Clean Room Cotton Swabs ST-004 CA-003

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

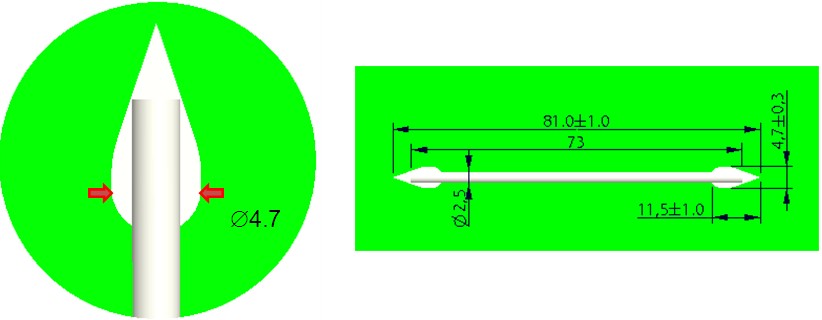

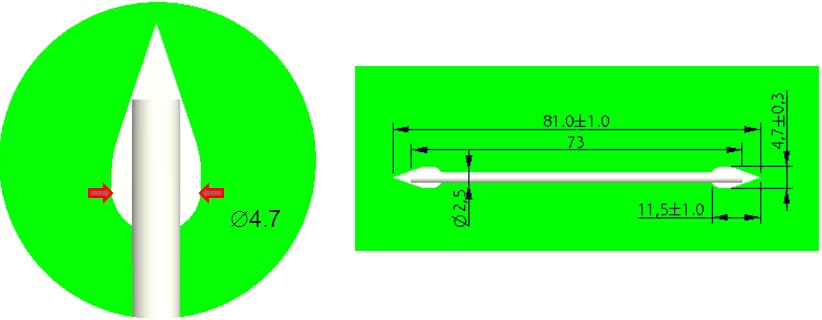

Product No.:ST-004 (CA-003)

Stick:3” Paper

Stick Diameter:2.5mmØ

Tip Diameter:4.7+/-0.3mm

Tip Length:11.5+/-1.0mm

Total Length:81.0+/-1.0mm

Packing Way:25pcs*100packs*10boxes

Carton Size:55*52*22cm

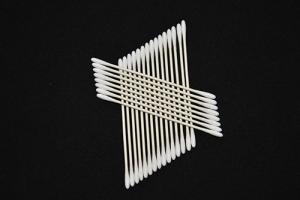

The clean room cotton buds are widely used in cleaning precise electronic components, laser, semi-conductor, optics lens, and magnetic read head etc. Our clean room cotton swabs can dip with DI Water, alcohol, IPA, and acetone solution. ST-004 is the perfect replacement of CA-003 in HUBY340 series.

- Q: What are the types of cleaning equipment

- The question you ask is unscientific, and there is no way to answer it at all At least a small class

- Q: What are the benefits of sanitation

- It's good for the equipment and it's comfortable to watch

- Q: Procter &gamble has some common cleaning equipment in the cleaning of the property

- Commercial vacuum cleaner: used for the ground, metope and other flat areas to absorb dust and dirt, the equipment that is used in the cleaning job is one of the most commonly used equipment. The vacuum cleaner starts with a strong suction force, which allows the dust to flow down the airflow into the storage and dust chamber to clean the floor. There are many different types of vacuum cleaners, which have common and powerful types of suction force. There are different types of ground dust, carpet dust, cleaning furniture and so on. There is a single vacuum cleaner and a vacuuming suction vacuum cleaner.

- Q: What is the issue of cleaning equipment? Is there a difference between industrial cleaning equipment and common equipment?

- Industrial high pressure cleaning machine: product positioning is machine equipment Industrial high pressure cleaner is designed according to the condition of industrial cleaning, generally USES a relatively low speed, forged steel crankshaft crankshaft, crosshead bearing alloy, independent lubrication system and electrical control cabinet. The main characteristics are: high reliability, high load capacity, high safety factor. The materials used in machine manufacturing are quite elegant, including manufacturing accuracy, heat treatment of materials, testing and strength tests. The highest rated working pressure of the industrial high pressure cleaning machine is much higher than the highest rated working pressure of the commercial high pressure cleaning machine. 2: under the same technical parameters (pressure flow), industrial high pressure cleaner can effectively continuously working time is more than commercial grade high pressure cleaner can effective working hours continuously.

- Q: Characteristics of cleaning equipment of cleaning equipment

- High pressure water jet cleaning mainly has the following characteristics: (1) selecting the appropriate pressure level, the water jet cleaning will not damage the base of the cleaning equipment. (2) is using ordinary tap water with a high speed washed clean, so it does not pollute the environment, anti-corrosion equipment, won't cause any mechanical damage, can also be removed with chemical cleaning of refractory or cannot dissolve the special scale; (3) after washing, the equipment and parts shall not be cleaned; (4) cleaning parts that are complex in shape and structure, which can be cleaned in a space narrow, complex, hostile and harmful environment; (5) it is easy to achieve mechanization, automation and digital control. (6) save energy, clean efficiency and low cost. Chengdu feng cleaning machine, with its strong technical force and reliable after-sales service protection, the pressure washer in the domestic many areas have a large promotion, cleaning machines are exported to overseas markets, done a good job in the technology field.

- Q: What is suitable for factory cleaning equipment

- Industrial vacuum cleaner is used to collect waste gas, dust and debris from equipment in industrial production, purify workshop environment, and no secondary pollution. High pressure cleaning machine, clean equipment oil pollution, rust stain, and some areas with small and unsanitary areas.

- Q: What cleaning equipment does the factory clean equipment need?

- Cleaning equipment as the name suggests is designed for cleaning machinery and equipment, cleaning equipment in the workplace play an effective cleaning effect, reduces the labor cost of clean cleaning equipment at the same time also improves the work efficiency and cleanness is indispensable to modern society.

- Q: It is best to wash mechanical equipment using that cleaner

- See what equipment needs to be cleaned, the current cleaning agent is nutritionally ionized, non-ionized... Principle: 1. The cleaning agent shall not be related to damage, corrosion and pollution. Effectively remove dirt; You can satisfy these two principles

- Q: How do you clean the inside of the electric oven? Can you use a wire ball or a detergent?

- First wear latex gloves, detachable parts are removed inside the oven, such as baking, chassis, and then with a neutral detergent washing, paying special attention to oil dirties is very heavy, can use special cleaning fluid, such as the kitchen cleaner to do the key parts of decontamination. Then put an old newspaper in the door of an embedded oven and brush the broken pieces of the oven out of the oven with a small brush. Outside of the inside of the oven to heat pipe and heat pipe shield must use dry cloth to wipe gently, can't use a wet cloth, so as not to affect the heating pipe insulation, leakage phenomenon of short circuit. Except for the removable part of the oven, it is not possible to scrub clean and water with water or a wet cloth. If found the heating tube and fence are dirty, with dry cloth to wipe clean, also can not change with the rough surface such as steel wire ball, clean ball cleaning tools to wipe. If you have wire or hard particles falling into the heating tube, light barbecue an unpleasant feeling of anxious burnt flavour, or cause the entire circuit short circuit, can try to use clean force strong nylon cloth is wiped a few times more. After cleaning the heating tube, you can begin to clean the outer shell of the oven and the inside bladder. The cloth in the diluent of neutral detergent slightly wet, wipe with wet wipe the body shell, dip again after cleaning, diluent, and wring dry, into the oven inside pumice, final reoccupy clear water rinse wipe dry after dry, wipe it twice.

- Q: How many kinds of cleaning equipment are there for cleaning companies?

- Ogilvy Lin cleaning cleaning tool use commonly: 2000 w vacuum suction machine, multi-function cleaning machine, polishing machine, glass scraper, with water, glass cutter, clean ball, microfiber cloth, towel (one-time), glass cleaner, clean neutral detergent, highly-effective cleaning agent, speed powder, seat belts, telescopic rod, brush, herringbone ladder, toolbox, rubber gloves and other professional tool

Send your message to us

Clean Room Cotton Swabs ST-004 CA-003

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords