Spiral Paper Tube Winding Machine with high quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Description

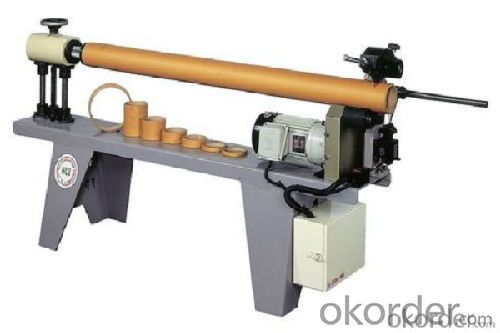

Hot Sell Spiral Paper Tube Winding Machine

2.Main Features

Condition: New

Product Type: Paper Core Machine

Processing Type: Winding Machine

Place of Origin: China (Mainland)

Voltage: 3*380 V

Power(W): 15 KW

Dimension(L*W*H): 5500*2000*2000 mm

Weight: 4000 KG

Certification: CCIS

Warranty: 1 year

3. Images

4. Specifications

Hot Sell Spiral Paper Tube Winding Machine Technical Parameter

Technical Parameter | Control system | |||

Number of roller | 3-16 layer | PLC controller | Delta DVP14SS2 | |

Tube diameter | 20-200 mm | Touch screen | MCGS TPC7062 | |

Tube wall-thickness | 1-10 mm | Transducer | YASKAWA 7.5 KW | |

Core mould fixed way | Flank chuck | Electric part | Schneider | |

Winding head | 4 | Single part | Omron | |

Cutting way | Round knife | Pneumatic part | AIRTAC | |

Gluing way | Single / double sides | Fix length way | Optoelectronic switch/encode | |

Operator | 1-2 person | Equip device | ||

Winding speed | 3-30 m/min | Paper shelf type | Integral reel stand | |

Speed control | Transducer | Auto fall tube shelf | Have | |

Driving system | Glue shelf | Have | ||

Main motor | 7.5 KW | Belts | 4 | |

Reducer type | WPO155 JIACHENG | Core mould | 2 | |

Cutting motor | Stepper motor | Cut up-down control | Y lead screw+ stepper motor | |

Glue pump | 1.5 KW | Cut left-right control | Z lead screw+ servo motor | |

- Q: What is the design basis of automated packaging?! Just for today!

- Greatly improve the degree of automation of process flowA few years ago, automation technology accounted for only 30% of the design of packaging machinery, now has accounted for more than 50%, a large number of micro computer design and mechanical and electrical integration control. To improve the packaging machinery automation, one is to increase productivity; the two is to improve the flexibility and agility equipment; three is to improve the ability of packaging machinery to complete the complex action, namely the manipulator to complete the packaging process. Such as chocolate packaging has been achieved, with mechanical hand instead of the original manual. Automatic design of packaging machinery has the following two main characteristics:

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q: What is the price of a small jujube packing machine?

- Mainly see what some requirements, automatic metering packaging or vacuum packaging machine, after understanding can determine the price.

- Q: What are the main functions of packaging machinery and equipment?

- Packaging machinery can be realized in the packaging process, including filling and wrapping,

- Q: What machine does the packing carton machine have?

- Packaging equipment including: automatic strapping machine, automatic sealing machine, winding (wrapping) machine, sealing and cutting / shrink machine, vacuum packing machine, automatic strapping machine band and hand tools. Transport equipment mainly include: conveyor belt, roller conveyor, conveyor chain plate, plug-in production line, chain conveyor, conveyor belt etc..

- Q: What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q: What's the fastest packing machine?

- Depending on the characteristics of your material, the speed is adjustable!

- Q: Energy saving reform of packaging machine

- A) the main control circuit is composed of man-machine interface (text display), frequency converter and programmable logic controller (PLC), which constitute the control core;B) the temperature control circuit is composed of an intelligent temperature control meter, a solid state relay and a thermocouple element. The temperature control is accurate, the display is intuitive, and the setting is convenient;C) multi point tracking and detection by photoelectric switches and electromagnetic proximity sensors; 2) fully automatic pillow type working principle:With the improvement of automation, the operation, maintenance and routine maintenance of the packing machine are more convenient and simple, and the professional skill requirements of the operators are reduced. The quality of the product packaging is directly related to the temperature system, the speed accuracy of the main engine and the stability of the tracking system.

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard applies to the use of heat sealing glass paper, BOPP, PVC film and other packaging materials, packaging machine for carton box type items or single package or bag or several stacked and wrapped sealing, widely used in food, medicine, tobacco, cosmetics, stationery, audiovisual products etc.. This standard needs to be purchased.

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Ha ha, as you say, TV factories are closed down, every household has a TV, but every day there will be a lot of people buy tv.

Send your message to us

Spiral Paper Tube Winding Machine with high quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords