SPIRAL CARBON STEEL PIPE API 5L

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

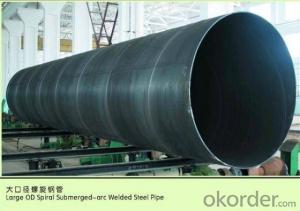

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

| C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050 | <0.045 | <0.030 | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05 | <0.045 | <0.030 | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045 | <0.045 | <0.030 | >235 | 375-500 | 24-26 |

Q345 | <0.20 | 1.0-1.6 | <0.040 | <0.040 | <0.55 | >345 | 470-630 | 21-22 |

- Q: What is the difference between carbon steel pipes and stainless steel pipes?

- The main difference between carbon steel pipes and stainless steel pipes lies in their composition. Carbon steel pipes are primarily made of iron and carbon, while stainless steel pipes contain iron, carbon, and a minimum of 10.5% chromium. This high chromium content in stainless steel pipes provides excellent corrosion resistance, making them suitable for various applications in industries like food processing, chemical, and oil & gas. On the other hand, carbon steel pipes are more cost-effective and have higher strength than stainless steel pipes, but they are more susceptible to corrosion and thus require regular maintenance and coating for protection.

- Q: How are steel pipes used in the construction of dams and water reservoirs?

- Steel pipes find widespread application in the construction of dams and water reservoirs owing to their remarkable durability, strength, and capacity to endure heavy loads and high pressure. These pipes serve multiple indispensable functions within the realm of dam and reservoir construction. A primary utility of steel pipes in these structures lies in their capacity to transport water. They are employed to convey water from its source, such as a river or stream, to the reservoir or dam. These pipes are engineered to withstand the elevated water pressure, ensuring a consistent flow of water to the reservoir. The durability of steel pipes enables them to remain intact even in the harshest environmental conditions. In addition to water conveyance, steel pipes are also utilized for drainage purposes. They are employed to establish drainage systems that help regulate the water level within the reservoir or dam. These pipes are strategically positioned to control the water flow and prevent potential flooding or overflow. Steel pipes are also integrated into the construction of spillways and outlets in dams and reservoirs. Spillways are designed to release excess water from the reservoir during heavy rainfall or when the water level exceeds predetermined thresholds. Steel pipes are employed in crafting these spillways to provide a controlled pathway for water discharge, thus averting any harm to the dam or surrounding areas. Moreover, steel pipes are employed in the construction of penstocks, which are large conduits that transport water from the reservoir to turbines in hydropower plants. The pressure generated by the water within these pipes propels the turbines, facilitating electricity generation. The robustness and durability of steel pipes are vital in ensuring the smooth and efficient operation of hydropower plants. All in all, steel pipes occupy an indispensable role in the construction of dams and water reservoirs. Their durability, strength, and ability to withstand high pressure render them an ideal choice for various aspects of these structures, including water transportation, drainage systems, spillways, and penstocks.

- Q: Can steel pipes be used for underground stormwater systems?

- Indeed, underground stormwater systems can utilize steel pipes. Renowned for their resilience and robustness, steel pipes are apt for enduring the pressure and burden of such systems. Furthermore, steel pipes possess remarkable resistance against corrosion, a crucial attribute when handling stormwater potentially laden with diverse pollutants. Nevertheless, it is imperative to adequately coat and safeguard the steel pipes to avert any potential corrosion or harm over time. Routine maintenance and inspections should also be undertaken to guarantee the integrity of the steel pipes and the overall efficacy of the underground stormwater system.

- Q: How to establish a concrete-filled steel tubular column model in ANSYS?

- A two unit model or a composite unit model can be adoptedTwo units are constructed of steel tubes and concreteA composite unit may be either a fiber element or a section conversion attribute

- Q: What are the common factors affecting the flow capacity of steel pipes?

- The flow capacity of steel pipes can be affected by several common factors. Firstly, the diameter of the pipe plays a crucial role. A larger diameter allows for a greater flow capacity because there is more area for the fluid to pass through. Secondly, the length of the pipe also affects flow capacity. Longer pipes tend to have higher frictional losses, which can decrease the flow capacity. Thirdly, the internal surface roughness of the steel pipe can impact flow capacity. Rough surfaces create more friction, resulting in a lower flow rate. Conversely, smooth pipes allow for smoother flow and higher flow capacity. The properties of the fluid being transported through the steel pipe are another important consideration. Factors such as viscosity, temperature, and density can all influence the flow rate. For example, highly viscous fluids have a lower flow capacity compared to less viscous fluids. Additionally, pressure drop along the length of the pipe is a significant factor. Friction, bends, and restrictions can all cause pressure losses, resulting in a lower flow capacity. The material of the steel pipe and its wall thickness also play a role. Different materials have varying properties that can impact flow rates. Moreover, thicker walls can reduce the internal diameter of the pipe, leading to a lower flow capacity. Lastly, the design and layout of the pipe system, including the presence of fittings, can impact flow capacity. Fittings such as valves, elbows, and tees can cause additional pressure drops and turbulence, reducing the overall flow rate. Considering these factors is essential when designing or evaluating a steel pipe system to ensure optimal flow capacity and efficiency.

- Q: What are the different types of joints used to connect steel pipes?

- There are several types of joints commonly used to connect steel pipes, including threaded joints, flanged joints, welded joints, and mechanical joints. Each type of joint has its own advantages and is chosen based on factors such as the application, pipe size, and pressure requirements.

- Q: How are steel pipes used in the marine industry?

- Steel pipes are widely used in the marine industry for various applications such as shipbuilding, offshore structures, and underwater pipelines. They provide strength, durability, and corrosion resistance, making them suitable for transporting fluids, gases, and other materials in harsh marine environments. Steel pipes are also used for constructing piers, docks, and oil rigs, as well as for supporting and reinforcing marine structures.

- Q: Can steel pipes be used for underground drainage in acidic soils?

- Yes, steel pipes can be used for underground drainage in acidic soils. However, it is important to consider the type of steel used and the corrosion resistance properties to ensure longevity and prevent potential damage from the acidic environment. Additionally, protective coatings or linings can be applied to the steel pipes to enhance their resistance to corrosion in acidic soils.

- Q: How do steel pipes perform in seismic zones?

- Steel pipes are commonly used in seismic zones due to their high strength and flexibility. They are able to withstand the dynamic forces and ground movements caused by earthquakes, offering excellent resistance to damage and deformation. The ductility and toughness of steel pipes allow them to absorb and dissipate energy during seismic events, reducing the risk of failure or collapse. Additionally, steel pipes can be designed and installed with proper reinforcement and connections to further enhance their performance in seismic zones.

- Q: Can steel pipes be used for fencing?

- Yes, steel pipes can be used for fencing. They are a popular choice for fencing due to their strength, durability, and ability to withstand harsh weather conditions. Steel pipes provide a sturdy and secure barrier, making them suitable for various fencing applications such as residential, commercial, and industrial settings.

Send your message to us

SPIRAL CARBON STEEL PIPE API 5L

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords