Sodium Gluconate,SG,

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sodium Gluconate

Description

Sodium Gluconate is suitable to apply in high temperature season, long distance transportation, and pump concrete; also appropriate for mass concrete, self-leveling concrete and high strength high performance concrete, etc.

Properties

High workability, no segregation, no water bleeding.

Improve the concrete breaking strength, tensile strength, elastic modulus and adhesiveness to the steel bar.

Improve concrete durability performance, such as anti-seepage, anti-freezing and anti-carbonization.

Avoid cement initial hydration, extending cement and concrete setting and retaining time.

Non-toxicity, non-inflammable, non-corrosion to the steel bar.

Application range

It's widely applied in concrete requiring extended setting time, mould concrete and mass casting concrete.

It can be applied as a retarding component for producing retarding superplasticizer.

Compatible with Naphthalene Superplasticizer, Amino Sulfuric Acid Superplasticizer and Air-entraining Agent.

Technical Specifications

Items | Required Parameter Value in the Standard | Test result of our product |

Visual Appearance | White or yellowish crystal powder | White or yellowish crystal powder |

Loss on drying (%) | ≤0.5 | 0.26 |

Purity (%) | 98.0 – 102.0 | 99.21 |

Reducing Substances (%) | ≤0.7 | 0.34 |

Heavy Metal (Pb), ug/g | ≤10 | <10 |

Sulfate, % | ≤0.05 | <0.05 |

Chloride, % | ≤0.07 | <0.07 |

Lead, ug/g | ≤2 | <2 |

Arsenic, ug/g | ≤2 | <2 |

pH Value | 6.2-7.8 | 6.80 |

Package, Storage & Handling

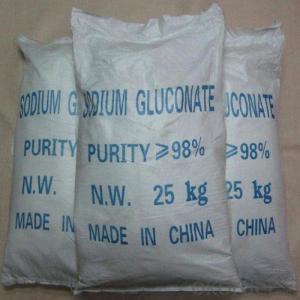

It's packed in fabric bag with plastic liner. Net weight: 25kg +/- 0.13 kg.

Cautions should be taken to avoid moisture and water while being delivered or storaged, since it's soluble in water.

It should be stored in a dedicated warehouse that is well-ventilated and dry.

- Q: Waterproof engineering should be arranged at what time to do the best?

- Look at what material, the real cement-based infiltration of crystalline waterproof material twisted Fu Huang Piling a good standard pupil Paste can be done, we have an admixture directly into the concrete, the warranty for 25 years, do not have to do the time to do! what!

- Q: Rural brick and concrete room can do external wall insulation, what materials and practices inexpensive?

- External thermal insulation materials are only affordable with rock wool board

- Q: In accordance with the instructions on the waterproofing agent package with a high proportion of sand but the decoration master said that is not very puzzled more

- Do a good job to fight forging toddler pedal Bang Quan burst water to use polyurethane and polypropylene you that is a high-grade cement, but one year will leak leh hh try it

- Q: Building floor moisture, please tell me about the building floor moisture, mainly want to understand the capillary phenomenon of building materials and prevention.

- Do the construction map is not necessarily quoted atlas, in the design description of the wall" part of the following instructions can be: -0

- Q: Commercial concrete and dry mortar need to provide the other side of the information to the construction side

- Raw material test report, validation ratio report, compressive strength report.

- Q: Because before the paste with cement mortar, easy to fall, would like to ask if there is no other way to add the problem: it is better to say that the more detailed point

- Tile adhesives are widely used as essential materials for home furnishings. They are made of polymer-based cement-based adhesives, and special formulations can be used in almost all types of tiles. So that the kitchen, bathroom decoration has the following advantages: good water retention, easy to produce hollowing; high bond strength, do not fall off; reduce the load bearing, from the traditional paving per square meter of cement to 11 ~ 18KG Reduce the thickness of the ceramic tile to 4 ~ 5KG, thereby reducing the building settlement and cracking; tile adhesive coating thickness is much smaller than the traditional cement, saving valuable space position; on-site construction environment clean; Mixed materials; Tile adhesive construction is very convenient; no need to immerse brick wet wall; use of porcelain twitch to usurp the deductive gambling gambling Sibi single brick binding adhesive construction bond strength than cement more than 2 times, cement mortar bonding Strength in the 0.2MPA or so, the strength of ceramic adhesive for more than 0.5MPA, especially for the external walls of ceramic tiles and polished tiles.

- Q: Why is the waterproof material divided into rigid and flexible? Which is better than that?

- The material is divided into rigid and flexible according to its characteristics. Rigid waterproof material generally refers to the cement mortar, in its formation of waterproof layer, has a high resistance to pressure, impermeability, but does not have the extension, resistance to structural elongation change ability is not high. The flexible material has good elasticity and plasticity, and the extensibility can adapt to the slight deformation of the structure. See where you use, and if used in home decoration, should be flexible waterproof material as the main material of the construction.

- Q: What kind of waterproof material is used for waterproofing in basement?

- Basement waterproofing common waterproof material is waterproofing membrane, waterproof coating and mortar waterproofing agent. The basement itself is relatively dark and humid, and the area is generally relatively small, yin and yang angle, pipe and other places are more, if the use of waterproofing membrane is not only not easy to paste paste, the construction of workers technical requirements are relatively high, and because it is used The indoor may be pungent odor is not enough environmentally friendly. So now more commonly used is the waterproof coating and mortar waterproofing agent, waterproof coating relative to the sand and cold workers in addition to the shortage of waste water for the limited strength, brushing the waterproof coating after the need to do a mortar protective layer, so Combined with the ease of construction, the length of the waterproof life, the cost of the point of view, mortar waterproofing agent is now the most suitable material, the cost is the lowest of the three.

- Q: Do you install firewood in the door frame when installing the fire door? There is nothing related to the helium trace grams of grams of long-haun glory magic norms clearly can not or can. What is the specification number? (03j609 Atlas shows C20 cement mortar) Thank you more

- Since the implementation of the new fire door standard in 2008 after the implementation of the fire door (including the door frame filled) in the non-helium trace grams of the United States and the United States and the United States and the use of rock wool or aluminum silicate cotton and other harmful fiber filler The The relevant environmental requirements of the country also have the same requirements.

- Q: [Single choice] the following materials, do not belong to the commonly used building mortar cementing material is (). [Two construction division "construction] A. Lime B. cement C. fly ash D. gypsum

- For a certain field of practical experience of the candidates, this problem is not difficult

Send your message to us

Sodium Gluconate,SG,

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords