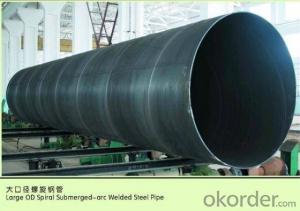

SPIRAL STEEL PIPE 16‘‘-48’‘

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

| C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050 | <0.045 | <0.030 | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05 | <0.045 | <0.030 | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045 | <0.045 | <0.030 | >235 | 375-500 | 24-26 |

Q345 | <0.20 | 1.0-1.6 | <0.040 | <0.040 | <0.55 | >345 | 470-630 | 21-22 |

- Q: What are the common applications of steel pipes in the water distribution system?

- Steel pipes are commonly used in water distribution systems for various applications such as transporting water from treatment plants to homes, buildings, and industries, as well as for underground water mains and fire hydrant systems.

- Q: What are the quality control measures for steel pipe production?

- Quality control measures for steel pipe production typically involve various inspections and tests at different stages of the manufacturing process. Some of the key measures include: 1. Raw material inspection: Ensuring that the steel used for pipe production meets specified standards for chemical composition, mechanical properties, and dimensional accuracy. 2. Dimensional inspection: Checking the outer diameter, wall thickness, and length of the pipes to ensure they meet the required specifications. 3. Welding inspection: Verifying the quality of welds by conducting non-destructive tests, such as ultrasonic or radiographic testing, to detect any defects or discontinuities. 4. Surface inspection: Examining the pipe surface for any defects, such as scratches, pits, or corrosion, which can affect the overall quality and performance. 5. Mechanical testing: Performing tests like tensile strength, yield strength, and impact resistance to assess the mechanical properties of the pipes and ensure they meet the desired standards. 6. Pressure testing: Subjecting the pipes to hydrostatic or pneumatic pressure tests to verify their ability to withstand the intended operational pressures without leakage or failure. 7. Coating inspection: Checking the quality and uniformity of any protective coatings or linings applied to the pipes to prevent corrosion or other forms of deterioration. 8. Documentation and traceability: Maintaining records of all inspections, tests, and certifications to provide traceability and ensure compliance with relevant industry standards and customer requirements. These quality control measures help to ensure that steel pipes are manufactured to the highest standards, possess the required mechanical and dimensional properties, and are fit for their intended application.

- Q: Is the PVC tube a plastic tube or a plastic tube?.

- It's plastic tubePolyvinyl chloride (Poly, Vinyl, Chloride, PVC)PVC is a VCM monomer (vinyl, chloride, monomer), in peroxide, azo compounds and other initiators;

- Q: How do steel pipes perform in high-altitude applications?

- Steel pipes perform well in high-altitude applications due to their inherent strength and durability. The high tensile strength of steel allows it to withstand the harsh conditions and extreme temperature variations experienced at high altitudes. Furthermore, steel pipes are resistant to corrosion, making them suitable for use in high-altitude environments where exposure to moisture and atmospheric gases is common. Overall, steel pipes are a reliable choice for various high-altitude applications, including oil and gas transportation, construction, and infrastructure development.

- Q: How are steel pipes measured?

- Steel pipes are typically measured by their outer diameter (OD) and wall thickness. The OD is measured using a caliper or tape measure, while the wall thickness is determined using specialized tools like ultrasonic gauges or micrometers. These measurements are crucial for determining the pipe's size, strength, and suitability for various applications.

- Q: How are steel pipes used in the manufacturing of pressure vessels?

- Steel pipes are commonly used in the manufacturing of pressure vessels as they provide the necessary strength and durability to withstand high internal pressure. These pipes are welded or seamless and are often used as the main structural component of the vessel. They allow for the efficient flow of fluids or gases within the vessel and provide a reliable and secure containment system for various industrial applications.

- Q: How are steel pipes used in the manufacturing of marine applications?

- Steel pipes are commonly used in the manufacturing of marine applications due to their durability, corrosion resistance, and high strength. These pipes are utilized for various purposes, such as constructing ship hulls, offshore platforms, and underwater pipelines. They are also employed in the manufacturing of marine equipment, including pumps, valves, and heat exchangers. Furthermore, steel pipes are crucial for transporting fluids, such as oil, gas, and water, in marine environments. Overall, steel pipes play a vital role in ensuring the reliability and efficiency of marine applications.

- Q: What are the different types of coatings used for external protection of steel pipes?

- There are several types of coatings used for external protection of steel pipes. Some common ones include epoxy coatings, polyethylene coatings, coal tar coatings, and fusion bonded epoxy coatings. Each type of coating offers specific benefits and is chosen based on factors such as the environment, type of exposure, and desired level of protection.

- Q: What is the maximum pressure that steel pipes can handle?

- The maximum pressure that steel pipes can handle varies depending on factors such as the specific grade of steel, diameter, and wall thickness of the pipe. However, steel pipes are known for their high strength and durability, and they can typically handle pressures ranging from a few hundred to several thousand pounds per square inch (psi).

- Q: What are the safety measures to be followed while working with steel pipes?

- There are several safety measures that should be followed while working with steel pipes. Firstly, it is important to wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots to protect against potential hazards. Secondly, workers should be cautious of sharp edges or burrs on the pipes and handle them with care to avoid cuts or injuries. Additionally, proper lifting techniques should be employed when moving heavy steel pipes to prevent strains or back injuries. It is also crucial to secure pipes properly during transport or storage to prevent accidents. Finally, workers should be trained on the safe use of tools and equipment associated with steel pipe work to minimize the risk of accidents or damage.

Send your message to us

SPIRAL STEEL PIPE 16‘‘-48’‘

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords