Anti-Rust Aerosol Can For Spray, Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 PCS

- Supply Capability:

- 30000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Brief description

Content: insecticide

Size: 52X195mm

Printing: CMYK printing as Per Customer Design

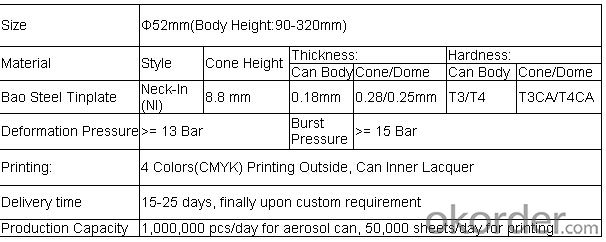

2.Detailed Specification

3. Usage:

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

4. Package:

5. Appearance Specifications

Diameter(mm) | Type | Straight(mm) |

45mm | Necked-in | 80-220 |

52mm | Necked-in | 80-300 |

52mm | Straight | 76-200 |

57mm | Necked-in | 90-240 |

60mm | Necked-in | 90-240 |

60mm | Straight | 80-300 |

65mm | Necked-in | 80-240 |

65mm | Straight | 80-240 |

6.FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s request

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q: Are there any health concerns associated with tinplate packaging?

- Yes, there are potential health concerns associated with tinplate packaging. Tinplate is coated with a thin layer of tin to prevent corrosion, but this coating can contain small amounts of lead, which is a harmful substance if ingested. Additionally, there is a risk of migration of other harmful substances from the packaging into the food or beverage it contains. Therefore, it is important to ensure that tinplate packaging is properly regulated and that manufacturers comply with food safety standards to minimize potential health risks.

- Q: How does tinplate contribute to the reduction of food waste?

- Tinplate contributes to the reduction of food waste by providing a durable and protective packaging solution for various food products. Its corrosion-resistant properties and airtight seal help to maintain the freshness and extend the shelf life of food items. This ensures that less food goes to waste due to spoilage or contamination, ultimately aiding in the reduction of food waste.

- Q: Can tinplate packaging be used for household products?

- Yes, tinplate packaging can be used for household products. Tinplate has excellent durability, corrosion resistance, and can be easily shaped into various forms. It is commonly used for packaging food, beverages, and other household items such as cleaning products, cosmetics, and personal care items.

- Q: What are the benefits of using tinplate for paint cans?

- One of the main benefits of using tinplate for paint cans is its exceptional durability and resistance to corrosion. Tinplate is a coated steel material that provides a protective barrier against moisture, preventing rusting and extending the lifespan of the paint cans. Additionally, tinplate is a lightweight material, making it easy to handle and transport. It also offers excellent recyclability, making it an environmentally-friendly choice.

- Q: Can tinplate be used for packaging beverages?

- Yes, tinplate can be used for packaging beverages. Tinplate is a durable and corrosion-resistant material that can effectively protect the contents of beverage packaging from external factors such as light, moisture, and oxygen. It is commonly used for packaging canned beverages like soda, beer, and juices.

- Q: What are the advantages of using tinplate for automotive parts?

- Tinplate offers several advantages for automotive parts. Firstly, it provides excellent corrosion resistance, ensuring durability and long-lasting performance even in harsh environments. Secondly, it offers high strength and rigidity, making it suitable for various automotive applications that require structural integrity. Additionally, tinplate is lightweight, contributing to fuel efficiency and reducing the overall weight of the vehicle. Lastly, it allows for easy shaping and forming, enabling complex designs and customization options for automotive components.

- Q: What are the main market entry barriers for new players in the tinplate industry?

- The main market entry barriers for new players in the tinplate industry include high initial capital investment requirements for setting up production facilities, limited availability of raw materials, complex regulatory compliance and quality standards, established relationships and contracts between existing players and customers, and intense competition from established companies with economies of scale. Additionally, the industry's mature nature and consolidation make it difficult for new entrants to gain market share and establish brand recognition.

- Q: Can tinplate be used for packaging of frozen foods?

- Yes, tinplate can be used for packaging of frozen foods.

- Q: Raw material for zinc clad sheet? Can zinc clad plate replace tinplate?

- Zinc is very active, outdoor corrosion is the surface after the formation of Zinc Oxide, do you dare to drink drinks containing Zinc Oxide, you see, you can replace the tinplate?

- Q: What are the benefits of using tinplate for coins?

- There are several benefits of using tinplate for coins. Firstly, tinplate is a durable material that can withstand wear and tear, making it ideal for coins that are constantly being handled and circulated. Additionally, tinplate is rust-resistant, ensuring that the coins maintain their appearance and quality even in humid or wet conditions. Another advantage is that tinplate is relatively inexpensive compared to other materials, making it a cost-effective choice for producing coins in large quantities. Lastly, tinplate is highly recyclable, which aligns with the growing emphasis on sustainability and environmental consciousness in coin production.

Send your message to us

Anti-Rust Aerosol Can For Spray, Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 PCS

- Supply Capability:

- 30000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords