Empty Car Care Aerosol Tin Can 52mm, Prime Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 PCS

- Supply Capability:

- 300000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief description

Content: car care

Size: 52X250mm

Printing: CMYK printing as Per Customer Design

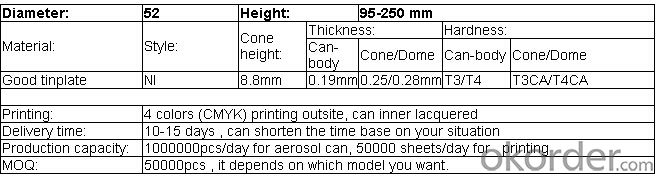

2.Detailed Specification

3. Usage

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

4.Package

5.Appearance Specifications

Diameter(mm) | Type | Straight(mm) |

45mm | Necked-in | 80-220 |

52mm | Necked-in | 80-300 |

52mm | Straight | 76-200 |

57mm | Necked-in | 90-240 |

60mm | Necked-in | 90-240 |

60mm | Straight | 80-300 |

65mm | Necked-in | 80-240 |

65mm | Straight | 80-240 |

6.FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s situation

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q: What are the common applications of tinplate?

- Tinplate is commonly used in the packaging industry for products such as food and beverages, as well as for aerosol cans, paint cans, and metal closures. It is also used in the manufacturing of electrical components, automotive parts, and various household items.

- Q: How does tinplate compare to stainless steel in terms of properties and applications?

- Tinplate and stainless steel differ in terms of properties and applications. Tinplate is a steel sheet coated with a thin layer of tin, providing it with corrosion resistance and a shiny appearance. On the other hand, stainless steel is an alloy containing chromium, providing it with exceptional corrosion resistance and high strength. In terms of properties, stainless steel outperforms tinplate. Stainless steel offers superior corrosion resistance, even in harsh environments, making it suitable for applications where durability is crucial. It also has excellent heat resistance and can withstand high temperatures. Tinplate, although corrosion-resistant, is less durable and has a lower melting point. Regarding applications, tinplate is commonly used for food packaging, beverage cans, and other consumer products due to its excellent ability to preserve and protect the contents. The tin layer prevents the steel from coming into contact with the packaged goods, ensuring their safety and extending shelf life. Stainless steel, on the other hand, finds extensive use in industries such as construction, automotive, medical, and kitchen appliances. Its strength, corrosion resistance, and hygienic properties make it ideal for structural components, surgical instruments, cutlery, and more. Overall, while tinplate is favored for its cost-effectiveness and specific packaging applications, stainless steel offers superior properties and versatility, making it suitable for a wide range of demanding industrial and domestic applications.

- Q: How is tinplate coated with metallic coatings?

- Tinplate is coated with metallic coatings through a process called electroplating. In this process, a tinplate sheet is immersed in a bath containing the desired metal ions, such as tin or chromium. An electric current is then passed through the bath, causing the metal ions to bond with the surface of the tinplate, resulting in a uniform metallic coating. This coating enhances the tinplate's corrosion resistance and provides a decorative finish.

- Q: How does tinplate contribute to the preservation of aerosol products?

- Tinplate contributes to the preservation of aerosol products through its excellent barrier properties. The tin coating on the steel provides a protective layer that prevents the metal from reacting with the contents of the aerosol can, thus preserving the quality and efficacy of the product. Additionally, tinplate cans offer resistance to corrosion and provide a hermetic seal, preventing any external elements from contaminating the aerosol contents.

- Q: What are the advantages of using tinplate for stationery?

- One advantage of using tinplate for stationery is its durability. Tinplate is known for its strength and resistance to corrosion, making it highly durable and long-lasting. This ensures that stationery items made from tinplate, such as pencil cases or storage tins, can withstand regular use and maintain their functionality over time. Additionally, tinplate is also a versatile material that can be easily shaped and molded into various designs, allowing for creative and aesthetically pleasing stationery products.

- Q: What are the main market entry barriers for new players in the tinplate industry?

- The main market entry barriers for new players in the tinplate industry include high capital requirements for setting up manufacturing facilities, the need for specialized equipment and technology, established brand loyalty among customers, economies of scale enjoyed by existing players, and stringent regulatory requirements. Additionally, the industry's long-standing relationships with suppliers and customers can make it challenging for new entrants to establish their presence and compete effectively.

- Q: What are the different methods of storing tinplate packaging?

- Some of the different methods of storing tinplate packaging include stacking the tinplates on shelves or pallets, organizing them in bins or containers, using racks or hooks to hang them, or placing them in specialized storage cabinets or drawers. It is important to ensure that the storage environment is clean, dry, and free from any potential sources of damage such as moisture, extreme temperature, or direct sunlight.

- Q: What are the main factors influencing the growth of the tinplate market?

- The main factors influencing the growth of the tinplate market include the increasing demand for packaged food and beverages, the rising preference for eco-friendly and sustainable packaging materials, technological advancements in the production process, and the expanding applications of tinplate in various industries such as electronics and automotive. Additionally, the growing population, urbanization, and changing consumer lifestyles are also driving the demand for tinplate packaging solutions, contributing to the market's growth.

- Q: What are the main trends in tinplate recycling?

- The main trends in tinplate recycling include increased awareness and adoption of recycling initiatives, technological advancements in sorting and processing methods, and the promotion of circular economy principles to minimize waste and maximize resource efficiency.

- Q: What are the main factors influencing the price volatility of tinplate?

- The main factors influencing the price volatility of tinplate include fluctuations in demand and supply, changes in production costs, global economic conditions, geopolitical events, and government regulations and policies. Additionally, factors like changes in exchange rates, technological advancements, and environmental concerns can also impact the price volatility of tinplate.

Send your message to us

Empty Car Care Aerosol Tin Can 52mm, Prime Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 PCS

- Supply Capability:

- 300000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords