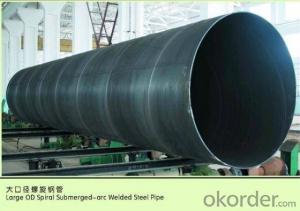

SPIRAL STEEL PIPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

| C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050 | <0.045 | <0.030 | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05 | <0.045 | <0.030 | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045 | <0.045 | <0.030 | >235 | 375-500 | 24-26 |

Q345 | <0.20 | 1.0-1.6 | <0.040 | <0.040 | <0.55 | >345 | 470-630 | 21-22 |

- Q: What are the advantages of using steel pipes in irrigation systems?

- There are several advantages of using steel pipes in irrigation systems. Firstly, steel pipes are highly durable and can withstand harsh weather conditions and heavy loads, ensuring a long lifespan. Secondly, they have a high tensile strength, which means they can handle high pressure and water flow rates without the risk of bursting or leaking. Additionally, steel pipes are resistant to corrosion, which is crucial for maintaining water quality and preventing contamination. Lastly, steel pipes are easy to install and maintain, making them cost-effective in the long run.

- Q: What is the typical diameter range for steel pipes?

- The typical diameter range for steel pipes can vary depending on the specific application and industry requirements. However, in general, steel pipes can have diameters ranging from as small as 0.5 inches (12.7 millimeters) up to several feet (over a meter) in diameter. The most commonly used steel pipes for various purposes, such as plumbing, construction, and transportation of fluids or gases, typically fall within the range of 1/2 inch (13 millimeters) to 36 inches (914 millimeters) in diameter. It is important to note that larger diameter steel pipes are often used for industrial applications, such as oil and gas pipelines, while smaller diameter pipes are commonly used for residential and commercial plumbing systems.

- Q: How do you determine the weight per foot of a steel pipe?

- To ascertain the weight per foot of a steel pipe, there are two primary factors to consider: the pipe's thickness and diameter. Initially, it is necessary to measure the pipe's outer diameter (OD) and wall thickness (WT) using either a caliper or a measuring tape. Upon obtaining these measurements, the inner diameter (ID) can be determined by subtracting twice the wall thickness from the outer diameter (ID = OD - 2 * WT). Subsequently, utilize the formula for the cross-sectional area of the pipe (A = π * (OD^2 - ID^2) / 4) to calculate the cross-sectional area. Lastly, multiply the cross-sectional area by the steel's density, typically around 490 pounds per cubic foot, to derive the weight per foot of the steel pipe. Weight per foot (WPF) = A * 490 It is vital to acknowledge that this calculation provides an approximation of the weight per foot, as manufacturing tolerances and slight variations in steel density may impact the actual weight. Thus, it is advisable to employ this calculation as a reference and consult the manufacturer's specifications for more accurate information.

- Q: Can steel pipes be used for underground sewerage systems?

- Yes, steel pipes can be used for underground sewerage systems. Steel pipes are strong and durable, making them suitable for carrying sewage underground. They have a high resistance to corrosion and can withstand the pressure and load of the ground above. Steel pipes also have a long lifespan and are resistant to environmental factors such as moisture, chemicals, and temperature fluctuations. Additionally, steel pipes can be easily welded, making installation and repairs more convenient. However, it is important to ensure that the steel pipes are properly coated or lined to prevent corrosion and to comply with local regulations and standards for underground sewerage systems.

- Q: What are the common protective coatings used on the inner surface of steel pipes?

- The common protective coatings used on the inner surface of steel pipes include epoxy, polyurethane, and cement mortar coatings. These coatings provide corrosion resistance, prevent the formation of scales, and improve the durability and lifespan of the pipes.

- Q: How are steel pipes protected against underground corrosion?

- Steel pipes are protected against underground corrosion through a process called cathodic protection. This involves the use of sacrificial anodes or impressed current systems, which help to create a protective electrical current that prevents the steel from corroding. Additionally, coatings and wraps are applied to the pipes to provide an additional layer of protection against corrosion.

- Q: Are steel pipes suitable for use in sewage treatment plants?

- Yes, steel pipes are suitable for use in sewage treatment plants. Steel pipes are durable, corrosion-resistant, and have a long lifespan, making them ideal for handling the harsh conditions and corrosive substances found in sewage systems. Additionally, steel pipes offer high strength and are capable of withstanding high-pressure flows, making them a reliable choice for sewage treatment plants.

- Q: Can steel pipes be used for underground air supply systems?

- Indeed, underground air supply systems can make use of steel pipes. Due to their robustness, endurance, and ability to withstand external forces like corrosion and impact, steel pipes are frequently employed in underground settings. They possess the capacity to endure the pressure and temperature prerequisites of air supply systems while also being effortlessly installed below ground. Moreover, steel pipes boast an extended lifespan, rendering them a financially prudent option for underground air supply systems. Nonetheless, when selecting the suitable steel pipes for a particular underground air supply system, it is crucial to take into account factors such as soil conditions, potential for corrosion, and local regulations.

- Q: How are steel pipes used in the manufacturing of geothermal systems?

- Steel pipes are used in the manufacturing of geothermal systems for their durability and heat conductivity. They are used to transport fluids, such as water or steam, between the geothermal source and the heat pump or power generator. Steel pipes can withstand high temperatures and pressures, making them ideal for the harsh environment of geothermal systems. Additionally, their corrosion resistance ensures the longevity and efficiency of the system.

- Q: Can steel pipes be used for LNG terminals?

- Yes, steel pipes can be used for LNG terminals. Steel pipes are commonly used in the construction of LNG terminals due to their durability, strength, and resistance to extreme temperatures. Additionally, steel pipes can effectively handle the high-pressure requirements of LNG transportation and storage.

Send your message to us

SPIRAL STEEL PIPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords