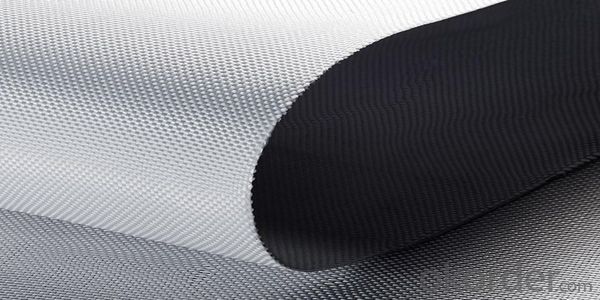

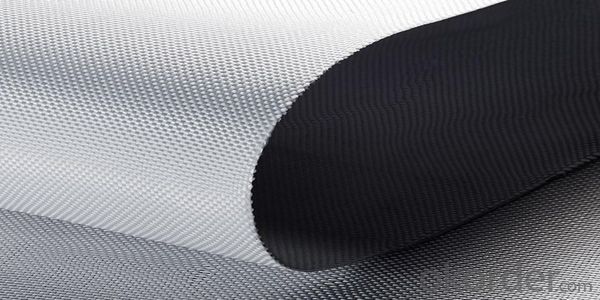

Spunbond Non Woven Geotextiles Industrial Nonwoven fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

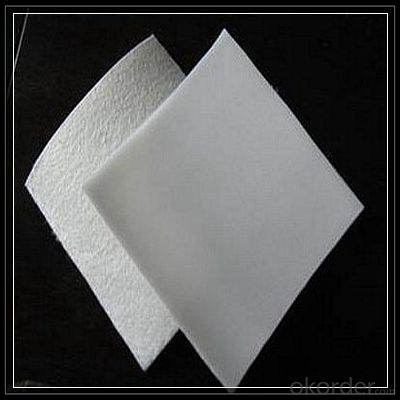

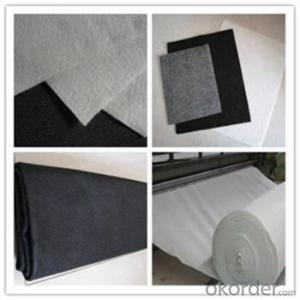

Nonwoven geotextiles consist of fibers that are continuous filament or short staple fibers. These fibers are then Nonwoven geotextiles Image bonded together by various processes that can include a needling process that intertwines the fibers physically (needlepunched), or a chemical / thermal bonding operation that fuses adjacent fibers together. The resulting nonwoven geotextiles have a random fiber orientation with high porosity and permeability, but indirect and unpredictable openings, a thickness ranging from thick felt to a relatively thin fabric, and low modulus and high elongation (needlepunched).

Non Woven Geotextile Application:

(1) artificial filling foundation movement of ground water.

(2) gravel filter layer surrounding the periphery of the drain pipe drain.

(3) in water conservancy projects wells, relief wells or inclined pipe filter.

(4) for retaining wall backfill reinforcement, or for anchored retaining wall panel.

(5) reinforced flexible pavements, crack repair roads, prevent the reflection cracks of pavement.

(6) in ternal vertical or horizontal drainage, dissipation of pore water pressure in soil.

(7) water impermeable geomembrane dam or embankment in the lower part of the back or the concrete.

(8) the isolation layer between the road ballast and subgrade, isolation layer or between the embankment and soft foundation.

(9) the isolation layer soil between highway, airport, railway ballast and artificial rockfill and soil fabric.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles contribute to erosion control on slopes?

- Geotextiles contribute to erosion control on slopes by providing stability and reinforcement to the soil. They act as a barrier that prevents soil particles from being washed away by water or wind. The geotextiles also promote vegetation growth and root development, further enhancing their erosion control capabilities.

- Q: How are geotextiles affected by chemical exposure?

- Geotextiles can be affected by chemical exposure depending on the type and concentration of the chemicals. Some chemicals can degrade or weaken the geotextile fibers, reducing their overall strength and effectiveness. Others may cause discoloration or chemical reactions that alter the properties of the geotextile. Therefore, it is essential to consider the compatibility of geotextiles with specific chemicals to ensure their long-term performance and integrity in various applications.

- Q: Are geotextiles poisonous?

- Geotextile is not toxic, the production of geotextile raw materials are polyester (PET) or polypropylene (PP). Polyester and polypropylene have become daily necessities. Many of the mineral water bottles are also produced by PET and PP raw materials.

- Q: How to determine the nominal breaking strength of filament spunbonded nonwoven geotextile

- You can use a dedicated geotextile strong test machine detected.

- Q: How are geotextiles affected by biological factors?

- Geotextiles can be affected by biological factors such as the growth of vegetation and the presence of microorganisms. Vegetation can penetrate and grow through geotextiles, reducing their effectiveness in providing separation and reinforcement. In addition, microorganisms can cause degradation of the geotextile material over time, compromising its structural integrity. Therefore, it is important to consider and manage these biological factors when using geotextiles in various applications.

- Q: What is the waterproof selection of artificial lake? How to build?

- Geotextile is the water, but the soil, from the role of anti-filter geomembrane is impermeable, like plastic film geotextile is a non-woven, as well as handbags, disposable health supplies, etc. I am the production of this wish smooth

- Q: Geotextile construction requirements of the use of adhesive specifications

- Hello, geotextile construction is very simple, laying with less cutting, less overlap for the principle. Take the head set aside about 25 cm. Using double take the head, sew two lines. This is in principle to ask this, the general construction can not do so carefully. Huazhi geotechnical materials manufacturers to answer, need to talk.

- Q: I'm looking for the fabric that goes between gravel and the ground (for a gravel driveway).

- you can get this at wicks do it all (now focus) or any good building merchants

- Q: What is the difference between woven and non-woven geotextiles?

- Woven geotextiles are made by weaving continuous individual yarns together, creating a strong and durable fabric. On the other hand, non-woven geotextiles are made by bonding or felting together synthetic fibers, resulting in a fabric that is not as strong or durable as woven geotextiles. Woven geotextiles provide higher tensile strength, better filtration, and are typically used in applications that require greater longevity and stability. Non-woven geotextiles, while less durable, are often used for filtration and separation purposes due to their high water flow rates and ability to retain fine particles.

- Q: How do geotextiles contribute to the cost-effectiveness of construction projects?

- Geotextiles contribute to the cost-effectiveness of construction projects by providing various benefits. They act as a barrier against soil erosion, reducing the need for expensive erosion control measures. Geotextiles also enhance soil stability, allowing for the use of less expensive and readily available fill materials. Additionally, they improve drainage and filtration, minimizing the need for costly drainage systems. Overall, geotextiles help optimize construction processes, reduce material and labor costs, and extend the lifespan of structures, making them a cost-effective choice for construction projects.

Send your message to us

Spunbond Non Woven Geotextiles Industrial Nonwoven fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords