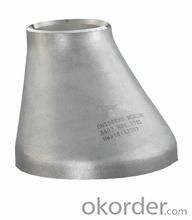

STAINLESS STEEL PIPE BUTT WELDED REDUCER 304/316 ANSI B16.9 good PRICE BEST QUALITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Package Of Stainless Steel Butt-Welded Fitting:

PACKED IN PLYWOOD CASES OR PALLETS

Painting Of Stainless Steel Butt-Welded Fitting:

ANTI-RUST OIL

Marking Of Stainless Steel Butt-Welded Fitting:

REFER TO MARKING DOCUMENT or AS PER CUSTOMER REQUEST

Shipping Marks Of Stainless Steel Butt-Welded Fitting:

EACH WOODEN BOX TWO PLASTIC SHIPPING MARKS

Specification Of Stainless Steel Butt-Welded Fitting:

Stainless Steel 90Deg LR Elbow, Tee, Reducer and Cap

Size : 1/2"-48"

Wall Thickness.: SCH10-SCH160, SGP , XS, XXS, DIN ,STD

| Name | Stainless Steel Butt-Welded Fitting |

| Size | 1/2" - 48" |

| ANGLE | 45D 90 D 180D |

| Wall thickness | Sch5-Sch160 XXS,STD,XS, SGP |

| Standard | ASME B16.9, GOST 17375-2001, DIN2605 and JIS B2311, EN10253-1 etc. |

| We can also produce according to drawing and standards provided by customers. | |

| Material | 304, 304L, 316, 316L, 304/304L, 316/316L, EN1.4301, EN1.4404 etc. |

| Packaging | Wooden Cases, wooden pallet , or carton box , or nylog bag and then in wooden cases |

| Surface Treatment | Anti-rust Oil |

| Delivery Time | 20-30 days, after received advance payment. |

| Quality | 100% Heat Treatment, No Welding repair |

| Others | 1.Special design available according to your drawing. |

| 2.anti-corrosion and high-temperature resistant with black painting | |

| 3. All the production process are made under the ISO9001:2000 strictly. | |

| 4. A conformity rate of ex-factory inspection of products. | |

| 5. we have export right , offering FOB , CNF CIF price |

STANDARD & MATERIAL GRADE

STANDARD Of Carbon Steel Butt-Welded Fitting

| Standard | Wall Thickness | Type | |

| American Standard | ASME B16.9 | S5S ~ XXS | 45D, 90D, 180D ELBOW, TEE, REDUCER, CAP, STUB END |

| ASME B16.11 | |||

| ASME B16.28 | 90D SR ELBOW | ||

| Japanese Standard | JIS B2311 | SGP ~ LG |

MATERIAL Of Stainless Steel Flange

| Stainless Steel | ||

| Material Standard | Material Grade | |

| ASTM | ASTM A182 | F304 / F304 L |

| ASTM A182 | F316/ F316L | |

| ASTM A182 | F310, F321 | |

| ASTM A182 | F321 | |

| DIN EN | DIN EN 10222-5 | EN 1.4301 |

| DIN EN 10222-5 | EN 1.4404 | |

| JIS | JIS G3214 | SUS F304 |

| JIS G3214 | SUS F304L | |

| JIS G3214 | SUS F316 | |

| JIS G3214 | SUS F316L | |

- Q: Can steel pipes be threaded?

- Yes, steel pipes can be threaded. Threading is a common process used to create screw-like ridges on the ends of the steel pipes, allowing them to be easily connected to fittings or other pipes.

- Q: Does seamless steel tube have a bend of 135 degrees?

- In engineering, it is usually marked as "45 elbow" and has no "135" mark. The angle of the elbow is acute, so there will be no more than 90 degrees elbow.Elbow is a common connecting pipe used in plumbing and heating. It is used for the connection of the bend of pipe, and is used to change the direction of pipe.

- Q: How much is 4 inches steel tube MM?

- Seamless root weight per meter: 1 mm (diameter - thickness) * wall thickness of *0.02466*1 meters is? Normal KG/M pipe length 8-11rice

- Q: Can steel pipes be used for plumbing?

- Yes, steel pipes can be used for plumbing. Steel pipes are commonly used for plumbing applications due to their strength, durability, and resistance to corrosion. However, other materials such as copper and PVC are also commonly used depending on the specific requirements and preferences of the plumbing system.

- Q: Theoretical weight of 25*25*1.5 square steel tubes

- Theoretical weight can be directly from the steel tube under the table look up, you can also press type calculation:Weight per meter =4x, wall thickness x (side length - wall thickness) x0.00785. The length of the square tube and the wall thickness are in millimeters, and the weight of each square meter is in kilograms.

- Q: What are the different types of steel pipe coatings for drinking water pipelines?

- There are several types of steel pipe coatings used for drinking water pipelines, including fusion bonded epoxy (FBE), polyurethane (PU), and polyethylene (PE). These coatings provide corrosion protection, prevent leaching of contaminants into the water, and ensure the durability of the pipes.

- Q: What is the difference between steel pipes and fiberglass pipes?

- Steel pipes are made from a durable alloy of iron and carbon, while fiberglass pipes are composed of a reinforced plastic material. The main difference is that steel pipes are stronger and more resistant to high temperatures and pressure, making them suitable for heavy-duty applications such as oil and gas pipelines. On the other hand, fiberglass pipes are lighter, corrosion-resistant, and have better thermal insulation properties, making them ideal for industries like chemical processing and wastewater treatment.

- Q: What are the advantages of using steel pipes in construction?

- There are several advantages of using steel pipes in construction. Firstly, steel pipes are highly durable and have a long lifespan, making them ideal for long-term projects. Secondly, steel pipes have a high strength-to-weight ratio, meaning they can support heavy loads without being bulky or cumbersome. Additionally, steel pipes are resistant to corrosion, which ensures their longevity and reduces maintenance costs. Moreover, steel pipes are adaptable and can be easily fabricated and customized to fit specific project requirements. Lastly, steel pipes are eco-friendly as they can be recycled, reducing waste and promoting sustainability in construction.

- Q: Do steel pipes expand or contract with temperature changes?

- When the temperature increases, steel pipes undergo expansion, while they contract when the temperature decreases. This occurrence is due to the thermal expansion and contraction characteristics of steel, which are present in most materials. When steel pipes are heated, the molecules within the metal gain energy and vibrate more intensely, causing them to separate and increase in size. On the contrary, when the temperature of the steel pipes decreases, the molecules lose energy and move closer together, resulting in a reduction or shrinking in size. It is crucial to take into consideration these thermal expansion and contraction properties of steel pipes during their design and installation, as failure to accommodate these fluctuations might result in structural damage, leaks, or other complications.

- Q: What is the difference between steel pipe and polyethylene pipe?

- Steel pipe and polyethylene pipe are two different types of materials used for plumbing and construction purposes. The main difference between these two pipes lies in their composition and characteristics. Steel pipe is made from a combination of iron and carbon, which gives it its strength and durability. It is commonly used in applications where high pressure and heavy loads are expected, such as in industrial settings or for underground gas and oil pipelines. Steel pipe is known for its resistance to corrosion and its ability to withstand extreme temperatures. On the other hand, polyethylene pipe is a type of plastic pipe made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE). It is lightweight, flexible, and easy to install, making it a popular choice for residential plumbing and irrigation systems. Polyethylene pipe is resistant to chemicals, UV rays, and abrasive materials, making it suitable for both above-ground and underground installations. Another significant difference between steel pipe and polyethylene pipe is their cost. Steel pipe generally tends to be more expensive due to the raw materials and manufacturing processes involved. Polyethylene pipe, on the other hand, is relatively affordable and cost-effective, especially for smaller-scale projects. In terms of maintenance, steel pipe requires periodic inspections and maintenance to prevent corrosion and ensure its longevity. Polyethylene pipe, on the other hand, is virtually maintenance-free due to its resistance to corrosion and chemical degradation. In summary, the main difference between steel pipe and polyethylene pipe lies in their composition, strength, durability, cost, and maintenance requirements. The choice between these two pipes depends on the specific needs of the project, taking into consideration factors such as pressure, load, budget, and environmental conditions.

Send your message to us

STAINLESS STEEL PIPE BUTT WELDED REDUCER 304/316 ANSI B16.9 good PRICE BEST QUALITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords