Spray Anti-Rust Aerosol Can,1st Class Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Brief description

Content: insecticide

Size: 52X195mm

Printing: CMYK printing as Per Customer Design

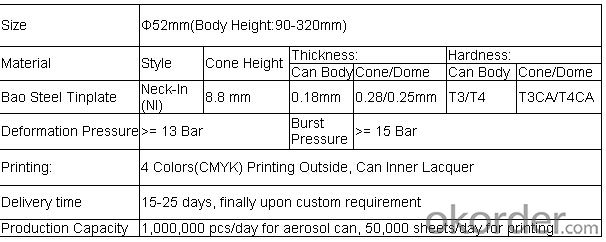

2.Detailed Specification

3. Usage:

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

4. Package:

5. Appearance Specifications

Diameter(mm) | Type | Straight(mm) |

45mm | Necked-in | 80-220 |

52mm | Necked-in | 80-300 |

52mm | Straight | 76-200 |

57mm | Necked-in | 90-240 |

60mm | Necked-in | 90-240 |

60mm | Straight | 80-300 |

65mm | Necked-in | 80-240 |

65mm | Straight | 80-240 |

6.FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s request

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q: What are the main challenges in tinplate coating?

- One of the main challenges in tinplate coating is achieving consistent and uniform coverage on the surface of the tinplate. This requires specialized equipment and precise control of the coating process parameters, such as temperature, speed, and viscosity of the coating material. Additionally, maintaining adhesion between the tinplate and the coating is another challenge, as any defects or inconsistencies in the adhesion can lead to corrosion or peeling of the coating. Lastly, ensuring that the coating is resistant to external factors such as moisture, chemicals, and abrasion is crucial for the long-term durability and performance of tinplate products.

- Q: What are the typical finishing options for tinplate products?

- The typical finishing options for tinplate products include painting, printing, coating, embossing, and varnishing. These options not only enhance the appearance of the tinplate products but also provide protection against corrosion and improve overall durability.

- Q: What are the main challenges in tinplate welding and soldering?

- Some of the main challenges in tinplate welding and soldering include ensuring proper surface preparation to achieve good adhesion, dealing with the thin gauge of tinplate which can make it more prone to warping or burning, and finding suitable fluxes and solder alloys that can effectively bond with tinplate due to its unique properties. Additionally, the presence of tin oxide on the surface of tinplate can hinder the formation of strong welds or solder joints, requiring special techniques or treatments to address this issue.

- Q: What are the main factors affecting tinplate market growth?

- The main factors affecting tinplate market growth include the demand for packaged food and beverages, economic growth and industrialization, advancements in technology and packaging techniques, government regulations and policies, and the sustainability and recyclability of tinplate as a packaging material.

- Q: How does tinplate contribute to sustainable packaging?

- Tinplate contributes to sustainable packaging by being highly durable, recyclable, and resistant to corrosion. It can be reused multiple times, reducing the need for new materials. Tinplate also provides excellent protection to the packaged goods, reducing food waste and extending product shelf life. Additionally, its recyclability helps in reducing the environmental impact by minimizing waste generation and conserving resources.

- Q: What are the different types of tinplate printing techniques?

- There are three main types of tinplate printing techniques: lithography, silk screen printing, and varnishing.

- Q: What are the advantages of using tinplate for HVAC components?

- There are several advantages of using tinplate for HVAC components. Firstly, tinplate is highly resistant to corrosion, which is crucial for HVAC systems that are exposed to moisture and varying temperatures. Secondly, tinplate has excellent thermal conductivity, allowing for efficient heat transfer within the system. Additionally, tinplate is lightweight yet strong, making it easy to handle and install while ensuring durability. Lastly, tinplate is a sustainable material as it is fully recyclable, aligning with the growing demand for eco-friendly HVAC solutions.

- Q: How is tinplate tested for quality and performance?

- Tinplate is tested for quality and performance through various methods such as visual inspection, thickness measurement, adhesion testing, corrosion resistance evaluation, and mechanical property analysis. Visual inspection involves assessing the surface for any defects or irregularities. Thickness measurement ensures the tin coating meets the required standards. Adhesion testing checks the bond strength between the tin and base metal. Corrosion resistance evaluation examines the tinplate's ability to withstand corrosion. Mechanical property analysis includes tests for strength, hardness, ductility, and formability to ensure it meets the desired performance requirements.

- Q: How is tinplate affected by different types of food products?

- Tinplate can be affected by different types of food products due to their varying acidity levels and ingredients. Foods that are highly acidic or contain high levels of salt can cause corrosion of the tin coating, leading to the potential transfer of tin to the food and affecting its taste and quality. Additionally, foods with strong flavors or odors can interact with the tinplate, potentially altering the taste and aroma of the food. It is important to ensure proper packaging and storage conditions to maintain the integrity of the tinplate and preserve the quality of the food product.

- Q: What are the main factors influencing the growth of the tinplate industry?

- The main factors influencing the growth of the tinplate industry include increasing demand for packaged food and beverages, expanding urbanization and industrialization, advancements in technology leading to improved production processes, and the growing awareness about the benefits of metal packaging such as durability, recyclability, and food safety. Additionally, economic growth in emerging markets and the rising disposable income of consumers are also driving the growth of the tinplate industry.

Send your message to us

Spray Anti-Rust Aerosol Can,1st Class Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords