Stainless Steel Coil Cold Rolled 304 BA With Great Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Coil Cold Rolled 304 With Good Quality

1.Structure of Stainless Steel Coil Cold Rolled 304 With Good Quality

Cold Rolled stainless steel Coil with good quality is one of the raw material of the cold

rolled stainless steel Coil, which can be used directly in many places. Stainless Steel

(Stainless Steel) is short for acid-proof Stainless Steel, resistant to weak corrosive

medium such as air, steam, water, or with a Stainless Steel grade.

2.Main Features of Prefabricated Steel Structure High Building Project

1) Weld-ability: The purpose of the different requirement for welding performance are

different.1 Kind of tableware generally do not require the performance of welding, even

including some pot class enterprise. But the vast majority of products all need raw

materials welding performance is good, like the 2 kinds of tableware, thermos flask, steel

pipes, water heaters, water dispensers, etc.

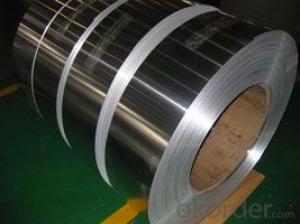

3. Stainless Steel Coil Cold Rolled 304 With Good Quality Images

4. Stainless Steel Coil Cold Rolled 304 With Good Quality Specification

The word "stainless steel" is not merely refers to a pure stainless steel, but said more than

one hundred kinds of stainless steel industry, the development of each stainless steel has

good performance in their specific applications. The key to the success of the first is to

make clear purpose, and then determine the correct material. Related to architectural

construction applications usually only six types of steel. They contain 17 ~ 22% chromium,

good steel contains nickel. Add molybdenum can further improve the atmospheric

corrosion resistance, especially containing chloride atmospheric corrosion resistance.

Stainless steel often according to the state of organization can be divided into: martensite

steel, ferritic steel, austenitic steel, austenitic (two-phase) - ferrite stainless steel and

precipitation hardening stainless steel, etc. In addition, according to ingredients can be

divided into: chromium stainless steel, chromium nickel stainless steel and chromium

manganese nitrogen stainless steel, etc.

Austenitic, ferritic duplex stainless steel The advantages of both austenitic and ferritic

stainless steel, and has the superplasticity. Austenite and ferrite The title Each accounts

for about half of the stainless steel. In the case of contain low C, Cr content was 18% ~

18%, Ni content at 3% ~ 3%. Some steel containing Mo, Cu, Si, Nb, Ti, N and other

alloying elements. This kind of steel both austenite and ferrite stainless steel, the

characteristics of compared with ferrite, plasticity and toughness is higher, no room

temperature brittleness, intergranular corrosion resistance and welding performance were

significantly increased, while maintaining a ferritic stainless steel of 475 ℃ brittleness and

high thermal conductivity, has the characteristics of superplasticity. Compared with

austenitic stainless steel, high strength and resistance to intergranular corrosion and

resistance to chloride stress corrosion is improved obviously. Duplex stainless steel has

excellent resistance to pitting corrosion performance, is also a kind of nickel and stainless

steel.

5. Applications of Stainless Steel Coil 304 With Good Quality

1. Kitchenware: tableware, cookware, Stoves…

2. Food packing: storage cans, food containers…

3. Construction: bridge, roofing, wall, decoration, bathroom accessories…

4. Precision instruments: electrical products, aerospace…

5. Others: automotive parts, machine building, chemical processing, farming…

6.FAQ of Stainless Steel Coil 304 With Good Quality

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,

is one of the large-scale professional investment casting production bases in China,

consisting of both casting foundry forging and machining factory. Annually more than 800

0 tons Precision casting and forging parts are exported to markets in Europe,America an

d Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we willprovide necessary

follow-up service assurance.

③How is the packaging and delivery?

Standard export packing (Coil: waterproof paper + protective steel ring; Circle: wooden

box), or as your requirement and the delivery term is based on the project.

④How long can we receive the product after purchase?

In the purchase of product within 20 working days, We will arrange the factory delivery as

soon as possible. The specific time of receiving is related to the state and position of

customers. Commonly 20 to 40 working days can be served.

- Q: Can stainless steel strips be used for architectural signage?

- Yes, stainless steel strips can be used for architectural signage. Stainless steel is a durable and versatile material that is often used in architectural applications due to its strength and resistance to corrosion. It can be easily formed into various shapes and sizes, making it suitable for creating signage with different designs and dimensions. Additionally, stainless steel is known for its aesthetic appeal, with its polished finish providing a sleek and modern look. This makes it a popular choice for architectural signage, as it can enhance the overall appearance of a building or space. Furthermore, stainless steel is a low-maintenance material that can withstand harsh weather conditions, ensuring that the signage remains in good condition for an extended period. Overall, stainless steel strips are a reliable and visually appealing option for architectural signage.

- Q: Why does stainless steel carry magnetism?

- If you go to the molten steel and high chromium nickel austenitic steel, tempered magnet is not stainless steel. If the molten steel in the main alloy elements is chromium, iron and carbon and a small amount of nickel (or without nickel), tempered steel is a magnet on the stainless steel, also called ferritic stainless steel martensitic stainless steel or austenitic stainless steel. In addition to the magnet is not on, ferrite, martensite stainless steel are magnetic. The nickel element in the reserves in the world is very few, the price is more expensive, therefore, high nickel content in stainless steel on the market price is higher, and the magnet suction is not at present because of austenitic stainless steel for stainless steel in the proportion is still great, so that people have a misconception of all stainless steel are non-magnetic.

- Q: How do stainless steel strips perform in the presence of caustic solutions?

- Stainless steel strips generally have excellent resistance to caustic solutions due to their high corrosion resistance properties. However, the specific performance may vary depending on the grade of stainless steel used and the concentration and temperature of the caustic solution. It is always recommended to consult the material data sheet or conduct tests to ensure compatibility with specific caustic solutions.

- Q: Can stainless steel strips be used in the production of architectural fittings?

- Yes, stainless steel strips can be used in the production of architectural fittings. Stainless steel is a popular material in the architectural industry due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel strips can be easily formed, welded, and fabricated to create a wide range of architectural fittings, including handrails, door handles, balustrades, and decorative elements. The versatility of stainless steel allows for the creation of both modern and traditional architectural designs. Additionally, stainless steel is low maintenance, making it ideal for architectural fittings that require long-lasting durability in various environments.

- Q: Are stainless steel strips suitable for oil and gas applications?

- Yes, stainless steel strips are suitable for oil and gas applications. Stainless steel offers excellent resistance to corrosion, making it highly suitable for use in oil and gas environments where exposure to corrosive substances is common. Additionally, stainless steel strips have high strength and durability, allowing them to withstand the harsh conditions and pressures often found in oil and gas operations. They also have good heat resistance and can maintain their mechanical properties at both high and low temperatures. These properties make stainless steel strips ideal for a wide range of applications in the oil and gas industry, including pipelines, storage tanks, and offshore platforms.

- Q: Can stainless steel strips be coated with protective films?

- Yes, stainless steel strips can be coated with protective films. The films serve as a barrier against scratches, corrosion, and other potential damages, preserving the surface quality and extending the lifespan of the stainless steel strips.

- Q: Can stainless steel strips be used in architectural roofing systems?

- Indeed, architectural roofing systems can incorporate stainless steel strips. Due to its durability and resistance to corrosion, stainless steel is well-suited for diverse construction applications, including roofing. One can utilize stainless steel strips as roofing panels or as components of a roofing system. This choice guarantees exceptional robustness, durability, and protection against weathering, UV radiation, and rust. Moreover, the sleek and contemporary aesthetic of stainless steel contributes to the enhancement of a building's architectural design. Nevertheless, it remains crucial to evaluate the specific requirements and conditions of the roofing project. This assessment enables the determination of the most appropriate material and gauge of stainless steel strips, ensuring optimal performance and longevity.

- Q: What is the yield strength of stainless steel strips?

- The yield strength of stainless steel strips varies depending on the specific grade and temper of the material. It typically ranges from 30,000 to 100,000 pounds per square inch (psi).

- Q: Can 111 stainless steel strips be used in nuclear power plants?

- Yes, 111 stainless steel strips can be used in nuclear power plants. Stainless steel is commonly used in nuclear power plants due to its corrosion resistance, high strength, and good mechanical properties. The specific grade of stainless steel, such as 111, may vary depending on the application and the specific requirements of the nuclear power plant. However, it is worth mentioning that stainless steel is not used in all components of a nuclear power plant, and other materials may also be used depending on the specific needs and regulations.

- Q: What are the recommended protective measures for transporting 111 stainless steel strips?

- To ensure the safety and prevent damage while transporting 111 stainless steel strips, it is crucial that certain protective measures be taken. Here are some recommended measures to consider: 1. Packaging: It is essential to package each stainless steel strip individually to avoid scratching or rubbing against each other. Plastic wrap, foam sheets, or bubble wrap can be used for added protection. 2. Load security: To prevent any movement or shifting during transportation, securely fasten the packaged stainless steel strips. Straps, ropes, or appropriate fastening materials should be used to hold the load in place. 3. Pallets or crates: If possible, transport the stainless steel strips on pallets or in crates. This helps evenly distribute the weight and provides an extra layer of protection. Ensure that the pallets or crates are in good condition and sturdy enough to support the weight. 4. Moisture avoidance: To avoid corrosion, shield the stainless steel strips from moisture during transit. Waterproof covers or tarps can be used to protect them from rain, snow, or any other form of moisture. 5. Temperature control: If extreme temperatures are involved in the transportation, it is advisable to control the temperature inside the transport vehicle. This helps minimize potential damage caused by expansion or contraction of the stainless steel strips. 6. Handling precautions: During loading and unloading, handle the stainless steel strips with care to prevent bending, denting, or other forms of damage. Appropriate lifting equipment should be used, and personnel involved in handling should receive proper training. 7. Insurance coverage: Consider obtaining insurance coverage for the transportation of the stainless steel strips to provide financial protection in case of unforeseen accidents or damages during transit. It is important to seek guidance from transportation experts or professionals experienced in handling stainless steel strips to ensure the implementation of the best protective measures. Their expertise can help minimize the risk of damage and ensure the safe transportation of the stainless steel strips.

Send your message to us

Stainless Steel Coil Cold Rolled 304 BA With Great Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords