solid state high frequency welders from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

solid state high frequency welders from China

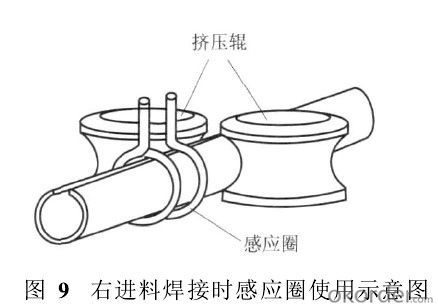

Solid State HF Welder made by Chaochang adopt Germany brand IXYS MOSFET and Fast recovery diode, using

induction heating as heating method , water cooling system and PLC control system. Until now we have made many succesful

solid state high frequency welders from China for pipe factory customers.

Product Name: Solid state high frequency welders

Application : Used for straight seam welding of carbon steel tube, galvanized pipe, aluminium tube etc.

Advantages of Solid state HF WELDER

1. HF welder is much more efficient compared with vacuum tube welders.

2. Solid state welders have a compact and modular design.

3. Vacuum tube welders have a lifetime span. Solid state HF welders have semiconductor components,

which has no life limit . So high frequency welder is more reliable compared with vacuum tube welders.

Configuration of QUALITY HF WELDER

1. Switch Rectifying Cabinet

2. Inverter Output Cabinet

3. Operation Console

4. Water-Water cooler or Air-Water cooler

5. 2-D adjustable bracket

6. Optical fiber

Composition

The whole set of solid state high frequency welders from China is composed of switch rectifying cabinet, inverter output cabinet, central control console,

2-D adjustable bracket device , water cooling system and one set air conditioner.

- Q: How does the pipe machine operate?

- Supervisors, pipe fittings in the transfer of the production team when the team leader and the engineers on their posts to use the equipment to be checked, not to the equipment to the get off work to continue to use the company according to the production and equipment operation to develop maintenance plans, minor and

- Q: Pipe machine on the bearing what are the requirements

- Equipment with length control device, the next chat length can be set according to their own requirements, can effectively reduce the loss of material head.

- Q: What kind of plastic pipe is divided?

- Plastic pipe is generally made of plastic resin as raw materials, adding stabilizers, lubricants, etc., to "plastic" approach in the pipe machine by extrusion processing.

- Q: What is the difference between galvanized welded steel pipe and galvanized steel pipe?

- Galvanized pipe: the use of galvanized carbon steel plate (or alloy steel plate), the pipe made of pipe profiles (square tube, pipe, rectangular tube, shaped tube, etc.), after high-frequency welding, quality inspection qualified factory

- Q: What is the purpose of each mold of stainless steel pipe machine?

- The mold on the stainless steel pipe is divided into mold, mold, mold, mold, mold, mold, mold Specify the tube, tube / square tube using a different mold)

- Q: What is the stainless steel pipe machine?

- Hello, stainless steel pipe machine from the machine and many different groups of molds; stainless steel belt from one head into the extrusion through different molds, during the welding by welding, so that steel into a sealed shape.

- Q: The introduction of the pipe machine is

- The main pipe is divided into two major: one of which is a common high-frequency welded pipe machine, the other is a stainless steel pipe machine, high-frequency welded pipe machine is mainly used for the production of various iron pipes, water pipes, etc .;

- Q: Cement pipe machinery and equipment how to work?

- Rotate, then start the feeder from one end of the mold to the other end of the feed, when the concrete is higher than the mold ring 3-5mm, the concrete directly with the spindle contact, relying on the weight of the mold and the weight of concrete compaction reinforced concrete drainage pipe

Send your message to us

solid state high frequency welders from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords