Square and Round Ductile Casting Iron Manhole Cover EN124 in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 kg

- Supply Capability:

- 4100 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

1.Place of Origin: Hebei, China (Mainland)

2.Brand Name: CMAX

3.Model Number: EN124 Standard

4.Application: Construction

5.Material: Iron

6.Dimensions: OEM

7.Surface treatment: Painting

8.Process: Casting. Drilling. Threading

9.Certification: ISO9001:2008

10.Standard: EN124 Standard

11.Name: Iron Casting Parts

12.Color: Grey

13.Type: Moulding Press

14.Service: OEM Service

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

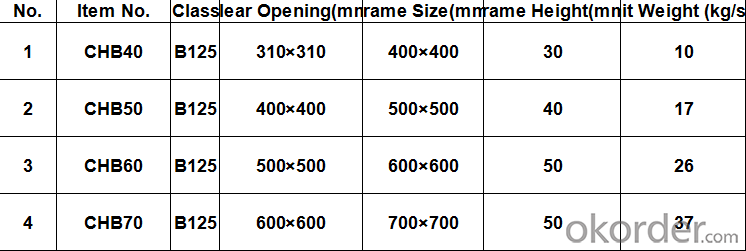

Specifications

Double triangle ductile iron manhole cover

1.Standard:ISO 9001 EN124 D400

2.Service:OEM

3.High quality

4.Made of ductile

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers. Our customer come from America, Morocco , saudi arabia, Iran , Algeria and so on

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard.

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press.Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

5. Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

6. Professional technical support with free charge.

7. After the cooperation: Any of your problem will be solved within 24 hours.

FAQ

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery

E. Good after sales service

2. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

3. How about the shipment?

A. Small quantity you can choose by air

B. Less than one container you can choose LCL shipment by sea

C. One container or more than one container you can choose FCL shipment by sea.

- Q: What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- Please consider the following points:1, batch: if the product batch is very large, casting will certainly have advantages, cost sharing will be very low. If less, it is recommended to use weldments.2. Reinforcement structure: if the structure is relatively simple, it is recommended to use welded parts, complex, preferably casting.

- Q: The casting sand is going on

- Dispersed sand inclusion is common on the surface and subcutaneous of steel castings, often concentrated on the outer surface of the upper box and the inner surface of the lower case, and a few of them are inside the cast steel parts.

- Q: What are the casting parts processing engineering?

- At present, casting processing, according to metal classification, divided into cast iron, cast steel, casting non-ferrous metal.

- Q: Casting parts have poor surface finish. What sand is used to make them?

- V casting, EPC, precision casting of the surface is good.

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- 304 stainless steel is easier to change than ordinary steel. Because the 304 heat conductivity is lower than that of the low doped steel, the temperature is even more uneven, and 20% of the non ferrous elements also make the distribution of internal and external elements more uneven, hard and soft inside. Each of these two produces greater internal stresses, resulting in a variant.

- Q: Why do casting parts have air holes?

- There are many reasons for casting porosity, mainly due to:1. smelting process is unreasonable, metal liquid absorbs more gas;2. the gas in the mold invades the metal liquid;3. from the mold is more water brush, core dry;4. the casting has poor ventilation;5. ladle tools are not dry.Wait。

- Q: Cause of choking of casting parts

- Is it boiling from the picture? Does it sound like a fire? If not, it's not choking. I feel like choking. The gas doesn't drain out

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

- Q: What are the general technical requirements for casting parts?

- Satisfy appearance quality (appearance defect, quality change, size deviation)Intrinsic quality (composition, properties, internal organization)Service performance (abrasion resistance, corrosion resistance, heat resistance, pressure resistance)

Send your message to us

Square and Round Ductile Casting Iron Manhole Cover EN124 in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 kg

- Supply Capability:

- 4100 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches