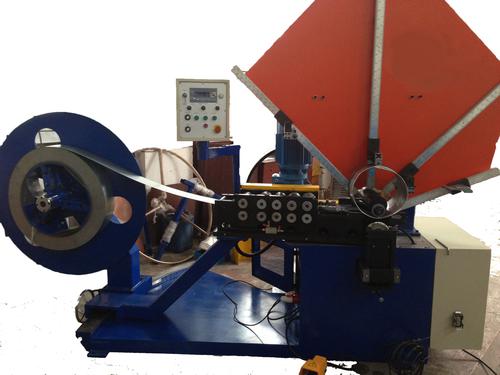

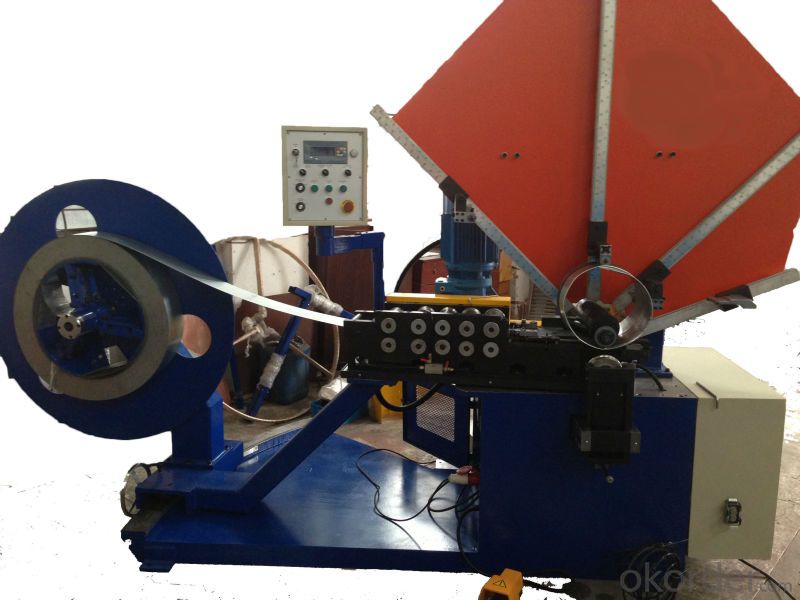

spiral duct making machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

packaging

wooden packaging(2.8*2.1*2.2m)

Ocean shipping or Road transport

Guarantee within one year

Spiral Tube forming machine

Special model easy to adjust

High-speed synchro flying cutting system

CNC operation convenient for worker

For processing of tubes in stainless steel,galvanized mild steel ,aluminum and copper

PLC automatic control

Automatic tube ejection device

Automatic setting and length measuring device

Automatic counting system for number of tubes producedi

Tube Diameter | ¢85-¢1500mm |

Tube Length | 100-8000mm |

Thickness | 0.4-1.0mm(galvanization steel plate) 0.4-0.6mm(stainless steel) |

Strip Width | 137mm-140mm |

Strip Speed | 1-38m/min |

Dimensions | 2100*2000*2850mm |

Weight | 2200kg |

Controlling System | PLC automatic control |

Main Motor Power | 5.5kw |

Cutting Power | 4kw |

Gas Power | 0.5-0.7kmp |

Electric | 380v/50HZ |

- Q: How does the pipe machine operate?

- The contents of the inspection requirements of the equipment required to fill in the site inspection records, a person in charge of the inspection and signature; for the discovery of equipment requirements in a timely manner reported, supervisors and workshop director to make comments, and report the results reported production

- Q: Pipe machine on the bearing what are the requirements

- A PLC programmable control technology, the whole process of automatic control to effectively avoid the factors that affect the impact.

- Q: What kind of plastic pipe is divided?

- Because of its light weight, corrosion resistance, beautiful appearance, no bad smell, easy processing, easy construction and other characteristics, in the construction project has been more and more widely used.

- Q: What is the difference between galvanized welded steel pipe and galvanized steel pipe?

- Welded black tube through the surface treatment, removal of pipe surface oxide and other debris, can increase the adhesion of galvanized layer in the tube matrix.

- Q: What is the purpose of each mold of stainless steel pipe machine?

- The mold on the stainless steel pipe is divided into mold, mold, mold, mold, mold, mold, mold Specify the tube, tube / square tube using a different mold)

- Q: What is the stainless steel pipe machine?

- Stainless steel with welding, the need for rapid cooling water, and through the three groups of grinding wheel surface grinding, so that the weld flat, no feel.

- Q: The introduction of the pipe machine is

- The main pipe is divided into two major: one of which is a common high-frequency welded pipe machine, the other is a stainless steel pipe machine, high-frequency welded pipe machine is mainly used for the production of various iron pipes, water pipes, etc .;

- Q: Cement pipe machinery and equipment how to work?

- Rotate, then start the feeder from one end of the mold to the other end of the feed, when the concrete is higher than the mold ring 3-5mm, the concrete directly with the spindle contact, relying on the weight of the mold and the weight of concrete compaction reinforced concrete drainage pipe

Send your message to us

spiral duct making machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords