suited for specific applications where wear resistance is a critical requirement.

Send your message to us

Stainless steel round bar Q234 for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords